9

E

N

G

L

I

S

H

Models 2ZRP8, 2ZRP9

Dayton Operating Instructions and Parts Manual

governed to operate at speeds close

to 3600 RPM (60Hz) throughout the

operating load range. The no load

speed (before a load is applied) will be

just a bit higher than the load speed

and is normally set to 3750 RPM.

DO NOT TAMPER

WITH THE

GOVERNOR MECHANISM, CHANGE THE

SETTING EXPERIMENTALLY, OR PUSH

THE THROTTLE OPEN IN AN ATTEMPT TO

GENERATE MORE ELECTRICAL CURRENT;

EQUIPMENT DAMAGE OR PERSONAL

INJURY MAY RESULT.

GOVERNOR SPEED ADJUSTMENT SHOULD

BE MADE ONLY BY A Dayton Customer

Service Representative.

CHECKING ENGINE OIL:

Check oil level before each operation

and ensure that it is maintained per

Preparing the Generator; Engine Oil

Capacity section.

CHANGING ENGINE OIL:

Change oil after the first 20 hours of

operation. Thereafter it should be

changed every 100 hours.

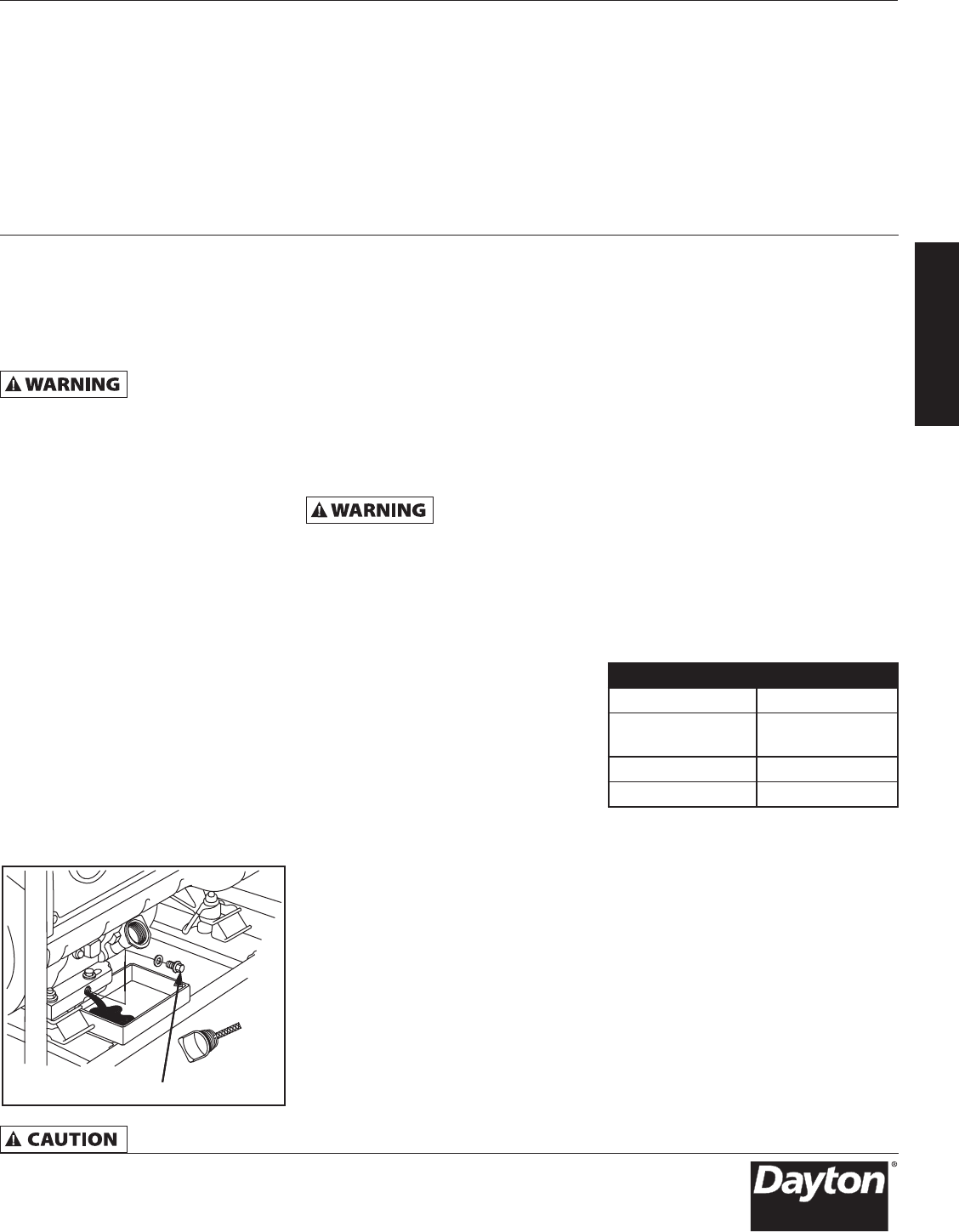

1. Make sure the unit is on level ground.

Run the engine to warm the oil.

2. Stop the engine.

3. Remove the oil drain plug.

Oil being drained

may be hot. To

reduce the risk of burn injury, handle

with care. Dispose of used oil properly.

4. Drain oil while engine is warm, into a

suitable container.

5. Reinstall the oil drain plug.

6. Remove oil gauge and refill with new oil.

7. Check the oil level as instructed in

Preparing the Generator; Engine Oil

Capacity section.

8. Wipe up any spilled oil.

AIR CLEANER:

RISK OF FIRE OR

EXPLOSION. DO NOT

USE GASOLINE OR LOW FLASH-POINT

SOLVENTS TO CLEAN THE ELEMENT.

CLEAN THE ELEMENT IN A WELL

VENTILATED AREA. ENSURE THAT NO

SPARKS OR FLAMES ARE NEAR THE

WORKING AREA, THIS INCLUDES ANY

APPLIANCE WITH A PILOT LIGHT.

CAUTION: NEVER RUN THE ENGINE

WITHOUT THE AIR FILTER, SERIOUS

DANGER CAN RESULT.

Check the air cleaner daily or before

starting the engine. Check for and

correct heavy buildup of dirt and

debris along with loose or damaged

components.

