No

1/2" Diameter

FIGURE 12.

e To lower the hopper assembly, use one hand to

grasp the handle at the top of the hopper assembly

and lift slightly, Pull up on the release bar, and

lower the hopper assembly to the ground Release

the bar'. See figure 13.

Hopper

Assembly

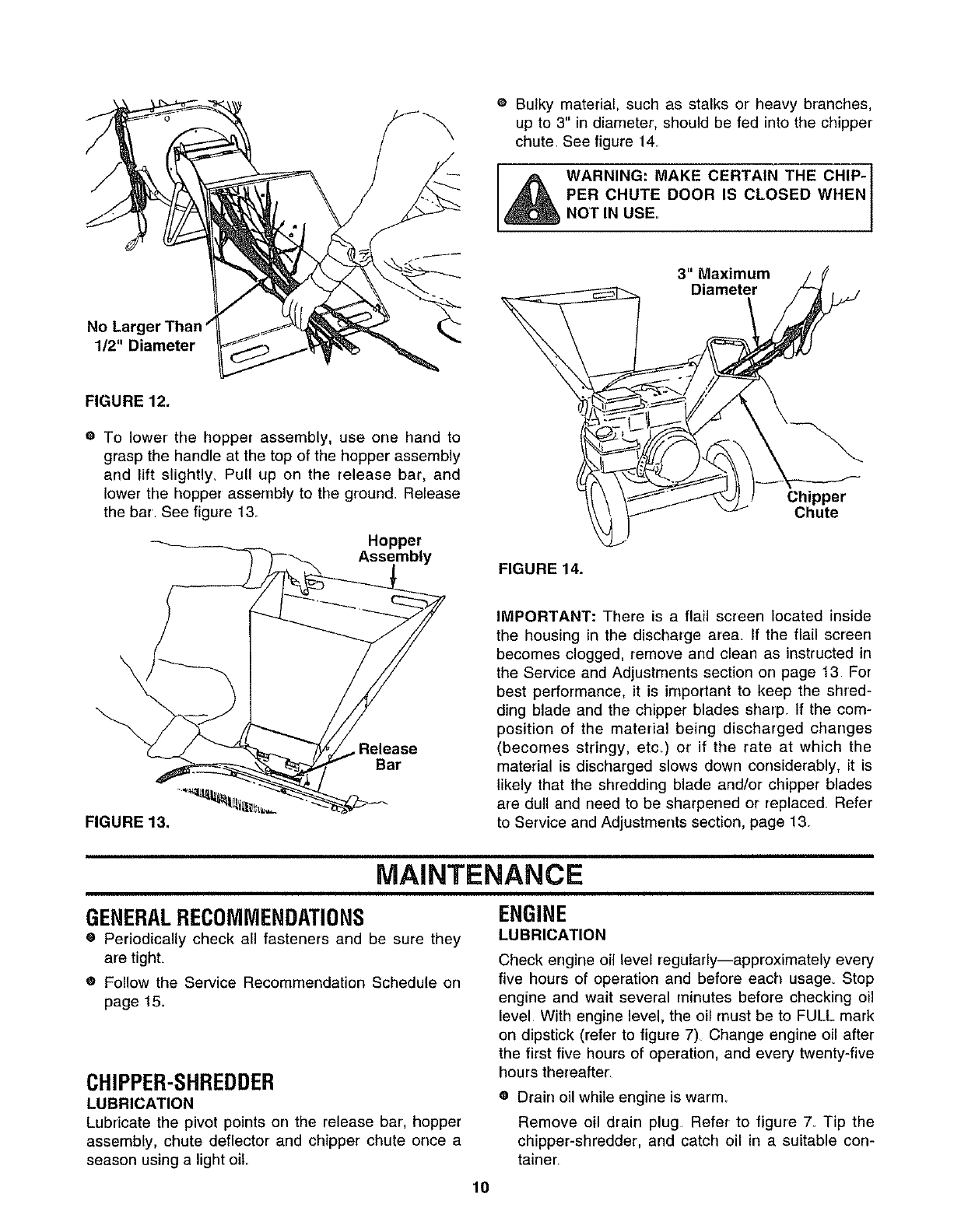

e Bulky material, such as stalks or heavy branches,

up to 3" in diameter, should be fed into the chipper

chute See figure 14

WARNING: MAKE CERTAIN THE CHIP-

PER CHUTE DOOR IS CLOSED WHEN

NOTINUSE.

3"Maximum

Diame_r

Chipper

Chute

FIGURE 14.

FIGURE 13.

Release

Bar

IMPORTANT: There is a flail screen located inside

the housing in the discharge area If the flail screen

becomes clogged, remove and clean as instructed in

the Service and Adjustments section on page 13 For

best performance, it is important to keep the shred-

ding blade and the chipper blades sharp If the com-

position of the material being discharged changes

(becomes stringy, etc) or if the rate at which the

material is discharged slows down considerably, it is

likely that the shredding blade and/or chipper blades

are dull and need to be sharpened or replaced, Refer

to Service and Adjustments section, page 13.

MAINTENANCE

GENERALRECOMMENDATIONS

• Periodically check all fastener's and be sure they

are tight.

® Follow the Service Recommendation Schedule on

page 15.

CHIPPER-SHREDDER

LUBRICATION

Lubricate the pivot points on the release bar, hopper

assembly, chute deflector and chipper chute once a

season using a light off

ENGINE

LUBRICATION

Check engine oil level regularly--approximately every

five hours of operation and before each usage. Stop

engine and wait several minutes before checking oil

level With engine level, the oil must be to FULL mark

on dipstick (refer to figure 7). Change engine oil after

the first five hours of operation, and every twenty-five

hours thereafter

• Drain oil while engine is warm.

Remove oil drain plug. Refer to figure 7_ Tip the

chipper-shredder, and catch oil ir} a suitable con-

tainer

10