6 Generac

®

Power Systems, Inc.

With LP gas, use only the vapor withdrawal system.

This type of system uses the vapors formed above the liq-

uid fuel in the storage tank.

The engine has been fitted with a fuel carburetion sys-

tem that meets the specifications of the 1997 California

Air Resources Board for tamper-proof dual fuel sys-

tems. The unit will run on natural gas or LP gas, but it

has been factory set to run on natural gas. Should the

primary fuel need to be changed to LP gas, the fuel sys-

tem needs to be reconfigured. See Section 1.6.4 (Page

6) for instructions on reconfiguration of the fuel system.

Recommended fuels should have a Btu content of at

least 1,000 Btus per cubic foot for natural gas; or at

least 2,520 Btus per cubic foot for LP gas. Ask your fuel

supplier for the Btu content of your fuel.

Fuel pressure for both natural gas and liquid propane

(LP) vapor set ups MUST be 11 inches to 14 inches of

water column (0.6 psi) at all load ranges.

1.6.2 FUEL CONSUMPTION

See the following chart for fuel supply requirements at

half and full load for both natural gas and LP vapor.

*Natural gas is in cubic feet per hour.

**LP is in gallons per hour/cubic feet per hour.

Gaseous fuels such as natural gas and liquid

propane (LP) gas are highly explosive. Even the

slightest spark can ignite such fuels and cause

an explosion. No leakage of fuel is permitted.

Natural gas, which is lighter than air, tends to

collect in high areas. LP gas is heavier than air

and tends to settle in low areas.

1.6.3 FUEL PIPE SIZING

See the following chart for proper sizing of fuel supply

piping. Insufficient fuel pipe size can cause hard start-

ing, poor engine performance and inability to carry

load.

NG and LP Vapor Pipe Sizing Chart:

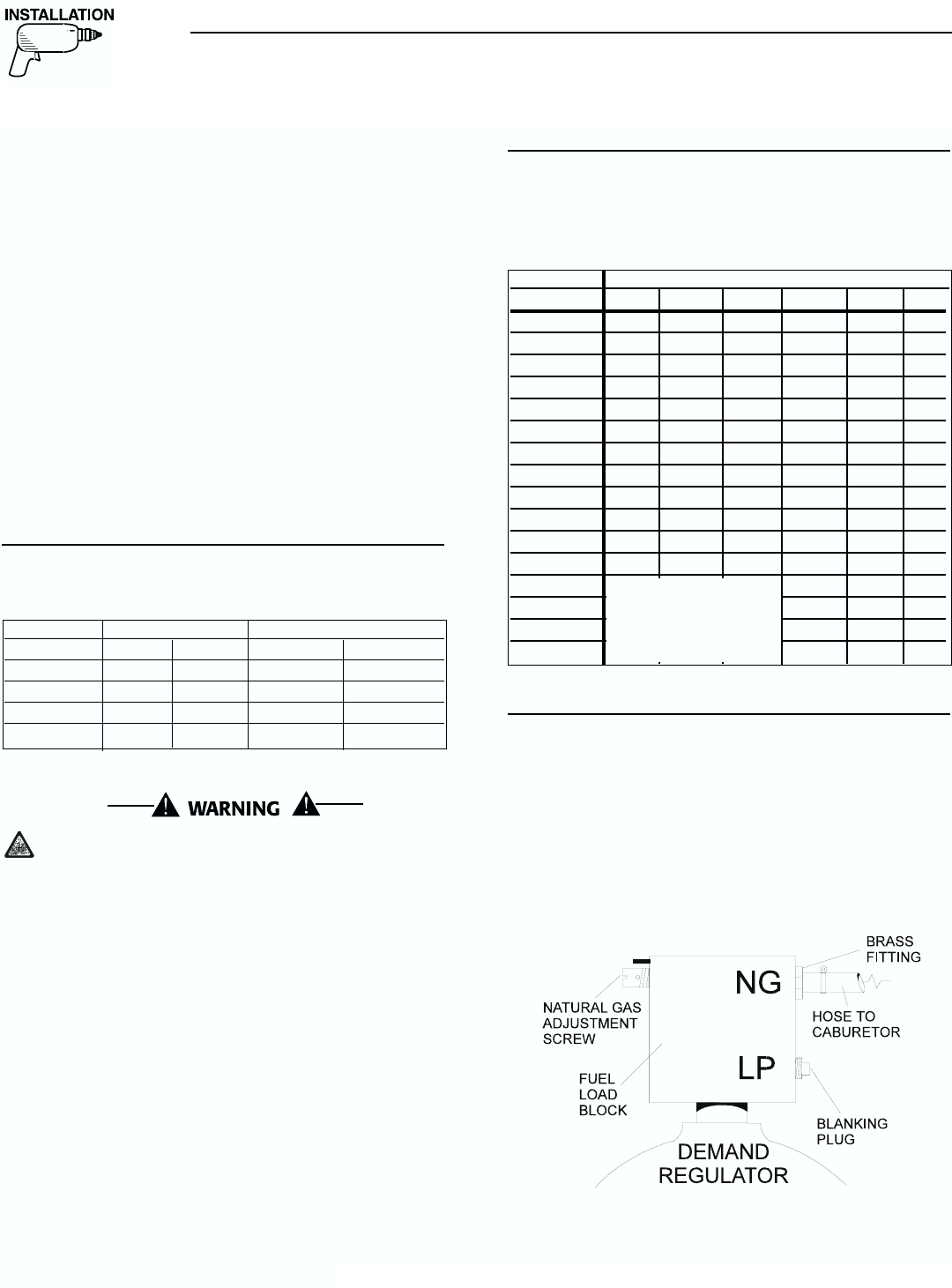

1.6.4 RECONFIGURING THE FUEL SYSTEM

To reconfigure the fuel system from NG to LP,

follow these steps:

1. Remove the carburetor fuel hose from the natural

gas port of the fuel load block and the brass fit-

ting (Figure 1.2).

2. Remove the blanking plug from the LP port of the

load block (Figure 1.2).

Figure 1.2 – Natural Gas Setup`

◆

◆

◆

Section 1 — Installation

Guardian Air-cooled Generators

Model # Nat. Gas (*) LP Vapor (**)

1/2 Load Full Load 1/2 Load Full Load

6 kW 74.1 105.3 0.86/31.30 1.08/39.30

8 kW 79.7 140.0 1.07/38.94 1.56/56.77

10 kW 100.8 177.9 1.16/42.21 2.15/78.24

Sound Attn. 84.6 126.6 1.06/38.57 1.7/61.86

Length of Pipe Iron Pipe Size (IPS Inches)

½" ¾" 1" 1 ¼" 1 ½" 2"

15' 76 172 345 750 1,220 2,480

30' 52 120 241 535 850 1,780

45' 43 99 199 435 700 1,475

60' 38 86 173 380 610 1,290

75' 77 155 345 545 1,120

90' 70 141 310 490 1,000

105 65 131 285 450 920

120 120 270 420 860

150 109 242 380 780

180 100 225 350 720

210 92 205 320 660

240 190 300 620

270 178 285 580

300 170 270 545

450 140 226 450

600 119 192 390

Consumption in

Cubic Feet Per Hour