109631_0908 4-5

6. Keep oil and grease away from belts.

7. When replacing belts, check pulley groove condition. A worn groove

(notch in shoulder) will cause rapid belt failure. Replace pulley if

groove is worn.

8. Never pry belt over edge of pulley, this may cause fibers of belt to break.

9. Sun and weather injure belts, unnecessary exposure to these elements

should be avoided whenever possible.

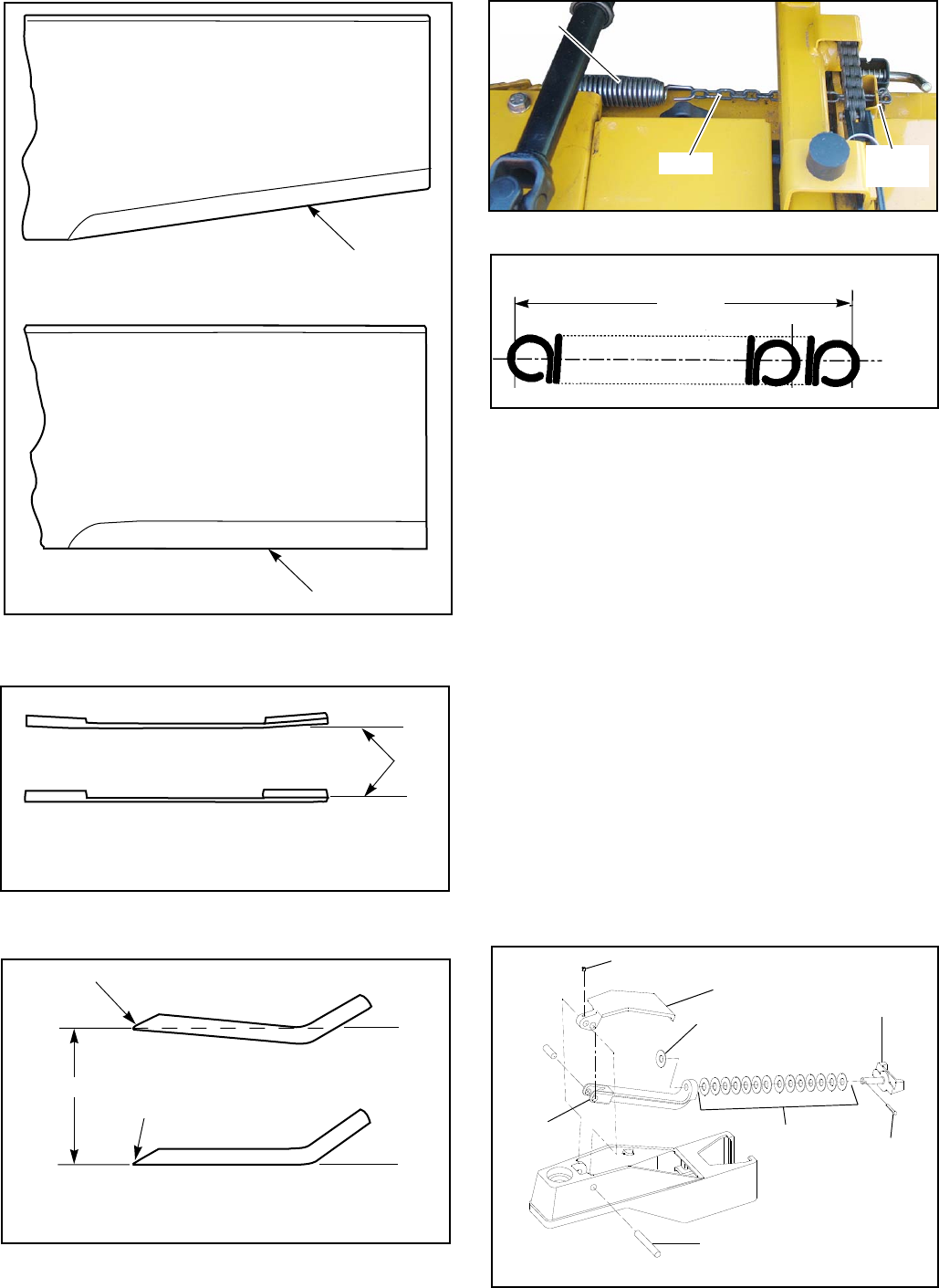

Gauge wheel tension adjustment

Gauge wheel arms are held in place against the gauge wheel arm mount

by lock linkage and lock pin. Tension on arms is controlled by spring wash-

ers. There are 15 washers on each arm: 14 are between the lock linkage and

lock pin and 1 is a spare, placed in front of the lock linkage as shown in Fig.

4-12.

NOTE: Seven of the spring washers are turned one way and the other

seven are reversed. The concave part of the two sets of washers should face

each other. This is what provides the tension. Fig. 7-13

If gauge wheels do not stay firmly in place when handle is in down

(closed) position:

1. Relieve tension on lock pin and linkage by removing handle, lock link-

age and lock pin from gauge wheel arm assembly.

2. Remove cotter pin from lock pin and insert one or two spare washers

between lock linkage and lock pin.

3. Reassemble gauge wheel arm by reversing above directions.

NOTE: If more tension is needed, additional spring washers may be

purchased from your Hustler Dealer.

Handle pin

Set screw

Handle

Lock pin

Spring

Lock

Spare spring washer

Cotter pin

linkage

washers

Spring Extension

8.1 - 9.1”

Fig. 4-10

Fig. 4-11

Spring

Chain

Anchor

bracket

Cutting Edge

Cutting Plane

Cutting Edge

Twisted Blade Edge (Replace)

Straight Blade Edge

End view of blades, comparing twisted and straightened blades.

Fig. 4-9

Warped Blade (Replace)

Straight Edge

Comparison of Warped and Straight Blades

Cutting

Plane

Fig. 4-8

Do not sharpen to original pattern (below)

It is easier to get a straight cutting edge following

the resharpening pattern shown above.

Resharpening

Pattern

Original Edge

Figure 4-7

Fig. 4-12