8 – English

SAFETY INSTRUCTIONS

Sharpening your chain and

adjusting raker clearance

WARNING!

The risk of kickback is increased with a

badly sharpened chain!

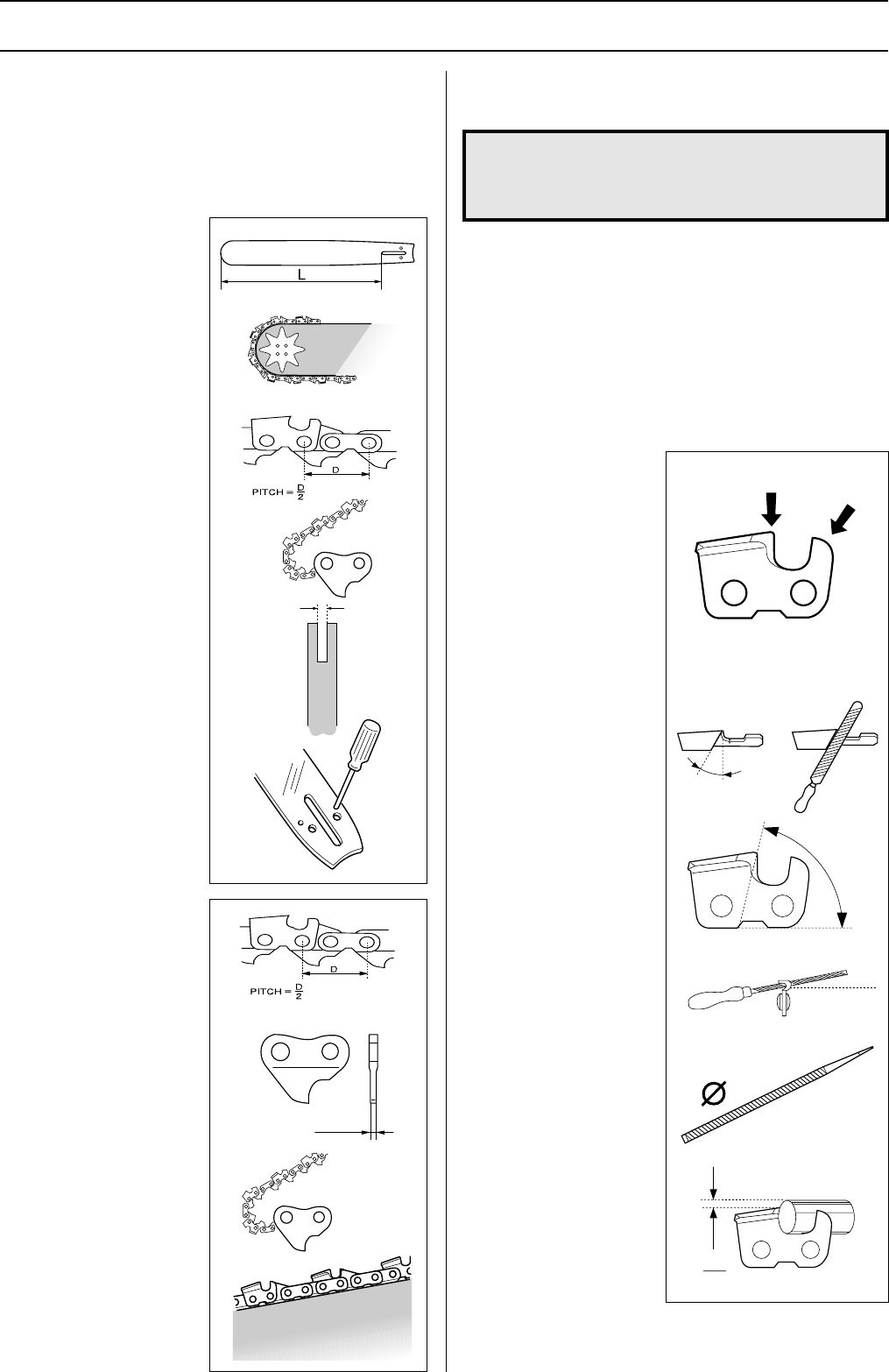

Specification of blade and chain

When the cutting equipment supplied with your saw

becomes worn or damaged you will need to replace it. Use

only the type of bar and chain recommended by us.

A. General information on sharpening

cutting teeth

• Never use a blunt chain. When the chain is blunt you have

to exert more pressure to force the bar through the wood

and the cuttings will be very small. If the chain is very blunt

it will not produce any cuttings at all, just wood powder.

• A sharp chain eats its way through the wood and produces

long, thick cuttings.

• The cutting part of the

chain is called the

CUTTING LINK and

this consists of a

CUTTING TOOTH

(A) and the RAKER LIP

(B). The cutting depth is

determined by the

difference in height

between the two.

• When you sharpen a

cutting tooth there are

five important

factors to remember:

FILING ANGLE

CUTTING ANGLE

FILE POSITION

ROUND FILE DIA-

METER

FILE DEPTH

Guide bar

• Length (inches/cm)

• Number of teeth on bar

tip sprocket (T).

Small number = small tip

radius = low-kickback

• Chain pitch (inches)

The spacing between the

drive links of the chain

must match the spacing of

the teeth on the bar tip

sprocket and drive

sprocket.

• Number of drive links

The number of drive links

is determined by the

length of the bar, the

chain pitch and the

number of teeth on the

bar tip sprocket.

• Bar groove width (inches/

mm)

The groove in the bar

must match the width of

the chain drive links.

• Saw chain oil hole and

hole for chain tensioner

The bar must be matched

to the chain saw design.

!

B

A

1

5

Saw chain

• Saw chain pitch (inches)

Spacing between drive

links.

• Drive link width (mm/

inches)

• Number of drive links

• Level of kickbak

reduction

The level of kickback

reduction offered by a

chain is indicated by its

model number.