Drive Control

Refer to “Auger and Drive Control Cables” of the Assembly & Set-Up - 3

for instructions to adjust the drive control. To further check the

adjustment, proceed as follows:

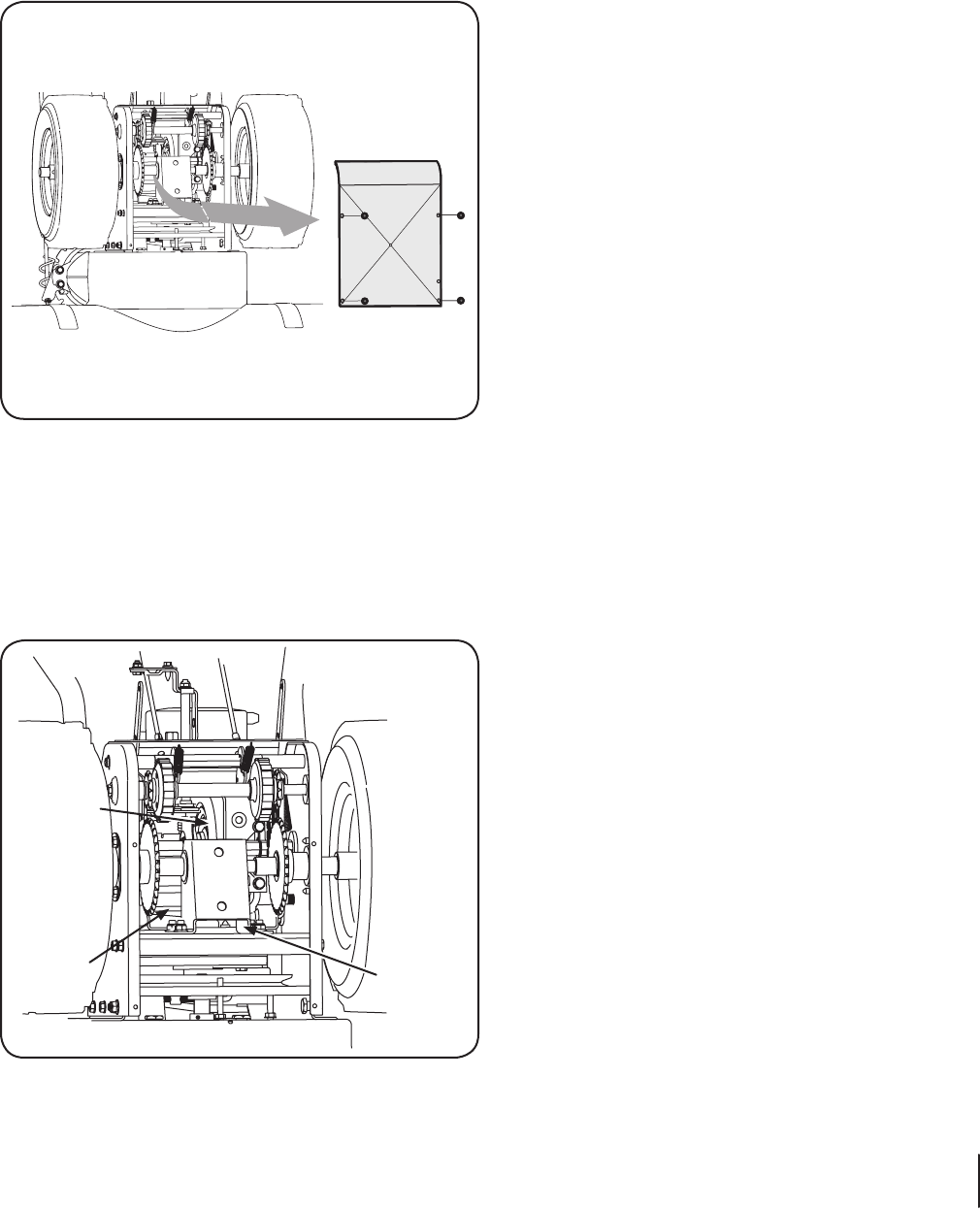

1. With the snow thrower tipped forward (before tipping the

machine on to the front housing, run the fuel tank empty),

remove the frame cover underneath the snow thrower by

removing the self-tapping screws. See Figure 6-6.

2. Locate the opening between the axle support bracket and

the front frame support (See Figure 6-7). Looking through

this opening, with the drive control released, there must be

clearance between the friction wheel and the drive plate in

all positions of the shift lever.

3. With the drive control engaged, the friction wheel must

contact the drive plate. Refer to Figure 6-7.

4. If there is no friction wheel clearance when the drive

control is disengaged, or the friction wheel does not solidly

contact the drive friction plate when the drive control is

engaged, re-adjust the lock nut on the lower end of the

drive cable following the instructions in the Assembly &

Set-Up .

5. Reassemble the frame cover.

Chute Directional Control

The distance snow is thrown can be adjusted by adjusting the

angle of the chute assembly. Move the remote chute lever on the

control panel forward to pivot the upper chute down; move the

lever rearward to pivot the upper chute upward.

The chute directional control is located on the left side of the

snow thrower. To change the direction in which snow is thrown,

crank clockwise to discharge to the left and counterclockwise to

discharge to the right.

Auger Control

Refer to the Assembly & Set-up for instructions on adjusting the

auger control cable.

Skid Shoes

Refer to the Assembly & Set-up for instructions on adjusting the

skid shoes.

Tire Pressure

Refer to the Assembly & Set-up for instructions on adjusting the

tire pressure.

Off-Season Storage

If the snow thrower will not be used for 30 days or longer, follow

the storage instructions below.

1. Lubricate the machine as instructed earlier in this .

2. Store in a clean, dry area.

3. If storing the snow thrower in an unventilated area,

rustproof the machine using a light oil or silicone to coat

the snow thrower.

4. Clean the exterior of the engine and the snow thrower.

NOTE: Refer to the engine operator’s manual Maintenance for

information on storing your engine.

Figure 6-7

Figure 6-6

Axle

Support

Bracket

Opening

Drive

Plate

Friction

Wheel

17Section 6 — Maintenance & adjuStMentS