13

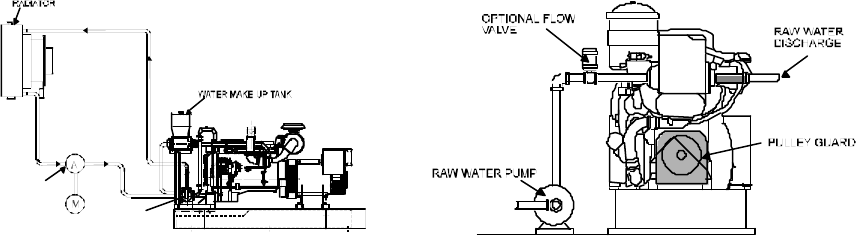

FIG 9.4 TYPICAL HEAT EXCHANGER INSTALLATION FIG 9.5 HEAT EXCHANGER COOLING SYSTEM

9.5 Antifreeze Protection

If the engine is to be exposed to low temperatures,

the cooling water in the engine must be protected

from freezing. In radiator-cooled installations,

antifreeze may be added to the water to prevent

freezing. Ethylene glycol permanent antifreeze is

recommended for diesel engines. It includes its

own corrosion inhibitor, which eventually may have

to be replenished. Only a non-chromate inhibitor

should be used with ethylene glycol.

The proportion of ethylene glycol required is

dictated primarily by the need for protection against

freezing in the lowest ambient air temperature that

will be encountered. The concentration of ethylene

glycol must be at least 30% to afford adequate

corrosion protection. The concentration must not

exceed 67% to maintain adequate heat transfer

capability.

For heat exchanger cooling, antifreeze does only

half the job since it can only be used in the engine

water side of the heat exchanger. There must be

assurance that the raw water source will not freeze.

9.6 Water Conditioning

Soft water should always be used in the engine

whether cooling is by radiator or by heat exchanger

Adding a commercial softener is the easiest and

most economical method of water softening. Your

FG Wilson Distributor can recommend suitable

softeners. Manufacturers instructions should be

carefully followed.

10. FUEL SUPPLY

A dependable fuel supply system must assure

instant availability of fuel to facilitate starting and

to keep the engine operating. This requires, at a

minimum, a small day tank (usually incorporated

into the generating set baseframe - called a

basetank) located close to the set. With generally

only a capacity of 8 hours operation, this day tank

is often backed up by an auxiliary remote fuel

system including a bulk storage tank and the

associated pumps and plumbing. Extended

capacity basetanks are also generally available for

longer operation prior to refuelling. Especially for

standby generating sets it not advisable to depend

on regular delivery of fuel. The emergency that

requires use of the standby set may also interrupt

the delivery of fuel.

10.1 Fuel Tank Location

The day tank should be located as close to the

generating set as possible. Normally it is safe to

store diesel fuel in the same room with the

generating set because there is less danger of fire or

fumes with diesel than with petrol (gasoline). Thus,

if building codes and fire regulations permit, the day

tank should be located in the base of the generating

set, along side the set, or in an adjacent room.

Where an remote fuel system is to be installed with

a bulk storage tank, the bulk tank may be located

outside the building where it will be convenient for

refilling, cleaning and inspection. It should not,

however, be exposed to freezing weather because

fuel flow will be restricted as viscosity increases

with cold temperature. The tank may be located

either above or below ground level.

AUXILIARY PUMP

HEAT

EXCHANGER