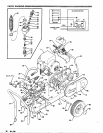

Reassembly

1.

Examine inlet valve surface and reverse if damaged.

(Both sides are lap surfaces.)

2.

Examine piston assembly for clean inlet surface.

If

damaged, replace and lubricate.

NOTE: CUP INSTALLATION

Wipe

cup inserter lightly

with

oil. Slip backup

ring onto piston. Force cup over inserter and

tion causes premature failure.

square

with

all surfaces. Faulty cup installa-

3.

Next replace piston spacer and retainer.

4.

Slip washer onto rod, screw on

nut

and torque to

60

in-lb.

ALWAYS USE NEW COTTER PIN.

5.

Examine cylinder wallsfor scoring oretching.These

conditions

will

cause premature wear of piston

assemblies. Replace if worn or damaged.

6.

Lubricate cylinder and replace O-rings and backup

rings (if defective).

7.

Position cylinders

in

their original order into manifold

chambers and carefully slip over rod ends onto the

pump.

8.

Replace flange nuts on studs and hand tighten both

sides. Then torque each side to

125

in-lb.

9.

Hand tighten locking nuts.

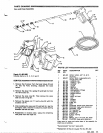

PUMPING SECTION CUTAWAY

SEALS AND

SLEEVES

Disassembly

1.

Remove discharge manifold and piston assemblies

as described.

2.

Remove both

(ME)

locking nuts from studs

3.

With soft mallet, tap inlet manifold loosefromcrank-

case.

4.

Place inlet manifold on pair of clearance blocks

with

crankcase side down, and drive out seals.

5.

Invert inlet manifold

with

CRANKCASE

SIDE

UP.

6.

Lubricate circumference of new Prrrrrm-A-Lube

seals, position

in

manifold with GARTER

SPRING

DOWN and drive into place.

7.

Examine sleeves for scoring or other damage before'

8.

If worn, grasp sleeve

with

pliers and pull off.

removing.

NOTE: This procedure will marthesleeveso use

only if sleeve is

to

be replaced.

9.

Remove O-ring and backup rings from piston rod.

Reassembly

1.

Place barrier slinger on rod

2.

Lubricate new o:rings and backup rings. Install first

O-ring

in

the O-ring groove on the piston rod. Position

backup ring against the shoulder

in

front of the first

O-ring, then the second O-ring. Be careful to avoid

damaging the O-rings when slipping them over the

piston rod threaded ends.

3.

Immerse sleeve

in

oil, carefully twist and push onto

rod. (Machined counter bore end first.)

4.

Replace seal retainers.

5.

Be careful when replacing inlet manifold,

so

the

in-

let seals are not damaged by the threaded rod ends.

6.

Replace locking nuts on studs.

7.

Reassemble piston assemblies and discharge mani-

fold as described.

case servicing.

Consult factory for your local distributor for crank-

DIAGNOSIS AND MAINTENANCE

PROBLEM

Low

pressure

PROBABLE CAUSE

Clean. Check more frequently.

Inlet suction strainer clogged.

Tighten or replace; use correct belt.

Belt slippage.

Replace nozzle, of proper size.

Worn nozzle.

SOLUTION

fluid or severe cavitation. Inadequate

Worn plunger cups. Abrasives

in

pumped

Install proper filter.

water supply.

..