12

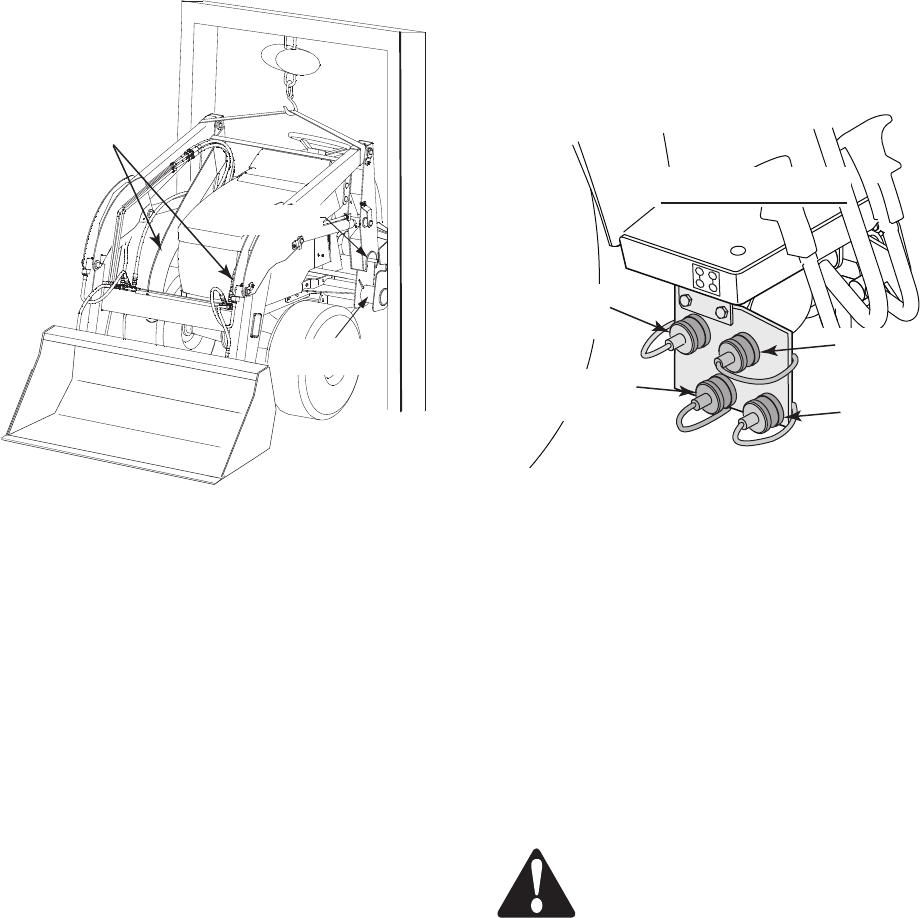

Figure 7

• Stop the tractor engine and set the tractor’s parking brake

before leaving the operator’s seat. Proceed to “Installing the

Front Loader” in this section.

Pre-Charging Cylinders for Initial Installation

If an overhead lift is not available, the front loader cylinders can be

used to position the loader for installation. To position the loader,

proceed as follows:

• Start the tractor and carefully drive the tractor to position it

along the right side of the front loader, facing in the opposite

direction of the loader.

IMPORTANT: Stop the tractor engine. Set the tractor’s parking

brake before leaving the operator’s seat.

• Remove the four protective caps from the male couplers at

the free ends of the hydraulic hoses.

• Locate the color coded protective plugs in the female

hydraulic couplers on the lower right side of the tractor, just in

front of the right/rear tire. Refer to Figure 8.

• Using the color coded plugs and matching color coded

washers on the loader hoses to guide you, remove the plugs

and connect each loader hose to the appropriate hydraulic

coupler. Refer to Figure 8.

NOTE: If for any reason the color coded plugs of the outlets

and/or caps and washers of the hoses are unavailable or incor-

rect, follow the routing of each hydraulic hose/tube to the loader

cylinders to determine the loader connection of each hydraulic

line. Use the following information to determine the appropriate

hose to hydraulic outlet connection. Working from the right side of

the tractor, facing the hydraulic outlets, proceed as follows:

Outlet #1 (lower left) - connect the hydraulic line from the piston

ends of the bucket cylinders (roll back bucket).

Outlet #2 (upper left) - connect the hydraulic line from the cylinder

body ends of the bucket cylinders (dump bucket).

Outlet #3 (upper right) - connect the hydraulic line from the piston

ends of the boom cylinders (lower boom).

Outlet #4 (lower right) - connect the hydraulic line from the

cylinder body ends of the boom cylinders (raise boom).

Figure 8

• Check for ties that may be installed end to end around both of

the boom cylinders. Cut and remove the ties if present.

IMPORTANT: Re-start the tractor and perform the hydraulic test

described below in “Checking Implement Control Lever Opera-

tion” to assure that all implement control lever movements result

in the loader movements described. If loader movements do not

respond correctly, turn the tractor’s engine off, set the parking

brake and recheck all hydraulic connections as described above.

Loader control movements must be correct before proceeding.

IMPORTANT: If you were unable to connect the pistons of the

two bucket cylinders to the bucket rear mounting brackets as

instructed earlier, use the tractor’s implement control lever to

extend the pistons as needed and connect the cylinders now.

WARNING: Use extreme caution when perform-

ing the loader boom cylinder charging procedure.

NOTE: For packaging purposes the two boom cylinders are

fully collapsed. This results in the loader masts being positioned

beyond their normal vertical position, which causes the loader’s

center of gravity to be shifted rearward of normal. Consequently

the loader hitch arms may not pivot downward when initially

extending the boom cylinders pistons. When performing the

initial priming of the boom cylinders, it will be necessary to apply

downward force on the front of the bucket (e.g.; placing weight on

bucket shave plate; an assistant applying downward pressure on

the bucket) to pivot the hitch arms downward and raise the loader

masts.

• While observing the hoses to ensure they do not become

pinched or stretched, slowly and carefully move the imple-

ment control lever rearward to extent the boom cylinders. The

loader hitch arms should pivot downward toward the ground

and raise the bottoms of the masts.

Base of Mast

LH Mount

Tubular Bar

Loader

Hitch Arms

2

1

3

4

Lower Boom

(#3-Blue)

Raise Boom

(#4-Green)

Dump Bucket

(#2-Yellow)

Curl Bucket

(#1-Red)

Hydraulic Outlets