26 Generac

®

Power Systems, Inc.

2.3 COOLING AND VENTILATING AIR

It is absolutely essential that an adequate flow of air

for cooling, ventilating and engine combustion be

supplied to the generator set. Without sufficient air-

flow, the engine/generator quickly overheats. Such

overheating can cause serious operating difficulties

and also may cause fire and personal injury. The

installer must make sure that sufficient air is avail-

able to the generator for cooling, ventilating and com-

bustion. The installer also must provide for a path

for exhausting the cooling air to the exterior of a com-

partment, if so equipped.

Never use discharged cooling air for heating or

permit such air to enter the vehicle interior.

This air contains deadly carbon monoxide gas

and other poisonous, flammable or explosive

gases.

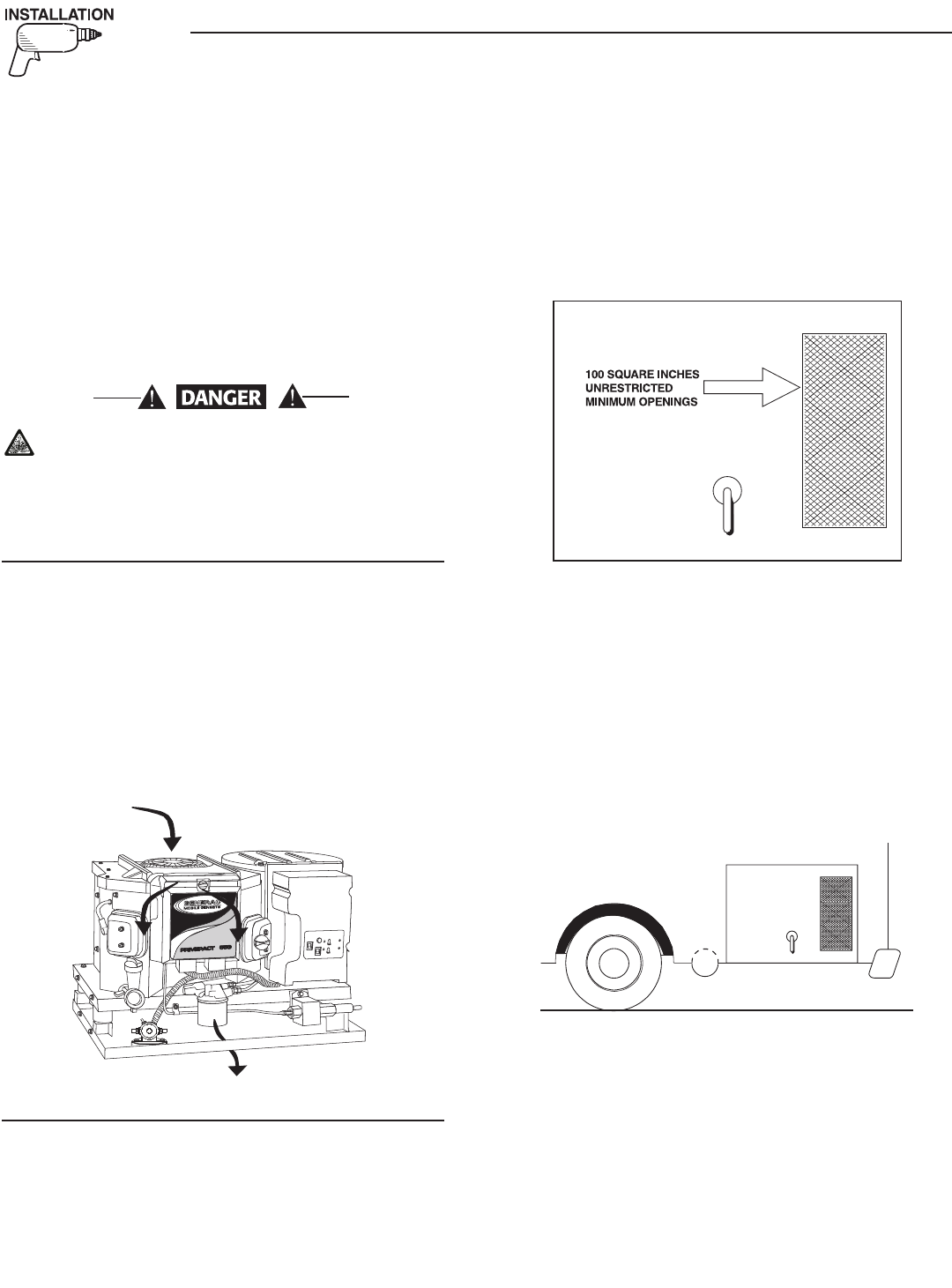

2.3.1 GENERATOR AIRFLOW

Engine operation drives cooling fans for the two-stage

cooling air system. A pressure fan draws cooling air

into the top of the generator (Figure 2.9). This airflow

cools the engine/generator and electronic compo-

nents. The second part of the cooling system, a suc-

tion fan, draws air that is heated from a hot engine

into a collector pan at the base of the unit. This heat-

ed air (although cooler than exhaust muffler) is then

deflected out the bottom toward the ground.

Figure 2.9 – Airflow Through Engine/Generator

2.3.2 COOLING AIR INLET OPENINGS

The minimum size of the air inlet opening, whether

the generator is housed in a conventional compart-

ment or not, is at least 100 square inches (see

Figure 2.10). This rule applies whether inlet air is

brought in through an opening in the compartment

door, an opening in the vehicle skirt, through duct-

work, or by any other means.

NOTE:

Screening, louvers or expanded metal that cover

air openings restrict airflow. You must compensate

for this by making the actual air opening propor-

tionately larger. See Section 2.3.3 (Page 27).

Figure 2.10 – Air Inlet in Compartment Door

NOTE:

Be sure to meet the minimum clearances illustrat-

ed in Figure 2.4 (Page 23).

When the unit is installed on a suspended mounting

system, one of several different methods of supplying

airflow may be used as follows:

• Provide a door in the vehicle skirt having an air

inlet opening (Figure 2.11).

Figure 2.11 – Suspended Mount: Inlet Door

• Using ductwork (Figure 2.12, Page 27). The

installer must be sure air is available to the top of

the generator since air inlets are located at the top.

• By providing an opening in the vehicle skirt and

space behind the generator for cooling airflow

(Figure 2.13 Page 27). Recommended clearance

behind the back of the generator is at least 1/2 inch

(13 mm).

◆

◆

Section 2 – Installation

PRIMEPACT 50 and 70 (50Hz) Recreational Vehicle Generators