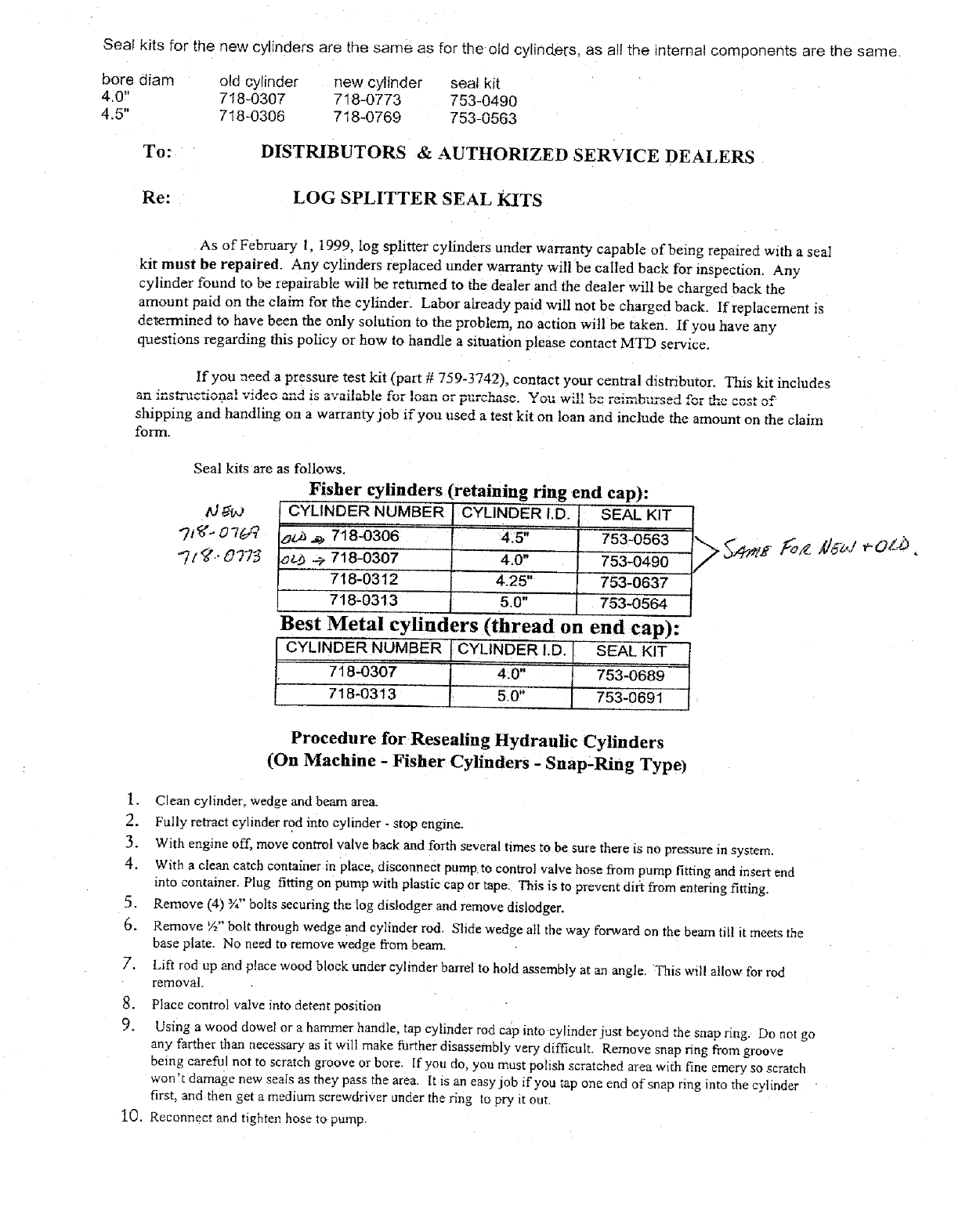

Seal kits for the new cylinders are the same as for the old cy ind.ers_as a!l me internal components are the same,

bore diam old cylinder new c_inder sealkit

4,0" 718-0307 718-0773 753-0490

4.5" 718-0306 718-0769 753-0563

To; ¸

DISTRIBUTORS & AUTHORIZED SERVICE DEALERS

Re: LOG SPLITTER SEAL KITS

As of February 1. 1999. log splitter cylinders under warranty capable of being repmred with a seal

kit must be repaired. Any cylinders replaced under warranty will be called back for inspection. Any

cylinder found to be repairable will be returned to the dealer and the dealer will be charged back the

amount paid on the claim for the cylinder. Labor already paid will not be charged back. If replacement is

determined to have been the only solution to the problem, no action will be taken. If you have any

questions regarding this policy or how to handle a situation please contact MTD service.

If you need a pressure test kit (part # 759-3742), contact your central distributor. This kit includes

an ins,_"uc=ional video and is a,:ailable for loan or purchase. You will be rei_b'arsed for t_hc cost of

shipping and handling on a warranty job if you used a test kit on loan and include the amount on the claim

form.

Seal kits are as follows.

Fisher cylinders (retaining ring end cap):

Md_J CYLINDER NUMBER CYLINDER I.D. SEAL KIT

_z._,...>718-0306

_zb-e 718-0307

718-0312

718-0313

4.5"

4.0"

4.25"

5.0"

753-0563

753-0490

753-0637

75320564

Best Metal cylinders (thread on end cap):

CYL NDER NOMBER [ CYLINDER I.D. SEAL KIT

718-0307 [ 4.0" 753-0689

718-03'13 ! 5.0 _'' 753-0691

Procedure for Resealing Hydraulic Cylinders

(On Machine - Fisher Cylinders - Snap-Ring Type)

1. Clean cylinder, wedge and beam area.

2. Fully retract cylinder rod into cylinder - stop engine.

3. With engine off, move control valve back and forth several times to be sure there is no pressure in system.

4. With a clean catch container in place, disconnect pump to control valve hose from pump fitting and in_ert end

into container. Plug fitting on pump with plastic cap or tape. This is to prevent dirt from entering fitting,

5. Remove (4) ¥I" bolts securing the log dislodger and remove dislodger.

6, Remove %" bolt through wedge and cylinder rod. Slide wedge all the way forward on the beam till it meets the

base plate. No need to remove wedge from beam,

Z. Lift rod up and place wood block under cylinder barrel to hold assembly at an angle, This will allow for rod

removal

8. Place control valve into detent position

9, Using a wood dowel or a hammer handle, tap cylinder rod cap into cylinder just beyond the snap ring. Do not go

any farther than necessary as it will make further disassembly very dit_cult. Remove snap ring from groove

being careful not to scratch groove or bore. If you do, you must polish scratched area with fine emery so scratch

won't damage new seals as they pass the area It is an easy job if you tap one end of snap ring into the cylinder

first, and then get a medium screwdriver under the ring to pry it our.

10. Reconnect and tighten hose to pump.