Maintenance

a steady ow of oil to ow out from under the

housing. Retighten the capscrews. Do this for

both pumps.

Note: Hydraulic reservoir can be pressurized up

to 5 psi to speed this process.

6. If either drive wheel still does not rotate, stop

and repeat steps 4 and 5 above for the respective

pump. If wheels rotate slowly, the system may

prime after additional running. Check oil level

as stated in Check the Hydraulic Oil Level

section.

7. Allow unit to run several minutes after the charge

pumps are “primed” with drive system in the full

speed position. Check oil level as stated in Check

the Hydraulic Oil Level section.

8. Check hydro drive linkage adjustment as stated in

Hydro Drive Linkage Adjustment section in

Adjustments.

Wheel Hub-Slotted Nut

Torque Specication

Service Interval: After the rst 100 hours

Every 500 hours thereafter

When tightening the slotted nut on the wheel motor

tapered shaft:

1. Torque the slotted nut to 100 ft-lb (136 N-m).

2. Further tighten the nut until the next set of slots

line up with the cross hole in the shaft.

3. Replace cotter pin.

Note: Do not use anti-seize compound on the wheel

hub.

Inspect PTO Clutching Belt

Tension

Service Interval: After the rst 2 hours

Check every 2 hours

for the rst 8 hours of

operation.

Every 40 hours thereafter.

1. Stop engine and wait for all moving parts to stop.

2. Engage PTO lever.

3. Look through the round hole in the left rear

corner of the engine deck to inspect blade

clutching belt tension. Bolt on blade engagement

linkage bellcrank and indicator arm should align

within 1/16 inch (1.6 mm) (see Figure 14). Refer

to PTO Engagement Linkage for adjustment.

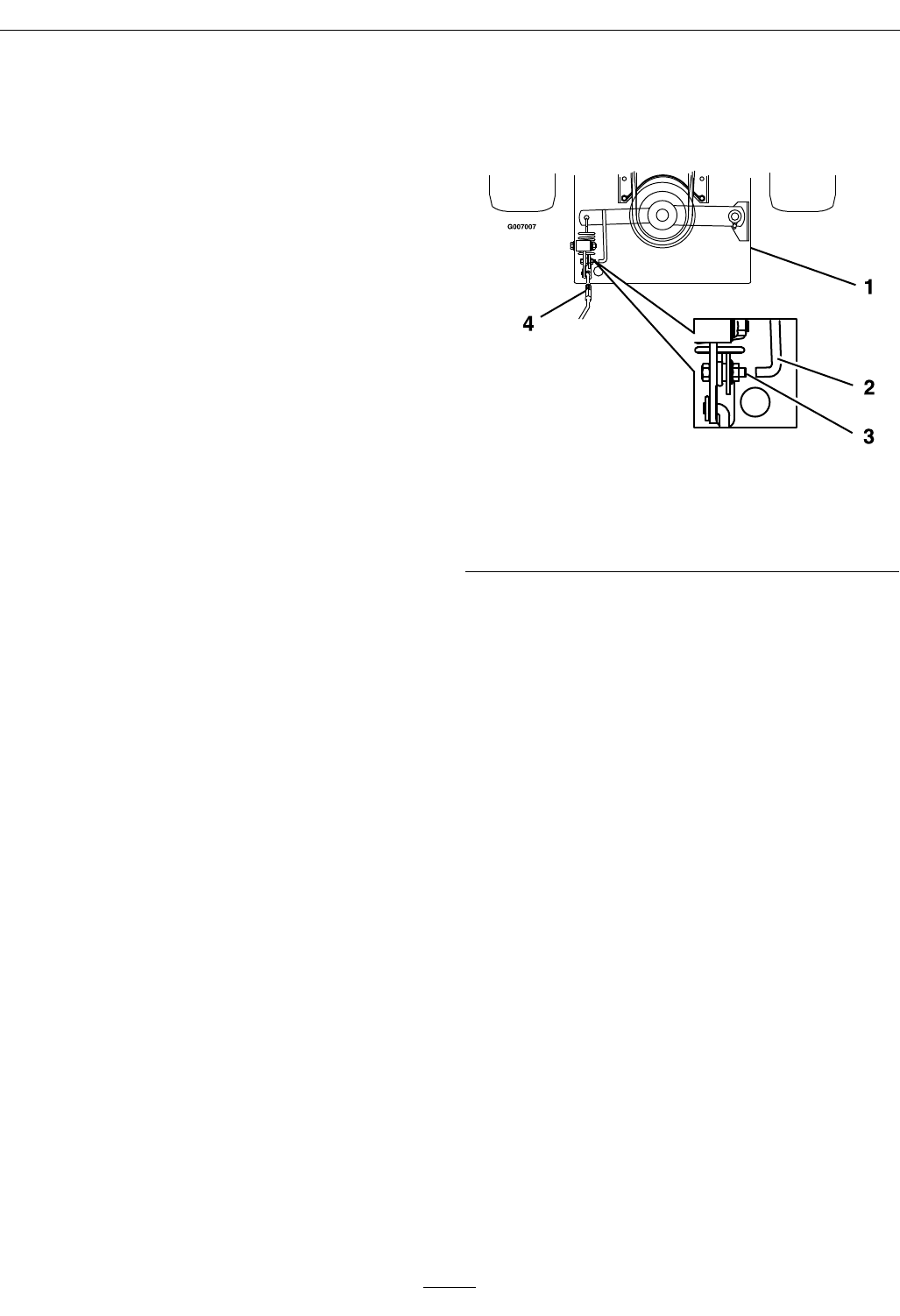

Figure 14

1. Engine deck 3. Align bolt to indicator

within 1/16 inch (1.6

mm)

2. Indicator 4. Turnbuckle

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242”

or “Fel-Pro, Pro-Lock Nut Type” are used on the

following fasteners:

• Pump sheave setscrews.

• Square head setscrews on hydro pump control

arms.

• OPC lever setscrews.

• Lower sheave retaining bolt on clutch arm.

• Shoulder bolts in ends of speed control crank.

• Sheave retaining bolt in end of engine crankshaft.

• Fuel tank bulkhead tting threads

Adhesives such as “Loctite RC/609 or RC/680” or

“Fel-Pro Pro-Lock Retaining I or Retaining II” are

used on the following:

• OPC lever hubs and cross-shaft.

Note: Care must be used not to bond the

bearing, next to each OPC hub, to the cross-shaft

which could cause binding of the OPC levers and

erratic operation.

• Fuel tank studs, where studs are inserted into tank.

31