English – 21

MAINTENANCE

Air filter

The air filters must be regularly cleaned from dust and dirt in

order to avoid:

• Carburettor malfunctions

• Starting problems

• Engine power reduction

• Unnecessary wear on the engine parts

• Abnormal fuel consumption

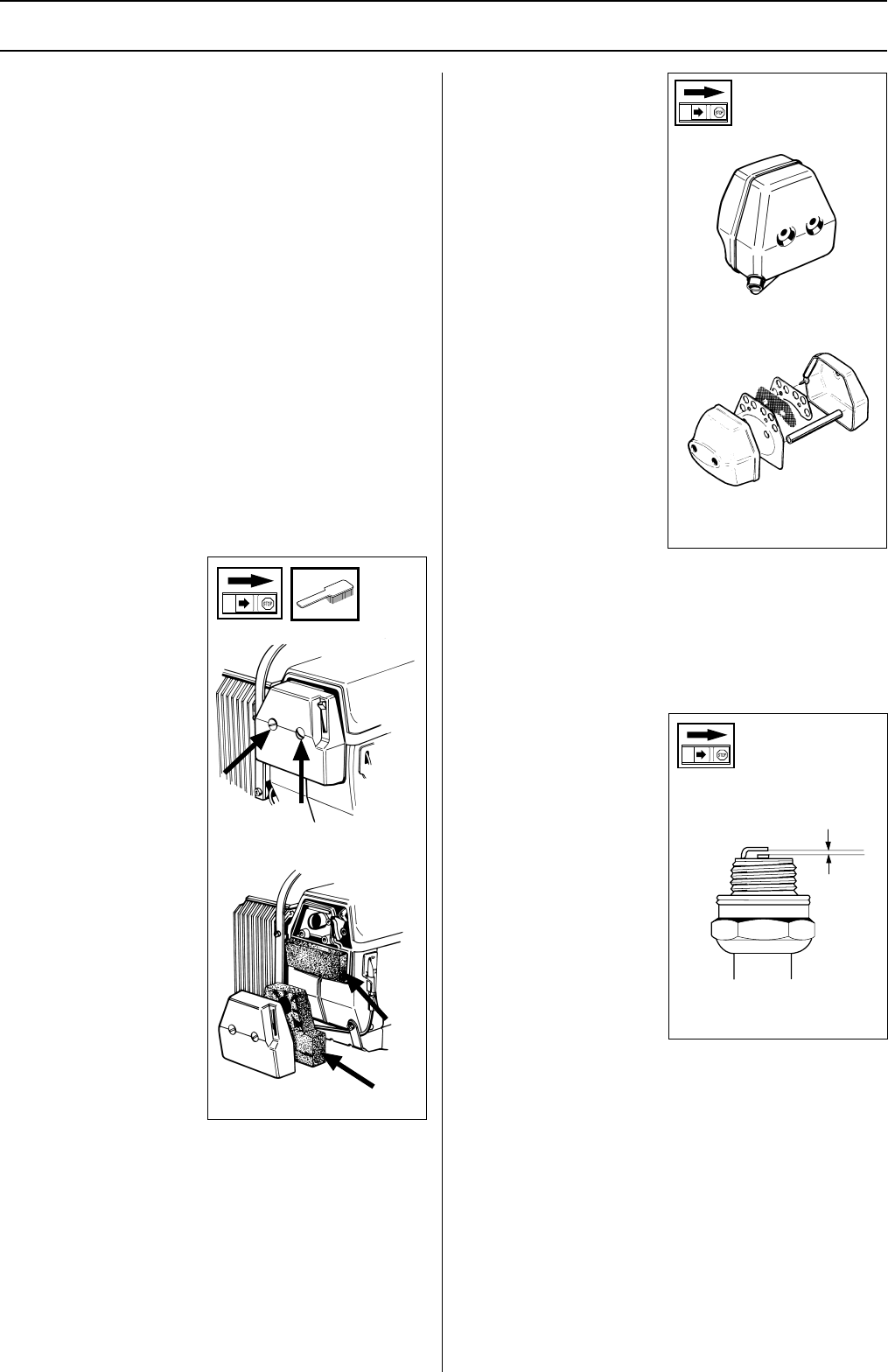

If the engine is low on power, difficult to start or runs

poorly at idling speed, always check the spark plug first.

If the spark plug is dirty, clean it and check the electrode gap.

Readjust if necessary. The correct gap is 0.5 mm (.020"). The

spark plug should be replaced after about one month or

earlier if the electrodes are badly eroded.

IMPORTANT!

Always use the recommended spark plug type. Wrong type

may ruin the piston/cylinder.

Spark plug

The spark plug condition is

influenced by:

• An incorrect carburettor

setting.

• An incorrect fuel mixture

(too much or faulty oil).

• A dirty air filter.

These factors cause deposits

on the spark plug

electrodes, which may result

in malfunction and starting

difficulties.

Muffler

The muffler is designed in

order to reduce the noise

level and to direct the

exhaust gases away from the

operator. The exhaust gases

are hot and can contain

sparks, which may cause fire

if directed against dry and

combustible material.

Some mufflers are equipped

with a special screen. If your

saw has this type of muffler,

you should clean the screen

at least once a week. This is

done with a wire brush. The

screen must be replaced, if

damaged. The engine will

be overheated, if the screen

is clogged. This results in

damage on the cylinder and

the piston.

CAUTION!

Never use a pruner with a

clogged or defective muffler.

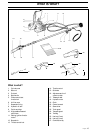

Cleaning/change

Clean the filter after 25

hours or more regularly if

operating conditions are

exceptionally dusty.

Dismantle the air filter

cover and remove the air

filters. Wash in clean, warm

soapy water.

Ensure that the filters are

dry before refitting.

An air filter used for a long

period of time can never be

cleaned completely.

Therefore it is necessary to

replace the filter from time

to time with a new filter.

A damaged air filter must

always be replaced.

Correctly adjusted carburettor

A correctly adjusted carburettor implies that the engine

accelerates without a pause and that the engine splutters

slightly at full throttle. Also, the chain does not rotate at

idling speed. An excessively lean setting for the L-nozzle can

result in starting difficulties and poor acceleration. An

excessively lean H-nozzle setting results in a lower output,

poor acceleration, and/or damage to the engine.

An over rich setting of both L and H results in acceleration

problems or excessively low working revs.

0,5 mm