Page 38

CARE AND MAINTENANCE

PROCEDURE FOR ELECTRIC CLUTCH ADJUSTMENT

Electric clutches require periodic Air Gap adjustments for extended life. Listed below is

both an Air Gap adjustment procedure and an Ohms test to check for a faulty coil within the

clutch. No replacement parts are available to repair a faulty assembly. The entire clutch

must be replaced.

A. AIR GAP ADJUSTMENT

1.

It is not necessary to remove the clutch from the motor.

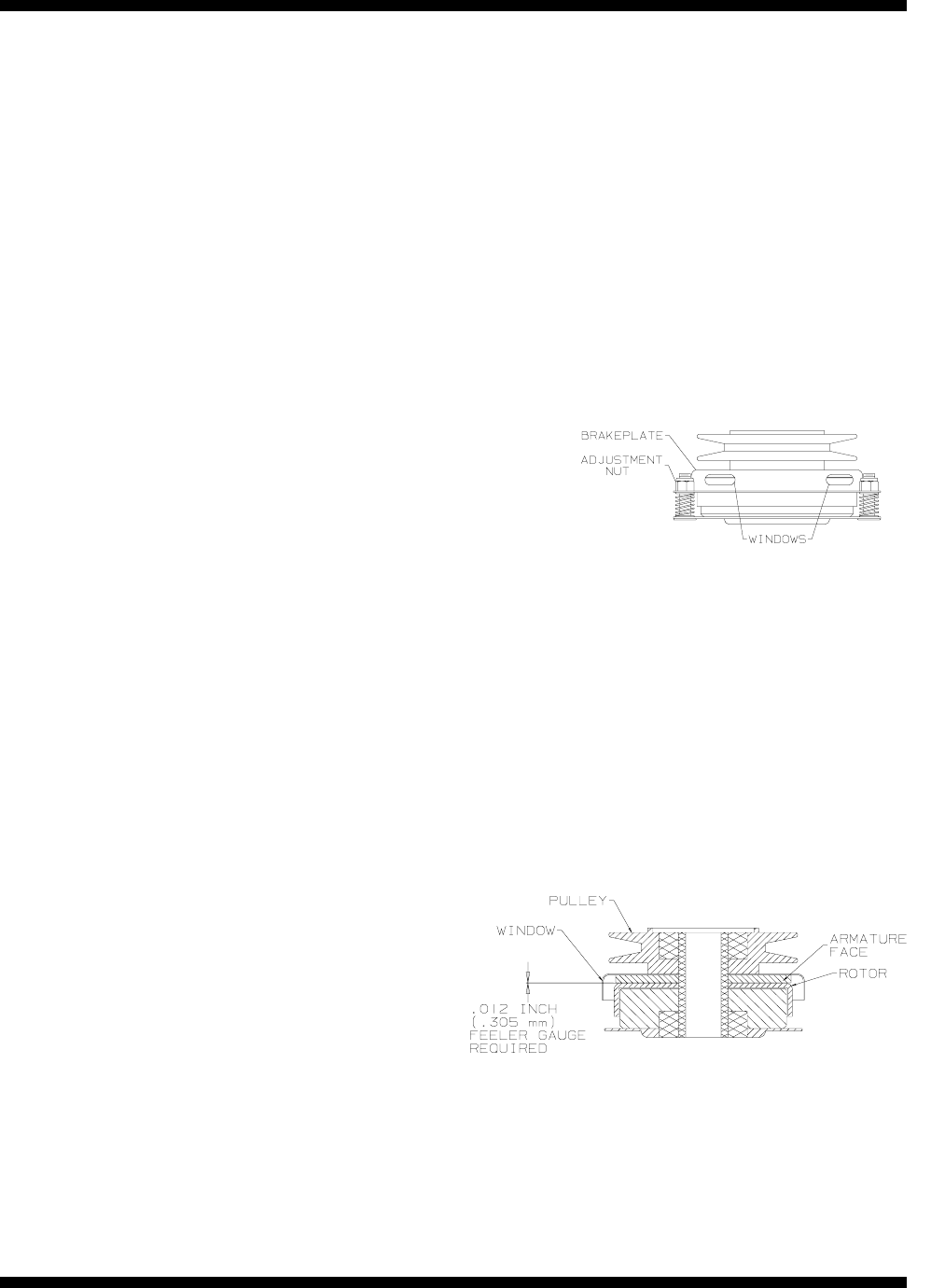

2. Locate the three holes in the brake plate, one

near each adjustment nut. (Figure 1)

3. Insert a .012 inch feeler gauge into one of the

three windows. Be careful to position the

feeler gauge between the rotor and armature

faces. (Figure 2)

4. Tighten the adjusting nut adjacent to the

window with the feeler gauge inserted until the

gauge fits snugly between the rotor and armature.

The gap should not be so tight that the feeler gauge

cannot be reinserted after removal.

5. Repeat Steps 5 and 6 at the other two windows.

6. Recheck the air gap at each window and make minor adjustments

as necessary to achieve a consistent .012 inch air gap.

B. OHMS TEST

1. Disconnect clutch from mower wiring

harness.

2. Attach the two leads on multi-meter to

the two wires coming from the electric

clutch.

3.

The reading you receive should be

between2.4 to 2.9 OHMS.

4.

If the resistance is outside this range

the clutch coil is faulty.

5. If the clutch coil is faulty, the clutch must be

replaced.

Figure 1

Figure 2