27

replaced. If the flow drop is less than 1 GPM you

will need to replace the wheel motor.

REPLACING THE HYDRAULIC PUMP

The two hydraulic pumps are located inside the chassis

in front of the engine. The pumps are maintenance free

and should be replaced in the event of a failure. See

Figure 18.

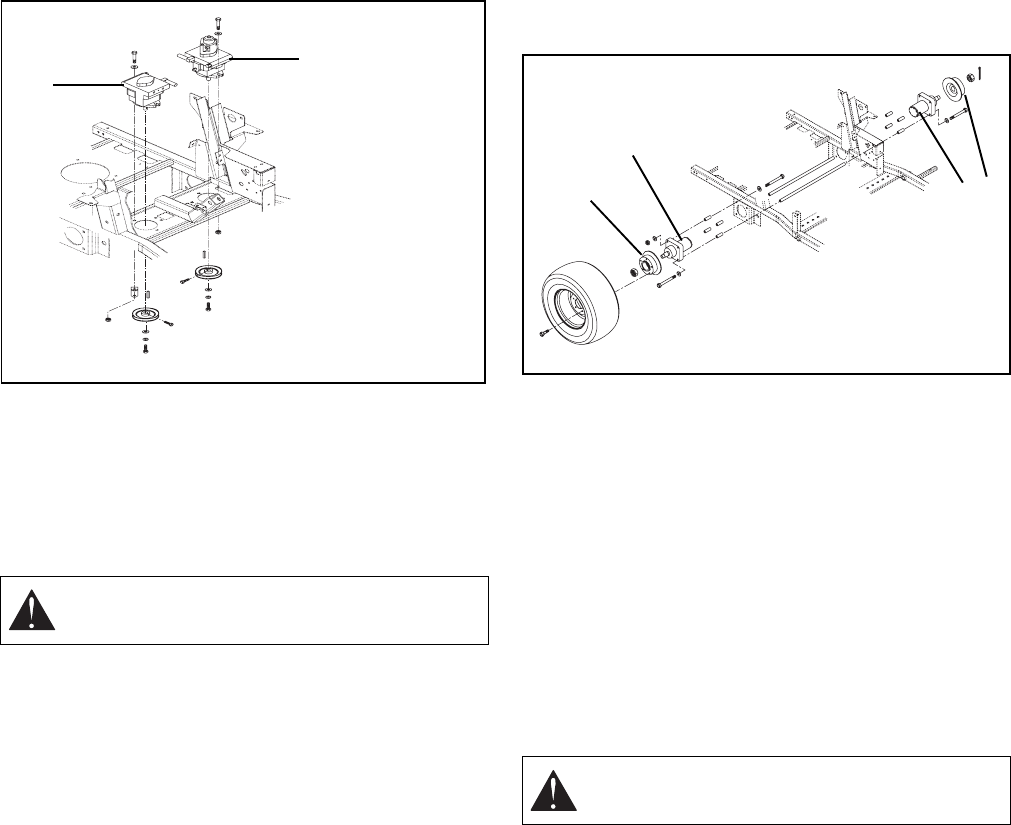

Figure 18

To Replace a Hydraulic Pump

1. Lift cover to full service position.

2. Remove the cross channel.

3. Clean hoses and fittings and mark for location.

4. Disconnect hoses from pump.

5. Remove belt from pulley.

6. Remove bolt and washers from end of shaft.

7. Loosen pulley lock bolt and slide pulley from shaft.

Remove and inspect square key. Replace key if

damaged.

8. Remove back bolt on pump and loosen front bolt.

9. Remove pump.

10.Insert the new pump into position with the front bolt

in the mounting flange slot.

11.Insert rear bolt and tighten both bolts.

12.Attach hydraulic hoses to correct ports and tighten.

13.Position square key in shaft keyway and slide

pulley into position.

14.Screw the bolt, washer and lock washer into the

end of the shaft. Tighten securely.

15.Tighten pulley lock bolt.

16.Place belt on pulley.

17.Replace cross channel.

18.Lower the cover and start the engine. Run the

engine for 1 - 2 minutes. After shutting off the

engine, check the hydraulic fluid level. The dipstick

should read between the high and low markings.

REPLACE WHEEL MOTOR

Each drive wheel is mounted to a hydraulic drive motor.

The drive motors are maintenance free. In the event of

a failure, the drive motors should be replaced.

Figure 19

To Replace a Drive Motor

1. Loosen the wheel lugs 1/4 turn. (Figure 19)

2. Jack the drive wheels off the ground and securely

support the unit.

3. Remove the wheel.

4. Remove the brake caliper assembly by removing

the two bolts.

5. Unscrew the axle bolt at the center of the hub and

remove the hub. The hub is a taper fit on the axle.

Use a wheel puller to assist in removal.

6. Mark the hydraulic lines and remove.

7. Unscrew the two bottom bolts and pull the

hydraulic motor out.

8. Remove the four bolt sleeves.

9. Insert the sleeves into the four bolt holes in the

new hydraulic motor.

10.Slide the motor into place and secure with two

bottom bolts. Apply Loctite to bolts.

11.Reattach hydraulic lines to proper ports and

tighten.

12.Clean the axle and the inside of the hub. Place hub

over axle and lightly tap into position. Screw the

axle nut onto the axle and tighten to 300-400 ft. lbs.

(406-542 Nm)

CAUTION: Some fluid will leak out. Clean up

any spills.

1

2

1. Hydrostat BDP

Pump

2. Variable-

Displace Pump

CAUTION: Some fluid will leak out. Clean up

any spills.

1

2

1

2

1. Hub 2. Hydraulic motor