Both the 135D and 225D feature fuel-effi cient diesel engines

that comply with the Tier 3 emission regulations, helping to

preserve the environment.

Welded bulkheads within the boom resist torsional stress.

Oil-impregnated bushings enhance durability and extend

grease intervals to 500 hours for the arm-and-boom joint

and 100 hours for the bucket joint.

Thicker reinforced idler bracket ensures maximum durability,

while preventing thrown tracks on rough terrain.

Reinforced resin thrust plates, grooved bushings, and

thermal-coated bucket joints increase arm and boom lube

intervals to 500 hours.

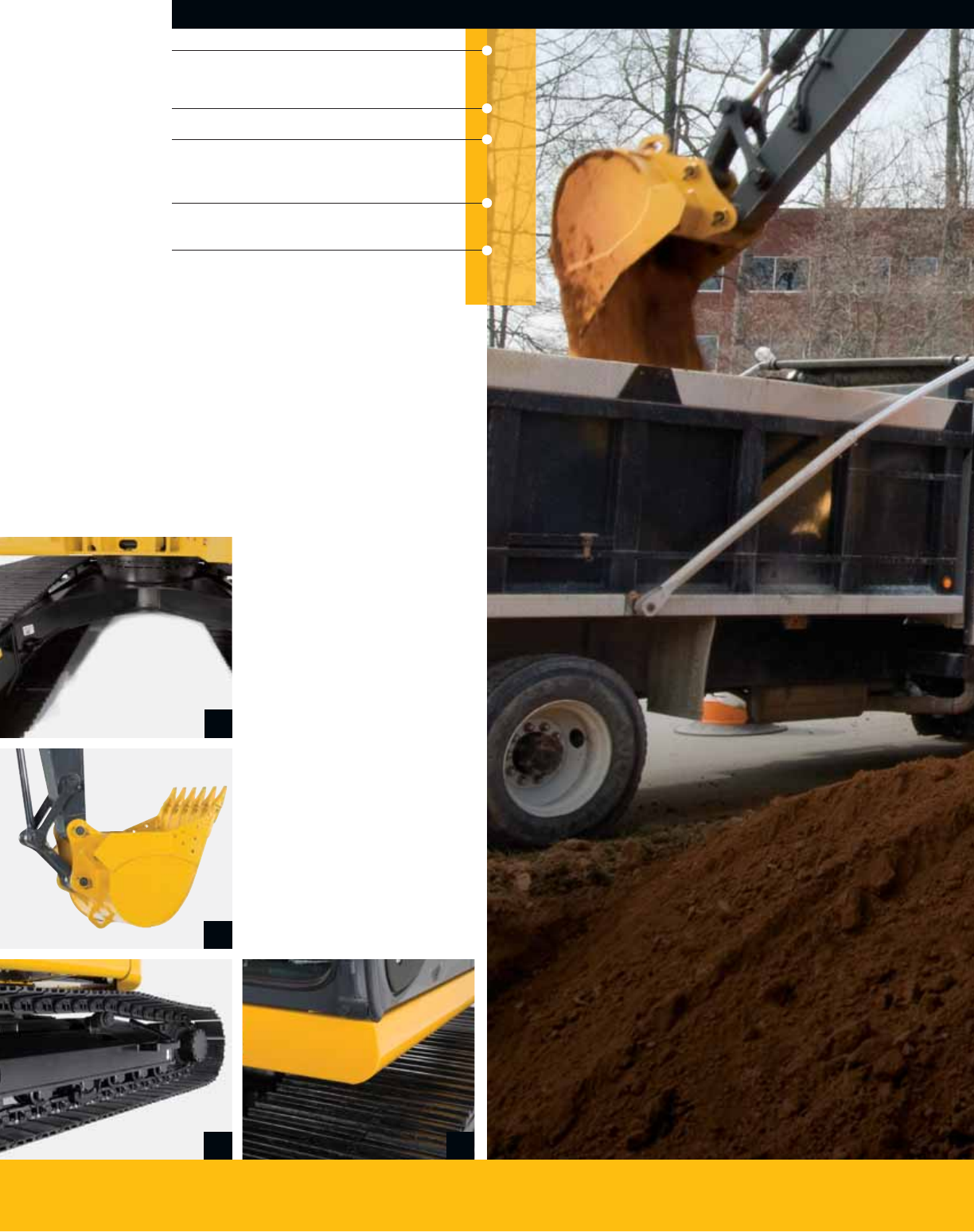

1. Box-section track frames, thick-plate

single-sheet mainframe, and large swing

bearing deliver rock-solid durability.

2. Tungsten-carbide coating on the

all-important bucket-to-arm joint

creates an extremely wear-resistant

surface that won’t compromise

joint strength.

3. With large idlers, rollers, and strutted

track links, the sealed and lubricated

undercarriage delivers long and reliable

performance.

4. Rigid, reinforced D-channel side frames

resist impact, providing maximum cab

and component protection.

2

3

1

4

Vertis QCA

1300 19th Street, Suite 200

East Moline, IL 61244

Cyan

Magenta

Yellow Black

DKAX135D225D Page 8 DK