14

RTR12 & RTA12 Series (Serial No. 884764-) Rotary Tillers 311-785M

8/12/14

Section 1: Assembly and Set-Up

Table of Contents

!

DANGER

Do not engage tractor PTO while hooking-up and unhooking

driveline or while someone is standing near the driveline. A

person’s body and/or clothing can become entangled in the

driveline resulting in serious injury or death.

!

WARNING

Do not use a PTO adaptor with a quick hitch. A PTO adapter

will increase strain on the tractor’s PTO shaft resulting in

possible damage to shaft and driveline.

!

DANGER

All guards and shields must be installed and in good working

condition at all times during tiller operation.

!

WARNING

Always disengage PTO, put gear selector in park or set park

brake, shut off tractor, remove ignition key, and wait for all

moving parts to come to a complete stop before dismounting

tractor.

!

WARNING

Do not over speed PTO or machine breakage may result. Some

tractors are equipped with multispeed PTO ranges. Be certain

your tractor’s PTO is set for 540 rpm.

1. Park tractor and tiller on a level surface. Raise tiller to

align gearbox input shaft level with tractor PTO shaft.

Securely block tiller at this height to keep unit from

lowering while attaching the driveline.

2. Place gear selector in park, shut tractor engine off,

set park brake and remove switch key.

Refer to Figure 1-3 on page 11 for RTA12 or

Figure 1-5 on page 12 for RTR12

3. Remove gearbox shaft protector (#24) from end of

gearbox shaft and attach slip clutch end of

driveline (#25) to gearbox input shaft.

IMPORTANT: The driveline must be lubricated

before putting it into service. Refer to “Lubrication

Points” on page 25 for detailed instructions.

IMPORTANT: Drivelines with friction clutches must

go through a “run-in” operation prior to initial use

and after long periods of inactivity.See “Driveline

Protection” on page 22 for detailed instructions.

IMPORTANT: If tiller is to be used on more than one

tractor, an additional driveline may be required,

especially if a quick hitch is used.

IMPORTANT: The tractor’s PTO shaft and tiller

gearbox shaft must be aligned and level with each

other during installation of driveline. This alignment

is the shortest distance between the two shafts.

4. Attach other end of driveline to tractor PTO shaft.

5. Move driveline yokes back and forth to ensure both

ends are secured to the shafts. Reattach any yoke

that is loose.

6. Attach safety chain on the outer driveline shield to

the tractor frame to restrict outer shield from rotating.

Re-latch safety chain to outer driveline shield.

7. Attach safety chain on the inner driveline shield to

the tiller frame to restrict inner shield from rotating.

Re-latch safety chain to inner driveline shield.

Check Driveline Collapsible Length

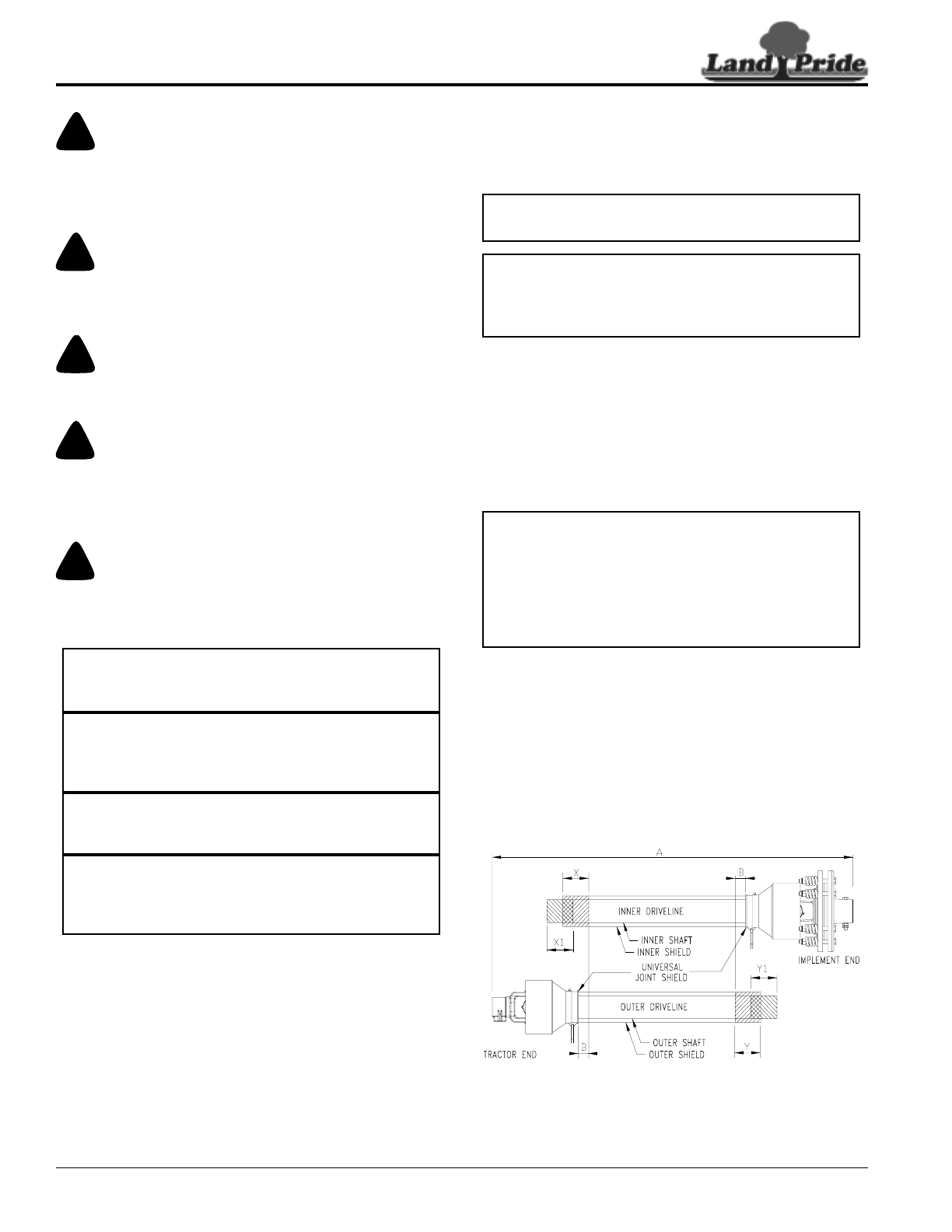

Refer to Figure 1-8:

1. Make sure driveline is installed properly before

checking driveline collapsed length (Refer to

“Driveline Installation” instructions on page 13).

2. With driveline level, measure 1" (“B” dimension)

back from universal joint shield to end of outer

driveline shield as shown in Figure 1-8.

a. If measurement is less than 1", shorten driveline.

a. If measurement is 1” or more, skip to “Check

Driveline Maximum Length” on page 15.

Driveline Shortening

Figure 1-8

NOTE: If driveline is too long to fit between tractor

and tiller, skip to “Shorten Driveline” on page 15.

IMPORTANT: Two safety chains are supplied with

the driveline. To keep driveline shields from rotating,

these chains must be attached to the outer and inner

driveline shields and to the tiller and tractor.

IMPORTANT: A driveline that is too long can bottom

out causing structural damage to tractor and tiller.

Always check driveline collapsed length during initial

setup, when connecting to a different tractor, and

when alternating between using a quick hitch and a

standard 3-point hitch. More than one driveline may

be required to fit all applications.

30563