1. Unsnap the air cleaner cover and

remove the elements.

2. Clean the elements:

FOAM PRE-CLEANER ELEMENT: Wash

the foam pre-cleaner element in warm

water with detergent. Rinse the foam

pre-cleaner element thoroughly until

all traces of detergent are eliminated.

Squeeze out excess water, but do not

wring. Allow the foam pre-cleaner

element to air dry.

Saturate the foam pre-cleaner element

with new engine oil. Squeeze out all

excess oil. DO NOT put engine oil on

the foam damper.

NOTE: Clean the foam pre-cleaner

element every 25 hours of operation

(more often under extremely dusty or

dirty condition)

PAPER AIR CLEANER ELEMENT: Do

not wash the paper element or use

pressurized air, as this will damage the

element. Clean by gently tapping the

element to remove dust. Replace the

element if damaged, bent or extremely

dirty. Handle new element carefully; do

not use if the sealing surfaces are bent

or damaged.

NOTE: Replace the paper element every

100 hours (more often under extremely

dusty conditions.)

Reinstall the foam pre-cleaner element

and the paper air cleaner element.

Close air cleaner cover and clasp shut.

CLEANING AND GAPPING SPARK PLUG:

Recommended Spark Plug:

If the plug is contaminated with

carbon,remove it using a plug cleaner

or wire brush. Check the spark plug gap

and reset it if necessary. The spark plug

gaps are listed below. To change the

gap, bendthe side-electrode only, using

a spark plug tool. Install and tighten the

spark plug. Connect the spark plug lead.

SPARK ARRESTOR:

If the generator has been running, the

muffler will be very hot. Allow it to cool

before proceeding.

NOTE: Remove and clean spark arrester

every 100 hours or as necessary.

NOTE: Product users on United States

forest service land, and in some states,

Engine Honda

Spark Plug NGK BPR6ES

Spark Plug Gap 0.7 - 0.8 mm

(0.03 in.)

Torque - New 8.7-10.9 ft-lb

Torque - Retighten 16.6-19.5 ft-lb

OIL DRAIN PLUG