open flame or spark and store machine away

from open flame or spark if there is fuel in the

tank. Read and observe safety precautions at

front of this manual.

The 11 U.S. gallon (41.6 liter) fuel tank is located in the

tractor’s right fender. It is equipped with a gauge built into

the filler cap.

There is a fuel shut-off valve installed on the fuel tank.

Close this valve to prevent fuel loss or spill whenever

changing filter, performing maintenance, transporting or

storing the tractor.

Models 4200, 4400, 4420 and 4600: This engine requires

number 2 diesel fuel only. The spin-on type fuel filter is

located on the left, rear side of the engine. Change filter

after every 400 hours of operation or annually, whichever

occurs first.

Diesel engines are subject to air blockage whenever the

fuel tank runs empty, the fuel filter has been removed, any

fuel lines have been disconnected or removed and replaced,

or when the tractor has been stored for a period of time.

Should such air blockage occur, it will be necessary to bleed

the system, removing any trapped air between the fuel tank

and filter, then trapped air between the filter and injector

pump as follows:

1. Fill the tank with fresh fuel and make sure the shut-off

valve is open at tank.

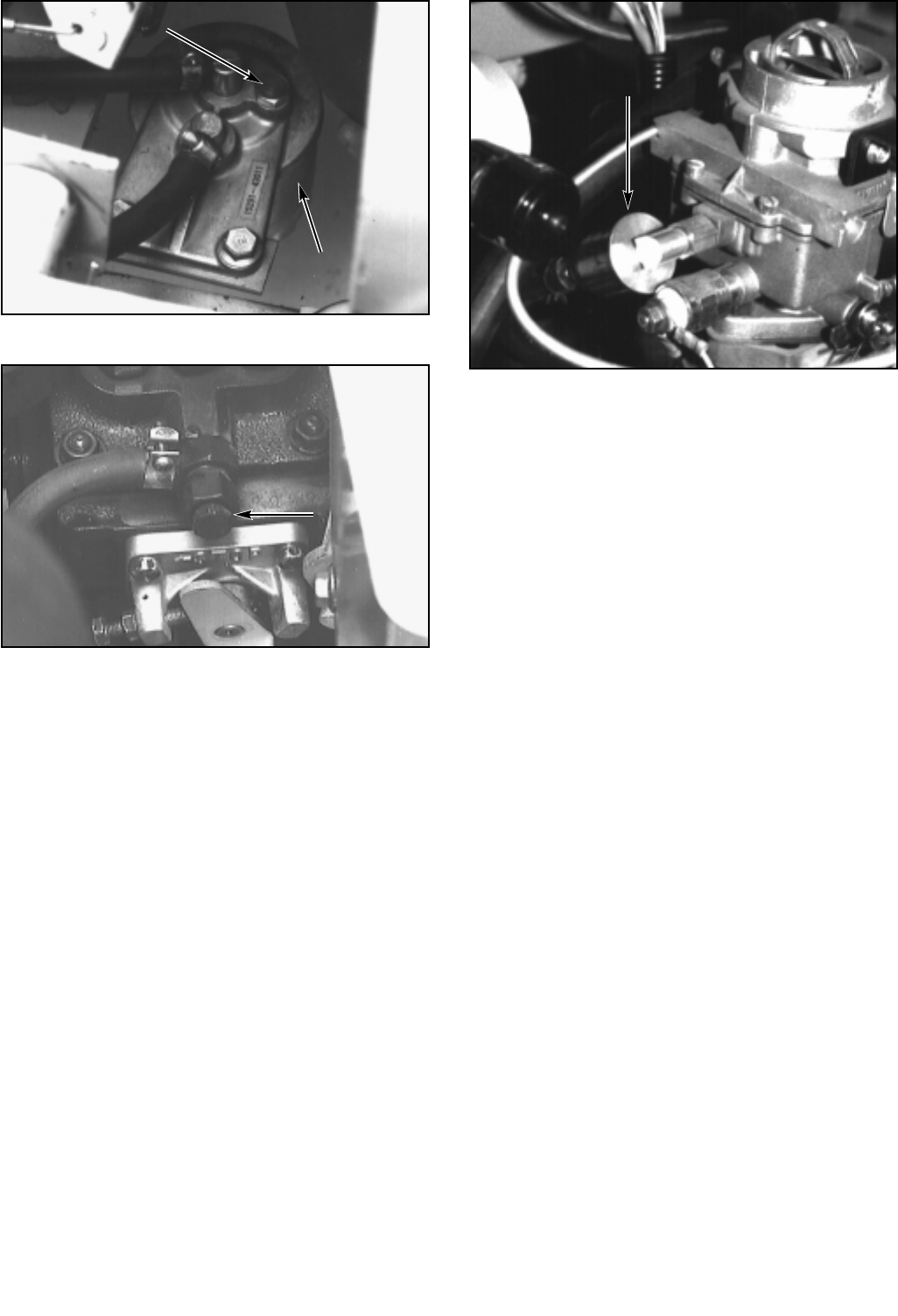

2. Loosen the vent screw (Fig. 5-13) located on top of the

fuel filter and leave it open until air bubbles are no

longer present, then close the vent screw.

3. Loosen the vent screw on the injector pump (Fig. 5-

14). Operate the hand priming lever (located below

the injector pump) 10 to 30 times.

4. Start the engine and run at low rpm for 15 to 30

seconds to expel air from pump, then close the air vent

screw.

5. If engine fails to start, repeat steps 2, 3 and 4.

Models 4300 and 4500: This engine is designed to use

unleaded gasoline with a minimum octane rating of 87. See

engine manual for exceptions.

The fuel filter is located on the left side of the carburetor

(Fig. 5-15). Change filter every 400 hours or annually,

whichever occurs first. When changing filter, by sure to

note direction of fuel flow marked on filter case.

When replacing the fuel filter, check the fuel line hoses

for any cracks or leaks. Replace as needed.

Engine oil and filter

Check engine oil daily and after every 4 hours of

operation. Tractor must be setting level when checking oil.

Refer to engine manual and maintenance schedule for oil

recommendation and capacities.

Engine air filter

A specially designed two-stage dry filter, with restriction

indicator (Fig. 5-16), supplies clean combustion air to the

engine. This is a self-cleaning element, but it needs to be

replaced whenever the restriction indicator shows red.

Check the indicator daily and replace element as needed or

annually whichever occurs first.

Recommended service procedure

Many engine failures can be attributed to improper air

cleaner servicing. Ingested dust and dirt will cause cylinder,

piston and bearing damage in a few hours. “Dusted”

engines will result from:

1. Overservicing the air filter element.

2. Improper installation.

728444 Rev. 11/02

5-13

Figure 5-15

FFuueell FFiilltteerr

((44330000 && 44550000))

Figure 5-13

VVeenntt

SSccrreeww

FFuueell FFiilltteerr

AAsssseemmbbllyy

Figure 5-14

VVeenntt

SSccrreeww