23English

MAINTENANCE

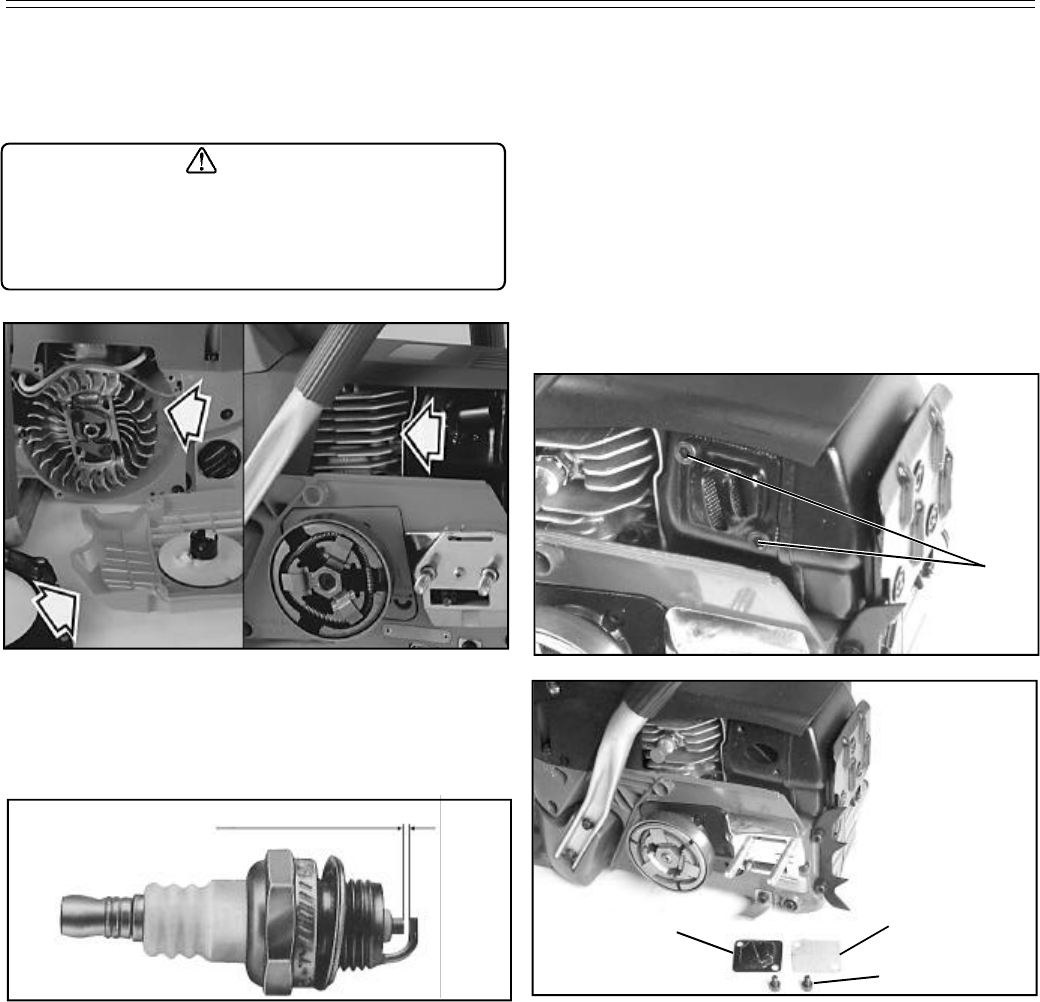

Spark Arresting Muffler

The muffler is equipped with a spark arrester screen. A faulty

spark arrester screen can create a fire hazard. Through normal

use the screen can become dirty and should be inspected

weekly and cleaned as required.

To clean:

• Allow the muffler to cool.

• Remove the two (2) deflector screws (A).

• Remove the deflector (B) and spark arrester (C).

• Clean and inspect the spark arrester screen. If the spark

arrester screen is damaged, faulty or deteriorated, replace the

screen.

• Reassemble components in reversed order of removal and

torque deflector screws to 43 in/lbs (4.9 Nm).

A

C

A

B

Spark Plug

This engine uses a Champion RCJ-7Y with .02 (0.5 mm) elec-

trode gap. Use an exact replacement and replace every six

months or more frequently, if necessary.

0.02" (0.5mm)

RCJ-7Y

Engine

Clean the cylinder & flywheel fins with compressed air or a brush

periodically. Dangerous overheating of engine may occur due to

impurities on the cylinder.

WARNING

Never run the saw without all the parts, including the

drivecase cover and starting housing, securely in place.

Because parts can fracture and pose a danger of thrown

objects, leave repairs to the flywheel and clutch to

trained John Deere Servicing Dealers.