3.3.6 REPLACING THE SPARK PLUG

Use Champion RC14YC spark plug or equivalent. The correct air gap

is 1.01 mm (0.040 in.) (Figure 18). Replace the plug once each year.

This will help the engine start easier and run better.

1. Stop the engine and pull the spark plug wire off of the spark

plug.

2. Clean the area around the spark plug and remove it from the

cylinder head.

3. Set the spark plug's gap to 1.01 mm (0.040 in.). Install the

correctly gapped spark plug into the cylinder head.

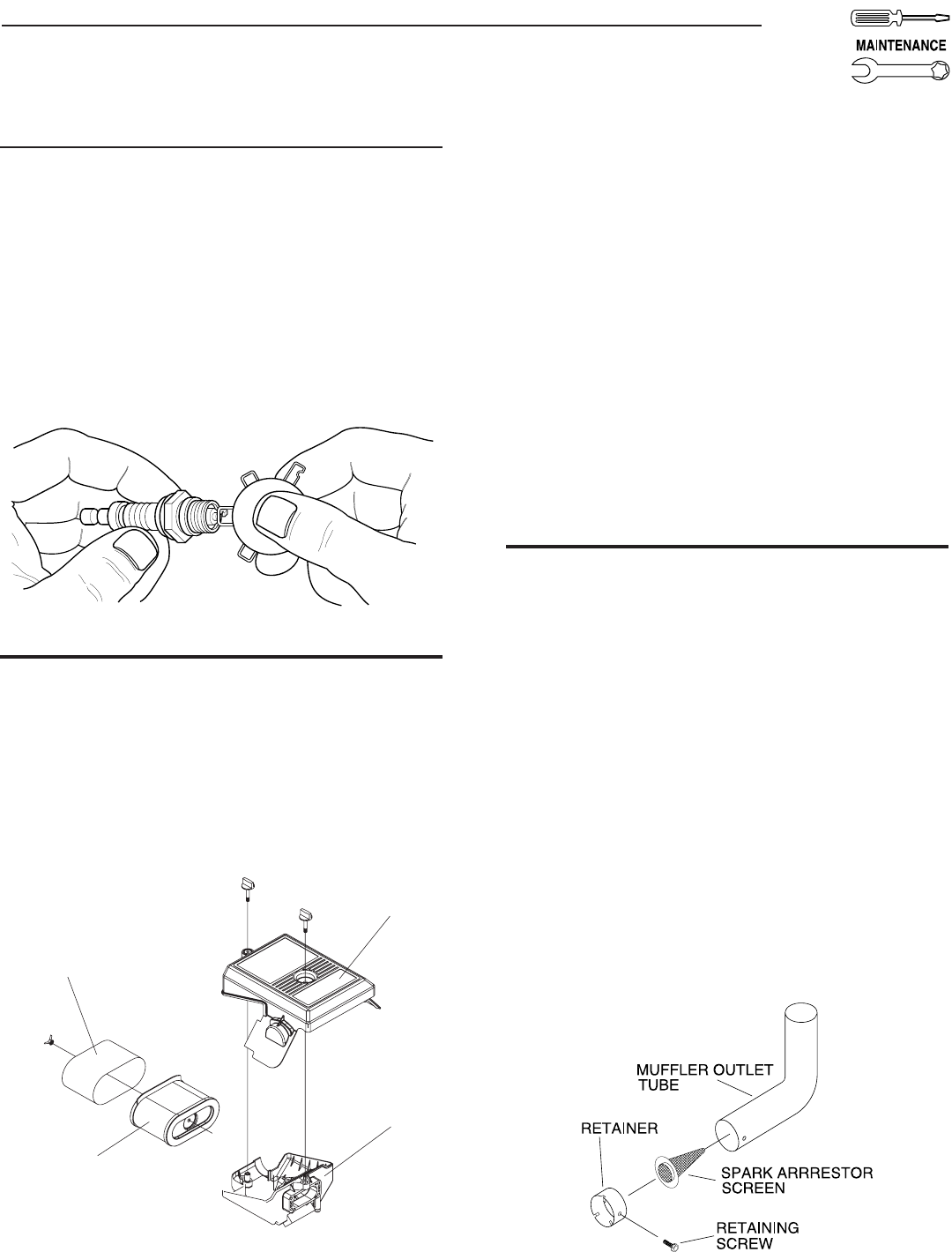

Figure 18 - Spark Plug Gap

3.4 SERVICE AIR CLEANER

The engine will not run properly and may be damaged if using a dirty

air cleaner. Clean or replace the air cleaner paper filter once a year

(Figure 19). Clean or replace more often if operating under dusty

conditions. Clean foam pre-cleaner every month or more often under

dusty conditions.

Figure 19 - Air Cleaner

Pre-Cleaner

Filter

Cover

Base

To clean or replace foam pre-cleaner:

Remove air cleaner cover, then foam pre-filter.

Wash pre-cleaner in soapy water. Squeeze pre-filter dry in clean

cloth (DO NOT TWIST).

Clean air cleaner cover before re-installing it.

To clean or replace paper air filter:

Remove air cleaner cover; then remove foam pre-filter (service if

necessary) and remove paper filter.

Clean paper filter by tapping it gently on a solid surface. If the

filter is too dirty, replace it with a new one. Dispose of the old filter

properly.

Clean air cleaner cover then slip pre-cleaner over filter. Next insert

new paper filter into the base of the air cleaner. Re-install air

cleaner cover.

NOTE:

To order a new air filter, please contact the nearest authorized

service center at 1-800-333-1322.

3.5 CLEAN SPARK ARRESTOR SCREEN

The engine exhaust muffler has a spark arrestor screen. Inspect and

clean the screen at least once each year (Figure 20). If unit is used

regularly, inspect and clean more often.

NOTE:

If using the generator on any forest-covered, brush-covered

or grass-covered unimproved land, it must equipped with a

spark arrestor. The spark arrestor must be maintained in good

condition by the owner/operator.

Clean and inspect the spark arrestor as follows:

Remove the screen retaining bracket by removing the screw.

Slide the spark arrestor screen out from the tail pipe.

Inspect screen and replace if torn, perforated or otherwise

damaged. DO NOT USE a defective screen. If screen is not

damaged, clean it with commercial solvent.

Replace the screen and the retaining bracket.

Figure 20 - Spark Arrestor

•

•

•

•

•

•

•

•

•

•

Section 3 — Maintenance

Portable Generator System

15