22

Figure 24

ON DEMAND FOUR WHEEL DRIVE

The On Demand Four Wheel Drive system

automatically delivers power to the front axle

whenever the need for additional traction is sensed

by the transmission. No action from the operator is

required for engagement.

TRACTOR WEIGHTING

When implements are installed on either the front or

rear of the tractor, the normal balance of the tractor

is altered.

• As a rear mounted implement is raised to the

transport position, the balance point of the

tractor shifts rearward, which may result in a

loss of steering control and tractor stability.

• When a front mounted implement is raised, the

balance point shifts forward and may result in a

loss of traction and stability.

To counterbalance these weight shifts, weight

should be added to the tractor in the form of either

cast iron weights or liquid ballast. However, only

enough weight should be added to obtain good

traction, control, and stability. Excessive weight will

unnecessarily load down the tractor’s engine and

transmission.

NOTE: When adding weight to the tractor, it may be

necessary to increase the inflation pressure in the

tires.

Front Weights

To counterbalance three point hitch mounted

equipment, a weight bracket/bumper kit and cast

iron weights are available from your Cub Cadet

dealer.

When mounting optional Cub Cadet equipment on

the rear of the tractor, such as a rotary tiller, rotary

cutting deck, or a rear finish mower, the weight

bracket and a minimum of four suitcase weights

should be used.

For all other rear mounted equipment, follow the

guidelines provided in the implement’s Operator’s

Manual to determine how much weight is needed to

counterbalance the equipment.

If guidelines are not available, ballast the tractor so

that a minimum of approximately 40% of the

machine weight is on the front wheels.

Weighting the Rear of the Tractor

Adding weight to the rear of the tractor is not

required for most Cub Cadet front mounted

equipment currently available for this tractor.

However, if installing only the optional front end

loader (without the back hoe), weight must be

added to the rear of the tractor. The most common

methods of adding weight are filling the rear wheels

with liquid ballast (usually a calcium chloride and

water solution) or mounting a rear weight box.

Liquid Ballast

Properly filling the rear tires with liquid ballast

increases the weight of each rear wheel to

approximately 200 pounds, which should provide

adequate counterbalance.

Because special equipment and a familiarity with

the practice is required, only a qualified tire

technician should perform this procedure. Consult

with your Cub Cadet dealer about having liquid

ballast added to your tires, and for any special

maintenance instructions after the procedure is

performed.

Rear Weight Box

A weight box will provide adequate counterbalance

if the following criteria is met:

• The weight box and contents must total a

minimum of 200 pounds.

• The weight box must be positioned a minimum

of approximately 20 inches rearward of the rear

axle, and be carried no more than 12 inches

from the ground.

If the weight box is positioned closer to the rear

axle or carried higher, additional weight must be

added to effectively counterbalance the front

loader.

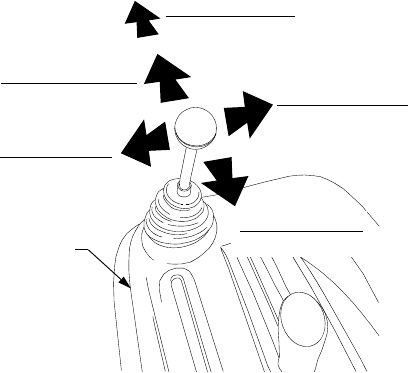

ANGLE RIGHT

ANGLE LEFT

RH FENDER

COVER

DUMP BUCKET

ROLLBACK

LOWER HITCH

FLOAT HITCH

RAISE HITCH

RAISE BOOM

BUCKET

LOWER BOOM

FLOAT BOOM