11

Section 1 Assembly and Set-Up

12/14/01

RCR16 Series Rotary Cutters 312-742M

Land Pride

b. Pull driveline apart. Reattach outer sections to

tractor and gearbox. Pull on driveline section to be

sure that yoke locks into place.

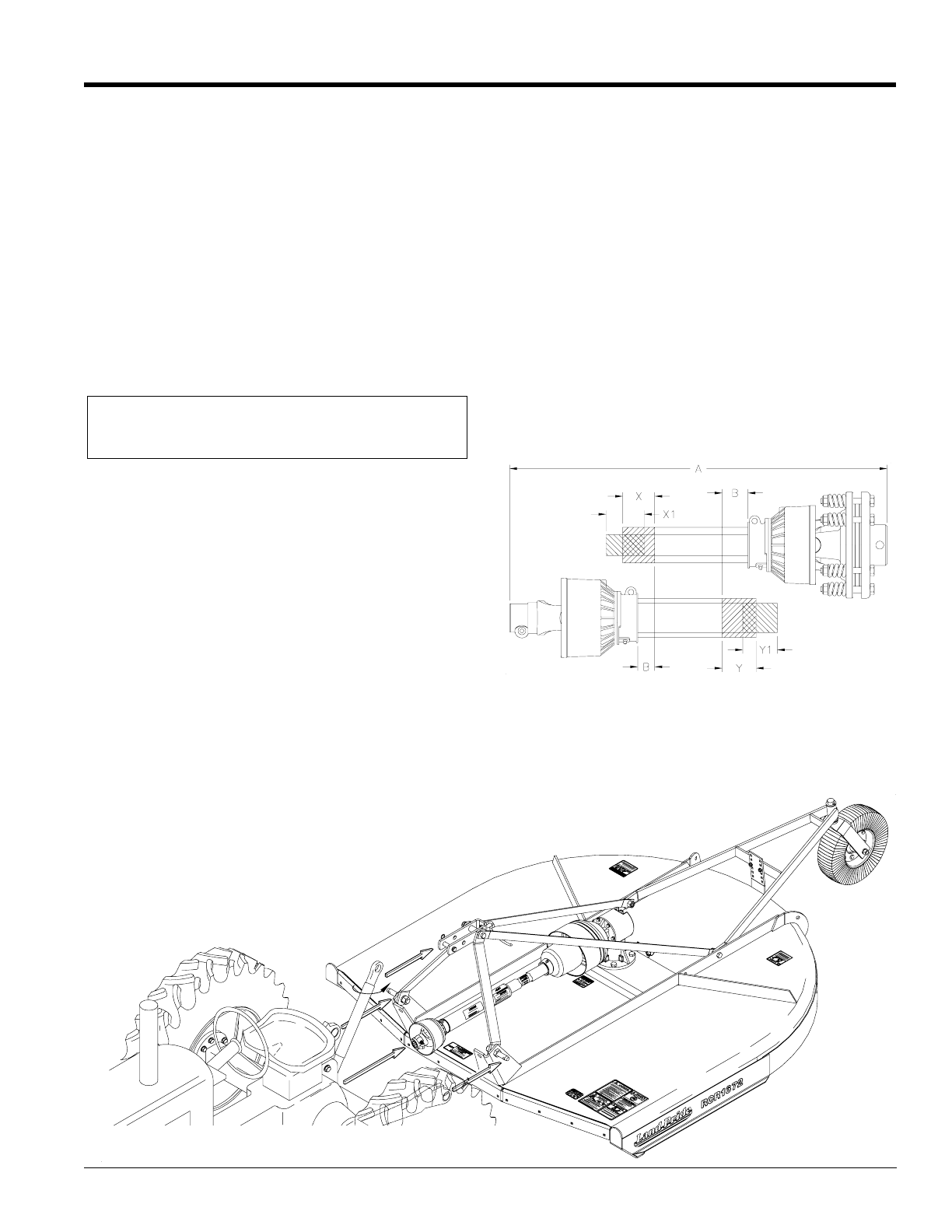

c. Hold driveline sections parallel to each other to

determine if too long. Each section should end

approximately 1" ("B" dimension) short of

reaching universal joint shield on opposite

section. If too long, measure 1" ("B" dimension)

back from universal joint shield and mark on

opposite section. Do this for both sections.

d. Cut off shield where marked ("X" dimension). Cut

shaft the same amount ("X" dimension).

e. Repeat the procedure to the other driveline half.

Remove all burrs and cuttings.

f. Apply multi-purpose grease to inside of outer

(female) driveline section. Assembledriveline and

install on tractor and cutter. Pull on each driveline

section to be sure yokes lock into place. Make

certain driveline shielding is in place and in good

condition.

Shortening Driveline Shafts

Figure 1-8

18347

Tractor Hook-Up

Figure 1-7

19747

Tractor Hook-Up

Refer to Figure 1-7:

1. Slowly back the tractor up to the cutter and use the

tractor’s 3-point hydraulic control to adjust the lower

link arms up or down to match the height of the cutter

hitch pins.

2. Simply position the lower link arms to "insert" the hitch

pin into the lower hitch link hole.

3. Install a linch pin or other fastener (supplied by

customer) through the hitch pin hole to lock the lower

links into position.

4. Connect the driveline to the tractor’s PTO output shaft

and secure with locking device on driveline. Connect

the safety chain to the hitch brace on the cutter to

restrict outer shield of driveline from rotating.

5. Connect the top link to the upper pivot hitch using the

3/4" clevis pin supplied. In most cases, the lowest hole

of the upper pivot hitch is the appropriate hole to use.

For tractors with shorter than normal top-links, the

second set of holes on the upper pivot hitch allows

greater ground clearance for the tailwheel.

6. Start the tractor and slowly engage the tractor’s

hydraulic 3-point to lift the cutter. Check for sufficient

drawbar clearance. Move the drawbar ahead, aside or

remove if required. Watch the telescoping movement

of the driveline to ensure that it does not bottom out

while lifting the 3-point. If the driveline does bottom

out, it will require shortening:

a. Refer to Figure 1-8. Raise the tractor 3-point hitch

so the input shaft of the cutter gearbox is in line

with the PTO shaft on the tractor. Shut down

tractor, leaving cutter in position of shortest

distance between shafts, refer to "A" dimension.

Securely block cutter in position. Remove

driveline from tractor and gearbox

NOTE: Chain should be attached at implement end

of driveline.