10 – English

SAFETY INSTRUCTIONS

D. Correction of raker clearance

Chain lubrication

WARNING!

A slack chain may jump off and cause

serious or even fatal injury.

A. Checking

• Check the chain

lubrication each time the

petrol is replenished.

Aim the tip of the saw at a

light coloured surface

about 20 cm away. After 1

minute running at 3/4

throttle you should see a

distinct line of oil on the

light surface.

The oil flow can be

regulated with the screw

(A) on the hydraulic

motor.

Turn the screw anti-

clockwise to increase the

flow.

• The more you use a

chain the longer it

becomes. It is therefore

important to adjust the

chain regularly to take

up the slack.

• Check the chain tension

every time you refuel.

NOTE! A new saw chain

has a running-in period

during which you should

check the tension more

frequently.

• Tension the chain as

tightly as possible, but

not so tight that you

cannot pull it round

freely by hand.

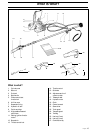

Tensioning the saw chain

• When correction of the

raker clearance is made

the teeth must be newly

sharpened.

We recommend that you

adjust the raker clearance

every third time you

sharpen the chain.

NOTE! This

recommendation

assumes that the length

of the cutting teeth is not

reduced excessively.

• A FLAT FILE and an

RAKER CLEARANCE

GAUGE are required to

correct the raker

clearance.

• Place the gauge over the

raker lip.

• Place the file over the

part of the lip that

protrudes through the

gauge and file off the

excess. The clearance is

correct when you no

longer feel any resistance

as you draw the file over

the gauge.

!

A

1. Release the two nuts.

2. Adjust the chain tension by

turning the chain

tensioning screw.

3. Tighten both nuts.