CAUTION

B

the pump will result. Always be sure the water

Never run the cleaning

unit

dry. Costly damage to

supply is completely turned on before operating.

Inspect all connections for any leaks. Tighten if

necessary.

Cleaning

For cleaning

with

harsh chemicals,

see

the Chemical

In-

jector Kit manual

801-192.

need to hold the spray nozzle from the surface on a

For cleaning

with

clear water, test the distance

you

will

wood, hold the nozzle about

3

ft

(1

mm) from the sur-

scrap piece of similar material. For soft surfaces such as

face and gradually bring

it

closer, checking to

see

if the

high

pressure spray is damaging the surface. Always

off

the

dirt.

When you have finished cleaning, shut

off

hold the nozzle

at

an angle to the surface and "chisel"

the

unit

and trigger the spray gun to relieve pressure.

1

WARNING

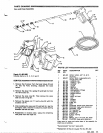

Follow these precautions when removing and

in-

stalling nozzles:

1.

Shut

off

the cleaning unit and trigger the

gun

to relieve pressure. Engage the trigger safety.

2.

Keep the nozzle and the tube pointed away

from you and everyone

else.

3.

Do

not put your hand over the tip to push the

nozzle into place. Grasp

it

from the side and

keep your fingers away from the

tip.

4.

Do

not let anyone

else

touch the spray valve

while you are changing nozzles.

5.

Be

sure the slip ring is pushed forward to lock

the nozzle in place before triggering the spray

gun.

Shutdown

and Care of

Unit

When the unit is not

in

use,

turn

off

the water supply.

When shuning down for the day or weekend, shut

off

the unit, shut

off

the water supply valve, and trigger the

gun

to relieve pressure. Wipe

off

the

unit

with a damp

rag.

Check the filter screen

in

the water inlet connection as

often as necessary, at least

daily.

Do

not operate the

unit with the inlet and filter screen removed.

DO

NOT

try

to adjust the unloader valve or change the

engine speed. Changing these settings may cause

ex-

wasted fuel and increased wear on parts and

will

void

cessive pressure, intermittent unloader operation,

the warranty.

THE

PUMP

MUST NOT BE RUN

DRY

and must be

temperatures.

Use

and store the unit where

it

will not be

drained of water before exposure to freezing

subjected to freezing temperatures. If water does freeze

freeze solution may be pumped prior to cold weather

in

the unit, thaw before trying to start.

A

50%

anti-

storage.

Use

only spray tips that are matched to the unit to avoid

excessive cycling and wear of the unloader valve.

See

ACCESSORIES.

pour hot water on a frozen pump.

A

sudden

I

temperature change may crack .the ceramic

plungers.

I

Do

not pump caustic materials.

Before extended storage, flush the pump with light oil.

Avoid dragging hose over an abrasive surface such as

cement. This causes~excessive wear and shorter hose

life.

Clean the intake line strainer daily.

Lubrication and Care

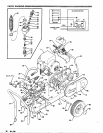

Fill the pump crankcase to the dot on the oil gauge win-

dow with

25

oz

(0.75

liters) of crankcase oil

(801-144)

or equivalent

SAE

40

weight hydraulic oil with antiwear

and

rust

inhibitor additives. Change the oil after the first

50

hours of operation'and then every

3

months or at

500

hour intervals.

NEVER

alter adjustment or modify the unloader

Altering or adjusting unloader

wi//

not

increase'

erformance of

unit.

"

4

801-238

""

""

--

-

---

-~-