Maintenance

2. To tighten transmission belt, loosen the 3/8 inch

nyloc nut on transmission belt idler pulley. Slide

bolt inward in slot and retighten nyloc nut.

3. When properly adjusted, the belt should have 1/2

inch (1.3 cm) of deection with three pounds

of pressure on the belt midway between the

transmission and engine pulley.

Wheel Drive Belt Pulley

Scrapers

1. Stop engine and wait for all moving parts to stop.

Engage parking brake. Remove key or spark plug

wire(s).

2. Be sure mud and grass scraper, on each side,

is adjusted properly and centered in the pulley

grooves. The pointed part of the scraper should

be centered and as deep in the pulley groove as

possible without rubbing at any point.

Engine to Mower Deck Belt

1. Stop engine and wait for all moving parts to stop.

Engage parking brake. Remove key or spark plug

wire(s).

2. Check the adjustment of the lower blade drive

linkage located between the bellcrank on the

engine deck and assist arm on the mower deck.

Lengthen or shorten the linkage. When properly

adjusted, there should be 1/16 inch to 1/8 inch

(2–3 mm) of clearance between bell-crank and

transmission output shaft when belt is engaged.

Make sure the assist arm is against the rear assist

arm stop on the deck (see Figure 13). Push the

lever down to the disengaged position. The assist

arm should contact the front assist arm stop on

the deck. If it does not contact, readjust so that

the bellcrank is closer to the transmission output

shaft.

3. Belt must be tight enough to not slip during heavy

loads while cutting grass. Over-tensioning will

reduce belt and spindle bearing life. To adjust

belt tension, loosen the 5/16 inch whizlock nut

on turnbuckle and rotate the turnbuckle; rotate

turnbuckle toward rear of mower to tighten, and

toward front of mower to loosen belt tension (see

Figure 13). Leave a minimum of 5/16 inch (.79

cm) of the eyebolt threads engaged on both ends

of the turnbuckle.

For 48” Decks: If there is no adjustment left in

the turnbuckle and the belt is still loose, the rear

idler pulley can be repositioned in the front hole

(See Figure 12). The belt guide located next to

the pulley must also be repositioned in the front

hole when the pulley is moved. The turnbuckle

will need to be readjusted.

Check belt tension after the rst hour of operation

and at least twice during the rst 24 hours of

operation. Adjust as necessary.

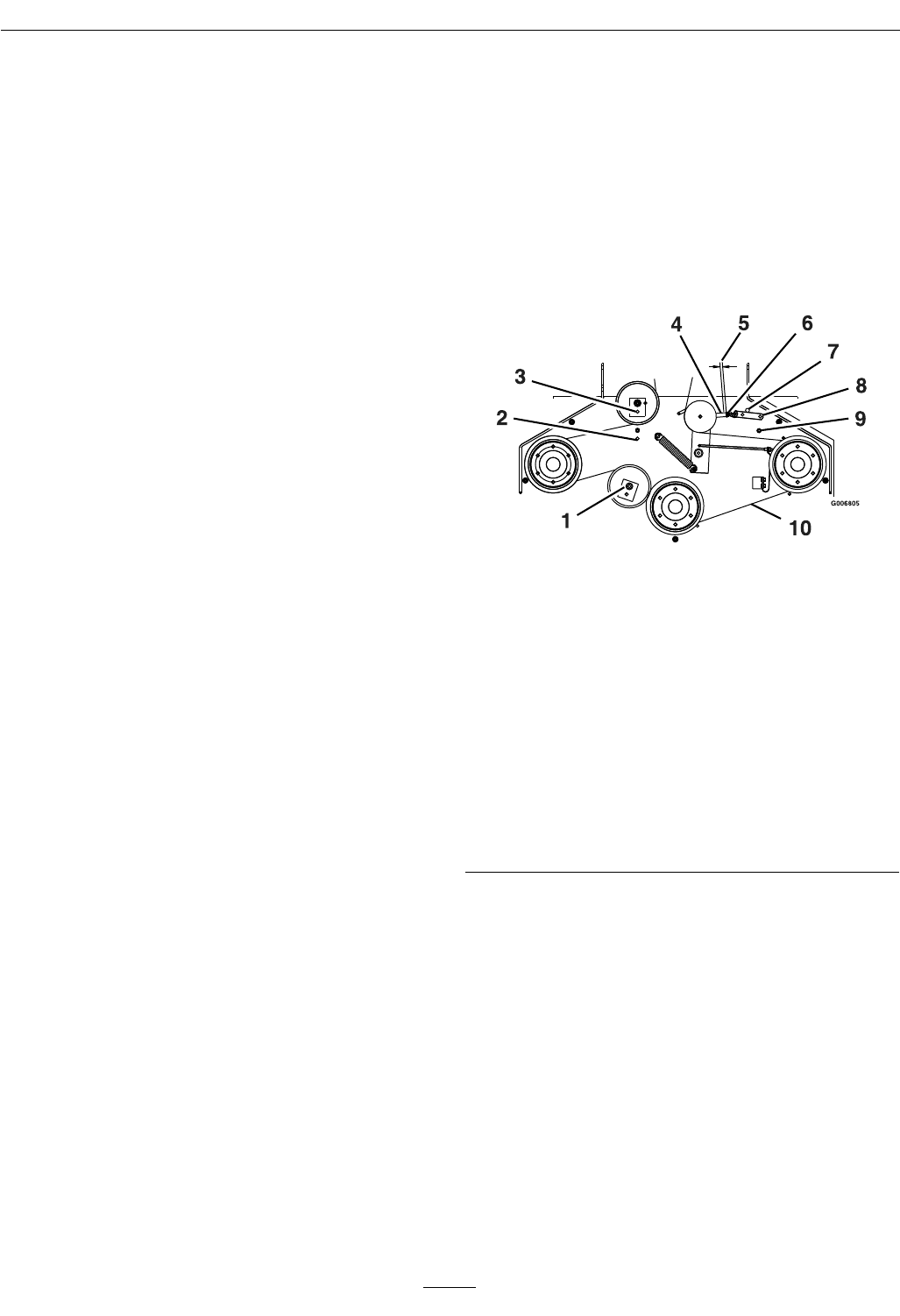

Figure 13

48 inch Deck Shown for Reference Only

1. Pulley location for Metro

2. Pulley can be moved to the front position to tighten the

belt when there is no adjustment left in the turnbuckle

(48 inch deck only)

3. Belt guide must be moved to the front position if the

pulley is moved. (48 inch deck only)

4. Turnbuckle

5. 5/16 inch (.79 cm) minimum engagement

6. 5/16 inch whizlock nut

7. Rear Assist Arm Stop

8. Assist Arm

9. Front Assist Arm Stop

10. Point “A”

4. Proper belt tension will require about 10 lb (4.5

kg) side pull on belt, halfway between pulleys (see

Figure 13, item 10–Point A) to deect belt 1/2

inch (12 mm).

5. Check belt guide under the engine deck to see that

it is properly set (see Belt Guide Adjustment

section). Also check the blade brake adjustment

(see Blade Brake Adjustment section).

28