TP-6905 6/1452 Section 4 Scheduled Maintenance

4.3 Lubrication System

4.3.1 Oil Specifications

Use oil that displays the American Petroleum Institute

(API) Starburst certification mark FOR GASOLINE

ENGINES on the container. Do not use straight-weight

oils recommended for industrial or stationary engines.

CC or CD classification oils, even when labeled Heavy

Duty or For Natural Gas Engines are not acceptable.

Multi--viscosity synthetic oils are recommended. For

best performance in colder environments (such as the

United States and Canada), use Society of Automotive

Engineers (SAE) 5W-30, API service class SJor higher.

In extremely hot environments where temperatures are

never or rarely below

0_C(32_F), use a synthetic oil with

a viscosity designation of 10W-30, API service class SJ

or higher.

4.3.2 Oil Check

Check the oil level in the crankcase every 24 hours o f

operation or before the engine is started each day. Do

not check the oil level while operating the unit. Stop the

generator set and keep the generator set level to get an

accurate reading.

To check the oil level, remove the dipstick and wipe the

end clean. Reinsert the dipstick and wait at least 30

seconds. Remove the dipstick and check the level.

Maintainthe oil level betweenthe Full and Addmarks on

the dipstick, as shown in Figure 4-1. See Section 1,

Service Views for the dipstick location.

Note: Do not operate the set if the oil level is below the

Add mark or above the Full mark on the dipstick.

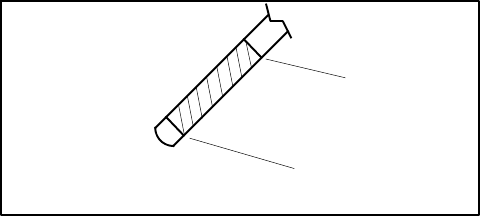

1

TP-5586-3

2

1. Full mark

2. Add mark

Figure 4-1 Oil Level Check

4.3.3 Oil Additions

Adding some oil between oil changes is normal. The

amount varies with generator set usage. Open the oil fill

cap and pour in a small amount of oil using a funnel or

other suitable pouring device. See Section 1, Service

Views, for the oil check and oil fill locations.

4.3.4 Oil and Filter Change

Change the oil yearly, after every 120 hours of use, or

before generator set storage. Change the oil more

frequently if the generator set operates under dirty,

dusty conditions. Change the oil while the engine is still

warm.See Section 1,Service Views,for oilfill, oil check,

and oil filter locations.

Dispose of all waste materials (engine oil, fuel, filter,

etc.) in an environmentally safe manner.

Note: Reset the maintenance timer on the RDC2

controller after changing the oil.

Oil Change Procedure

Whenever possible, drain the oil while it is still warm.

1. Drain the oil.

a. Press the OFF button on the RDC2 generator

set controller.

b. Disconnect the power for the battery charger.

c. Disconnect the generator set engine starting

battery, negative (--) lead first.

d. Remove the housing side panel.

e. Remove the plug from the oil drain fitting and

install a drain hose.

f. Open the oil drain valve on the engine.

g. Allowtime for the engine oilto drain completely.

h. Close the oil drain valve.

i. Replace the oil drain plug.