17

11. SELECTING FUELS

FOR STANDBY

DEPENDABILITY

The types of fuels available for diesel engines, vary

from highly volatile jet fuels and kerosene to the

heavier fuel oils. Most diesel engines are capable

of burning a wide range of fuels within these

extremes. The following information will assist you

in selecting the type of fuel that will afford the best

overall performance and reliability of your

Generating Set.

11.1 Types Of Fuel Oil

The quality of fuel oil can be a dominant factor in

satisfactory engine life and performance. A large

variety of fuel oils are marketed for diesel engine

use. Their properties depend upon the refining

practices employed and the nature of the crude oils

from which they are produced. For example, fuel

oils may be produced within the boiling range of

148 to 371°C (300 to 700°F), having many possible

combinations of other properties.

The additional contaminants present in low grade

fuels may result in darker exhaust and more

pronounced odour. This may be objectionable in

hospitals, offices commercial and urban locations.

Thus, location, application and environmental

conditions should be considered when selecting

fuel.

The Generating Set owner may elect to use a low

grade fuel because high-grade fuels are not readily

available in his area or because he can realise a net

saving with low grade fuels despite higher engine

maintenance costs. In that case, frequent

examination of lubrication oil should be made to

determine sludge formation and the extent of lube

oil contamination.

Aside from the various grades of fuel oil commonly

used in diesel engines, aircraft jet fuels also are

sometimes used, especially in circumstances where

the jet fuels are more readily available than

conventional fuels. Jet fuels are lower in B.T.U.

content and lubrication quality than conventional

fuels. As a result, some diesel fuel systems must

undergo major modifications to accommodate this

type of fuel. For use of jet fuel please consult FG

Wilson.

Reliable operation of diesel engines may vary from

one fuel to another, depending on many factors,

including fuel characteristics and engine operating

conditions.

The fuels commonly known as high-grade fuels

seldom contribute to the formation of harmful

engine deposits and corrosion. On the other hand,

while refining improves the fuel, it also lowers the

B.T.U. or heat value of the fuel. As a result, the

higher grade fuels develop slightly less power than

the same quantity of low grade fuel. This is

usually more than offset by the advantages of high

grade fuels such as quicker starts and less frequent

overhauls. Before using low-grade fuels, therefore,

some understanding of the problems and extra

costs that may be encountered is necessary.

Fuels with high sulphur content cause corrosion,

wear and deposits in the engine. Fuels that are not

volatile enough or don't ignite rapidly may leave

harmful deposits in the engine and may cause poor

starting or running under adverse operating

conditions. The use of low grade fuels may require

the use of high priced, higher detergent lubricating

oils and more frequent oil changes.

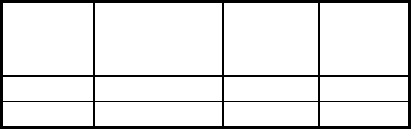

11.2 Fuel Selection Guide

Specify fuel properties according to the following

chart.

Final

Boiling

Point

Cetane

Number

(Min)

Sulphur

Number

(Max)

Winter 290°C (550ºF) 45 0.5 %

Summer 315°C (600ºF) 40 0.5 %

Selecting a fuel that keeps within these

specifications will tend to reduce the possibility of

harmful deposits and corrosion in the engine, both

of which could result in more frequent overhauls

and greater maintenance expense. Specify exact

fuel properties to your local fuel supplier.

11.3 Maintaining Fresh Fuel

Most fuels deteriorate if they stand unused for a

period of many months. With standby generators it

is preferable to store only enough fuel to support a

few days or even only eight hours of continuous

running of the Generating Set so that normal engine

testing will turn over a tank full within a year and a

half.