7

6.2 Exhaust Pipe Flexible Section

A flexible connection between the manifold and the

exhaust piping system should be used to prevent

transmitting engine vibration to the piping and the

building, and to isolate the engine and piping from

forces due to thermal expansion, motion or weight

of piping. A well designed flex section will permit

operation with ± 13 mm (0.5 in) permanent

displacement in any direction of either end of the

section without damage. Not only must the section

have the flexibility to compensate for a nominal

amount of permanent mismatch between piping and

manifold, but it must also yield readily to

intermittent motion of the Generating Set on its

vibration isolators in response to load changes.

The flexible connector should be specified with the

Generating Set.

6.3 Exhaust Pipe Insulation

No exposed parts of the exhaust system should be

near wood or other inflammable material. Exhaust

piping inside the building (and the silencer if

mounted inside) should be covered with suitable

insulation materials to protect personnel and to

reduce room temperature. A sufficient layer of

suitable insulating material surrounding the piping

and silencer and retained by a stainless steel or

aluminium sheath may substantially reduce heat

radiation to the room from the exhaust system.

An additional benefit of the insulation is that it

provides sound attenuation to reduce noise in the

room.

6.4 Minimising Exhaust Flow

Restriction

Free flow of exhaust gases through the pipe is

essential to minimise exhaust back pressure.

Excessive exhaust back pressure seriously affects

engine horsepower output, durability and fuel

consumption. Restricting the discharge of gases

from the cylinder causes poor combustion and

higher operating temperatures. The major design

factors that may cause high back pressure are:

• Exhaust pipe diameter too small

• Exhaust pipe too long

• Too many sharp bends in exhaust system

• Exhaust silencer restriction too high

• At certain critical lengths, standing pressure

waves may cause high back pressure

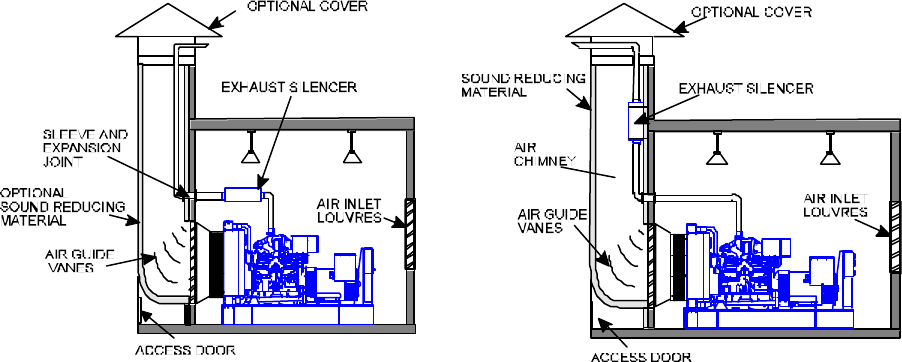

FIG 6.2 HORIZONTALLY MOUNTED EXHAUST SILENCER FIG 6.3 RADIATOR AIR DISCHARGING INTO

WITH EXHAUST PIPE AND RADIATOR AIR SOUND-INSULATED STACK CONTAINING

UTILISING COMMON STACK EXHAUST SILENCER