Pi

Sharp

of

Torque

Wrenctl

Allen

Screws

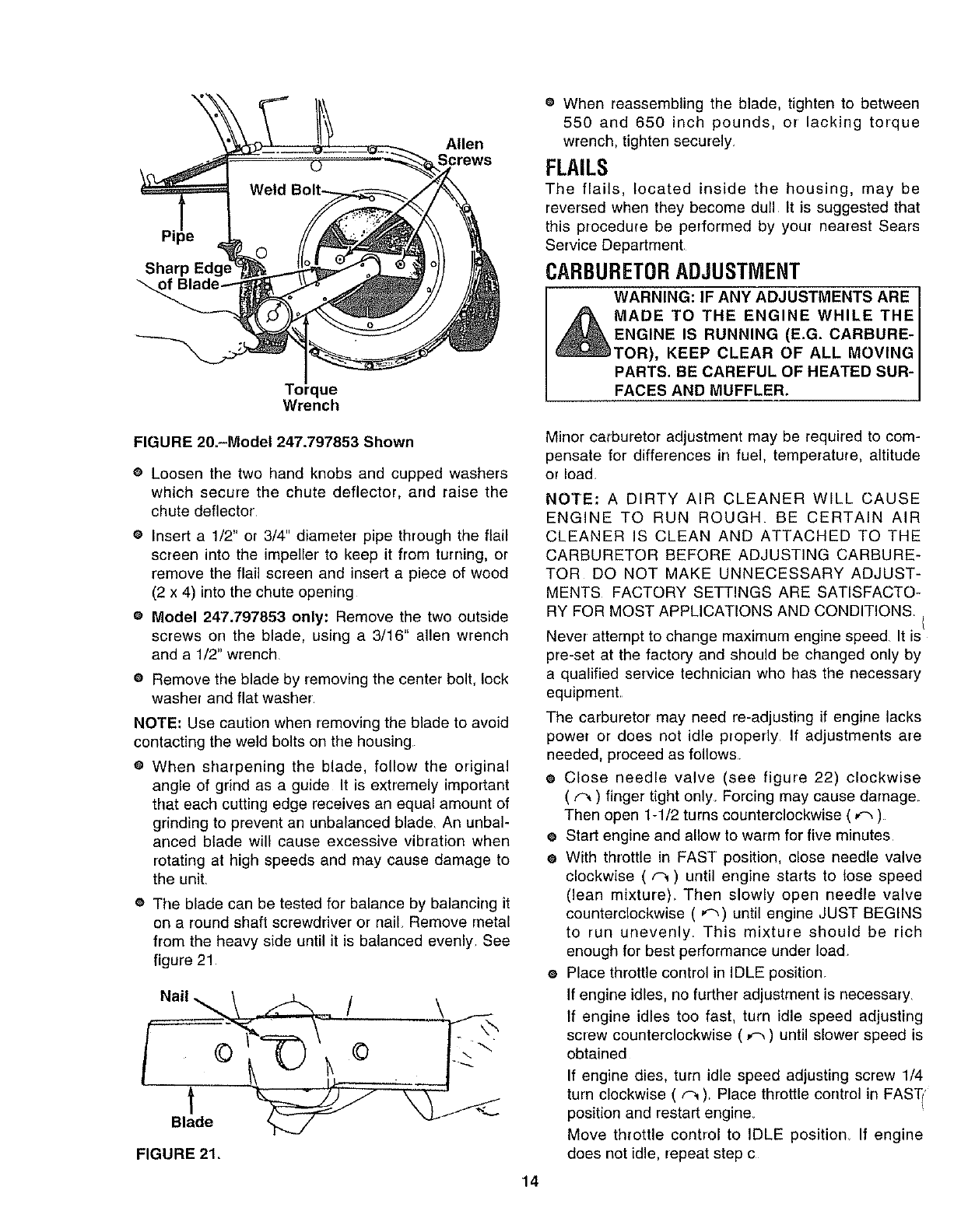

e When reassembling the blade, tighten to between

550 and 650 inch pounds, or lacking torque

wrench, tighten securely

FLAILS

The flails, located inside the housing, may be

reversed when they become dull It is suggested that

this procedure be performed by your nearest Sears

Service Department

CARBURETORADJUSTMENT

WARNING: IF ANY ADJUSTMENTS ARE

MAUE TO THE ENGINE WHILE THE

ENGINE IS RUNNING (E.G. CARBURE-

TOR), KEEP CLEAR OF ALL MOVING

PARTS. BE CAREFUL OF HEATED SUR-

FACES AND MUFFLER.

FIGURE 2O,-Model 247.797853 Shown

e Loosen the two hand knobs and cupped washers

which secure the chute deflector, arrd raise the

chute deflector

e Insert a 1/2" or 3/4" diameter pipe through the flail

screen into the impeller to keep it from turning, or

remove the flail screen and insert a piece of wood

(2 x 4) into the chute opening

e Model 247.797853 only: Remove the two outside

screws on the blade, using a 3/16" allen wrench

and a 1/2" wrench

e Remove the blade by removing the center bolt, lock

washer and flat washer

NOTE: Use caution when removing the blade to avoid

contacting the weld bolts on the housing

e When sharpening the blade, follow the original

angle of grind as a guide It is extremely important

that each cutting edge receives an equal amount of

grinding to prevent an unbalanced blade. An unbal-

anced blade will cause excessive vibration when

rotating at high speeds and may cause damage to

the unit.

e The blade can be tested for balance by balancing it

on a round shaft screwdriver or nail Remove metal

from the heavy side until it is balanced evenly See

figure 21

Na. \ /

f ,,

/

Bl!de '__1" --_j_

FIGURE 21,

Minor carburetor adjustment may be required to com-

pensate for differences in fuel, temperature, altitude

or load

NOTE: A DIRTY AIR CLEANER WILL CAUSE

ENGINE TO RUN ROUGH BE CERTAIN AIR

CLEANER IS CLEAN AND ATTACHED TO THE

CARBURETOR BEFORE ADJUSTING CARBURE-

TOR DO NOT MAKE UNNECESSARY ADJUST-

MENTS FACTORY SETTINGS ARE SATISFACTO-

RY FOR MOST APPLICATIONS AND CONDITIONS.

/

Never attempt to change maximum engine speed It is

pre-set at the factory and should be changed only by

a qualified service technician who has the necessary

equipment

The carburetor may need re-adjusting if engine lacks

power or does not idle properly If adjustments are

needed, proceed as follows

e Close needle valve (see figure 22) clockwise

( f-* ) finger tight only. Forcing may cause damage

Then open 1-1/2 turns counterclockwise ( _ )

e Start engine and allow to warm for five minutes

e With throttle in FAST position, close needle valve

clockwise ( ,_ ) until engine starts to lose speed

(lean mixture) Then slowly open needle valve

counterclockwise (f',) until engine JUST BEGINS

to run unevenly This mixture should be rich

enough for best performance under load.

e Place throttle control in IDLE position

If engine idles, no further adjustment is necessary

If engine idles too fast, turn idle speed adjusting

screw counterclockwise ( _ ) until slower speed is

obtained

If engine dies, turn idle speed adjusting screw 1/4

turn clockwise ( ,_ ). Place throttle control in FAS]_'

position and restart engine

Move throttle control to IDLE position_ If engine

does not idle, repeat step c

14