18 – English

FUEL HANDLING – START AND STOP

Start and stop

• Clean around the fuel cap.

Contamination in the

tank can disrupt opera-

tions.

• Ensure that the fuel is well

mixed by shaking the

container before filling the

tank.

Cold engine

IGNITION:

Set the stop switch in start

position.

CHOKE:

Set the choke lever in the

choke position.

Varm engine

Use the same procedure as

for the cold engine but do

not set the choke lever in

the choke position.

Start throttle is obtained by

first moving the choke lever

to the choke position and

then back to the initial

position.

Stop

The engine is stopped by

switching the ignition off.

NOTE!

Never start the engine

without replenishing the

hydraulic oil and with the

hydraulic hoses fitted.

Running the engine without

hydraulic oil and without

the hoses fitted can result in

malfunction to the hydraulic

system.

WARNING!

• Always move the machine from the place

of filling before starting.

• Place the machine on a solid surface.

Check that you stand steady when

starting the engine.

• Make sure no unauthorized persons are

within the working area.

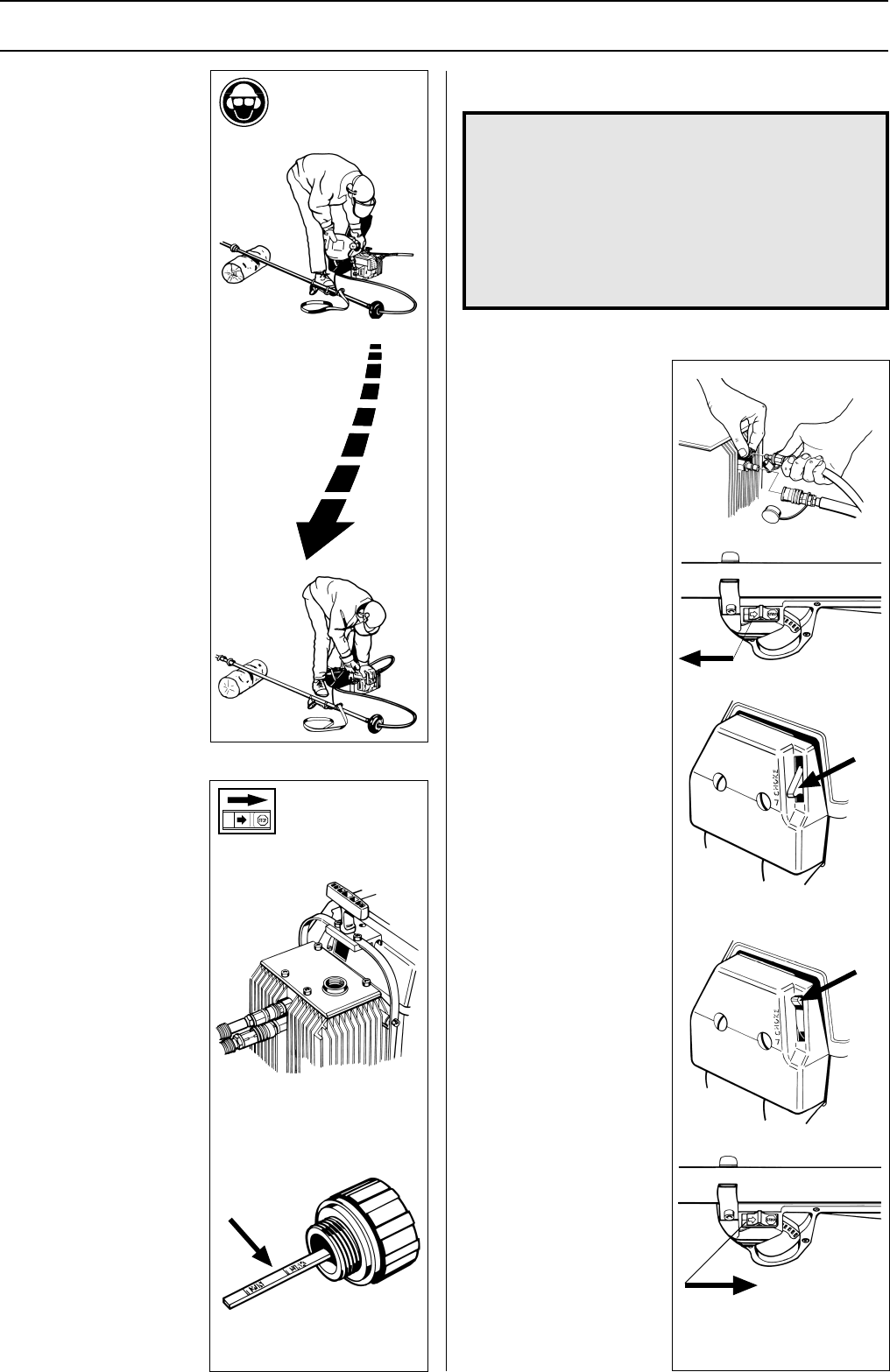

Hydraulic oil

ISO VG 32 hydraulic oil is

recommended where the air

temperature is below 20ºC.

ISO VG 45 hydraulic oil is

recommended if the air

temperature is above 20ºC.

We also recommend any

equivalent grade of approved

biodegradable hydraulic oil.

CAUTION!

The oil’s flash point must be

greater than +160°C. Fill

the hydraulic oil until its

level is visible in the sight-

glass. Check the level of the

hydraulic oil each time you

refuel.

Fill with hydraulic oil until

the level lies between the

”Min” and ”Max” markings

on the oil stick. Screw down

the tank cap completely after

each check.

!