DISCHARGE VALVES

&

VALVE SEATS

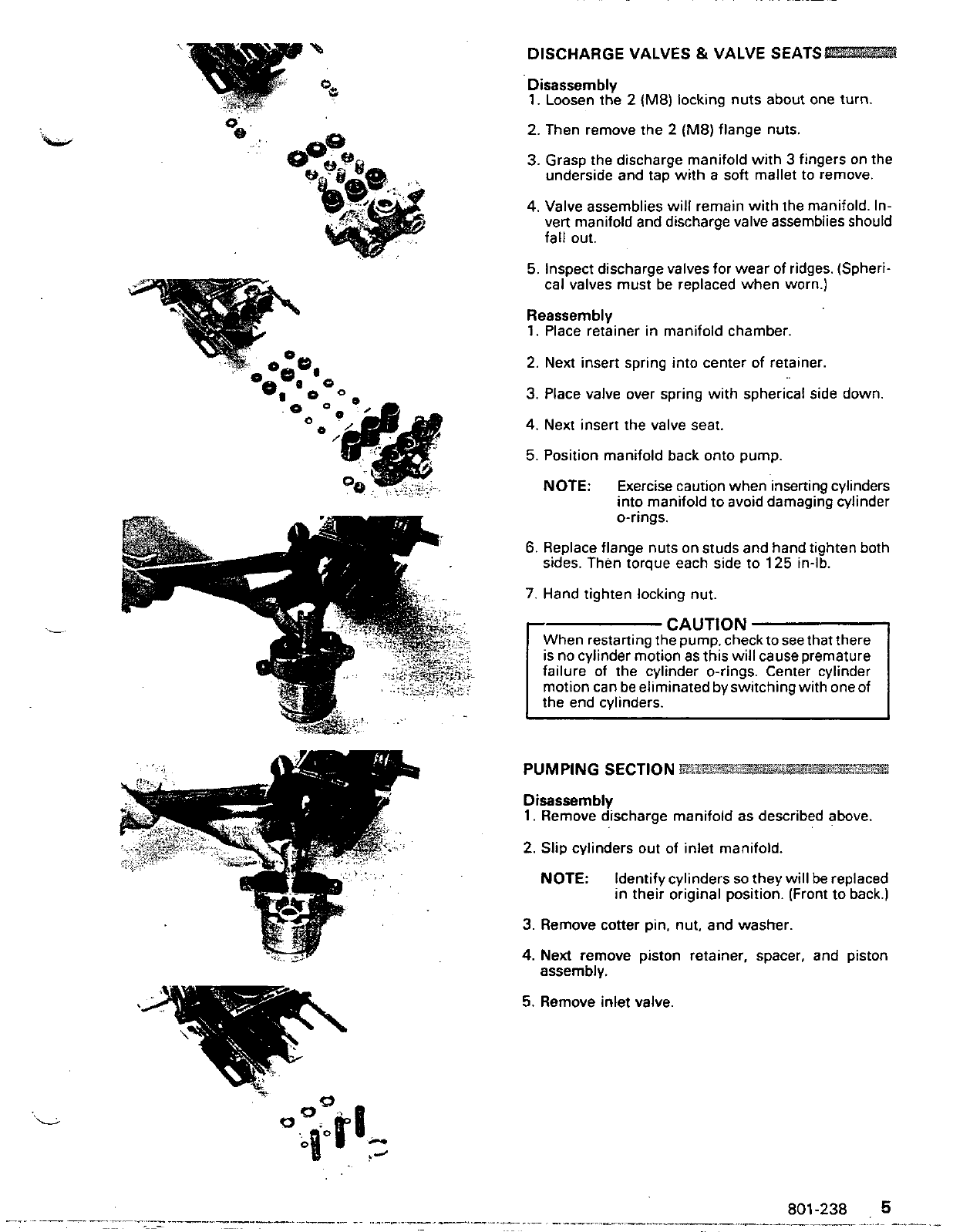

Disassembly

1.

Loosen the

2

(M8)

locking nuts about one turn.

2.

Then remove the

2

(M8)

flange nuts.

3.

Grasp the discharge manifold

with

3 fingers on the

underside and tap

with

a

soft

mallet to remove.

4.

Valve assemblies will remain with the manifold. In-

vert manifold and discharge valve assemblies should

fall out.

5.

Inspect discharge valves for wear of ridges. (Spheri-

cal valves must be replaced when worn.)

Reassembly

1.

Place retainer

in

manifold chamber.

2.

Next insert spring into center of retainer

3.

Place valve over spring

with

spherical side down.

4.

Next insert the valve seat

5.

Position manifold back onto pump.

NOTE: Exercise caution when inserting cylinders

O-rings.

into manifold to avoid damaging cylinder

6.

Replace flange nuts on studs and hand tighten both

sides. Then torque each side to

125

in-lb.

7.

Hand tighten locking nut.

-

When restarting the pump, checkto see that there

CAUTION

failure of the cylinder O-rings. Center cylinder

is no cylinder motion as this

will

cause premature

motion can beeliminated byswitchingwith oneof

the end cylinders.

1

PUMPING SECTION

BE2

Disassembly

1.

Remove discharge manifold as described above.

2.

Slip cylinders out of inlet manifold.

NOTE: Identify cylinders

so

they

will

be replaced

in

their original position. (Front to back.)

3.

Remove cotter pin, nut, and washer.

4.

Next

remove piston retainer, spacer, and piston

assembly.

5.

Remove inlet valve