SHUTDOWN. FLUSHING, AND STORAGE

WARNING

2.

If the pressure washerwill beexposedtofreezing

'

To reduce the risk of serious bodily injury.

Pressure Relief Procedure

including fluid injection and splashing

in

the

temperatures, drain all water out of the pump. If

'

you must store the pressure washer

in

freezing

temperatures, flush

it

with

a

50% antifreeze:

eyes, or on the skin, ALWAYS follow this

procedure whenever you shut

off

the pump,

the inlet hose into

a

bucket of 50% antifreeze

solution. This can be done by placing the end

of,

when checking or sewicing any part of the solution. Start the pressure washer. Trigger the

:

system, when installing or changing spray tips,

gun for

10

seconds, release the trigger for

10

:

and whenever you stop spraying for more than

seconds. Trigger and release about 10 times

or

10 minutes.

until the 50% antifreeresolution comes out ofthe

1.

Engage the gun trigger safety latch.

2. Turn the pressure washer

off.

CAUTION

4.

Shut

off

water supply.

3. Remove the power cord from the outlet.

5. Disengage the

triggersafetylatchandtrigger

thaw

it

in

a

warm room before trying to start

it.

the gun to relieve pressure, and engage latch

Do

not pour hot water on the pump;

it

maycrack

again.

~.

..

..

.

spray tip.

1: After using the chemical injector system,

it

should be flushed out with water or a 50%

washer with a clean, damp cloth.

antifreeze solution if unit will be exposed to

4.

Perform the appropriate maintenance. See the

freezing temperatures. This is best done by chart on page 7.

replacing the chemical container@) with a bucket

pressure

washer

as

described

in

start-up. Draw

of water or a 50% antifreeze

solution. Operate

water or antifreeze solution into both chemical

lines

until

it

passes through the injector. By

flushing the chemical injector system, you

will

help avoid unnecessary wear and prolongthe life

of components.

3. After each use, wipe all surfaces of the pressure

C

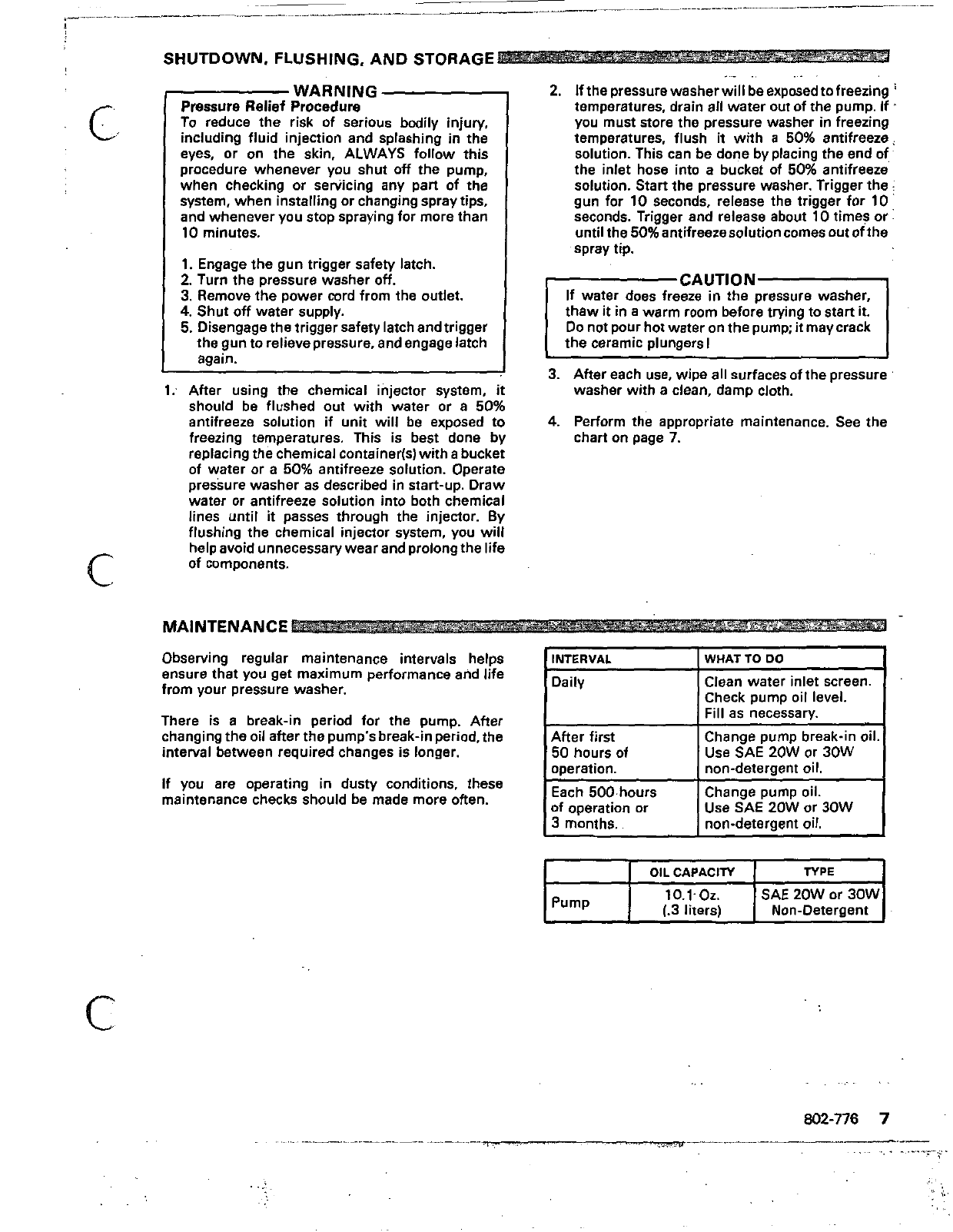

ObSeNing regular maintenance intervals helps

ensure that you get maximum performance and life

from your pressure washer.

There is

a

break-in period for the pump. After

changing the oil after the pump's break-in period, the

interval between required changes is longer.

If

you are operating

in

dusty conditions, these

maintenance checks should be made more often.

INTERVAL

WHAT

TO DO

Dailv

I

Clean water inlet screen.

I

Check pump oil level.

Fill as necessarv.

I

I

I

I

After first Change pump break-in oil.

50

hours of Use SAE 20W or 30W

of operation

or

Each 500.hours Change pump oil.

Use SAE 20W or 30W

I

OILCAPACITY

I

TYPE

Pump

(.3 liters)

10.1-Or.

SA€ 20W or 30W

Non-Detergent

C

802-776

7

.

. .~

..

~

PP

.

. . . .

.

.

.

.

,

~.

.