Check Transmission Gear Oil

Checkthetransmissiongearoilafterevery30 hoursofoperation

orwheneveryounoticeanyoil leak.Operatingthe tillerwhenthe

transmissionis lowon oilcan resultin severedamage.

ToChecktheTransmissionGearOil Level:

1. Checkthegearoil levelwhenthetransmissionis cool.Gearoil

willexpandinwarmoperatingtemperaturesandthis expansion

willprovidean incorrectoil levelreading.

2. Withthetilleron levelground,pullthe DepthRegulatorLeverall

thewayup.

3. Removetheoil fillplugfromthetransmissionhousingand look

insidetheoilfillholeto locatethemaindriveshaftsituatedbelow

thehole.SeeFigure21.

4. Thegearoil leveliscorrectifthegearoilis approximatelyhalfway

uptheside ofthe maindriveshaft.

5. If thegearoil levelislow,add gearoil asdescribednext.Ifthe

gearoillevelisokay,securelyreplacethe oil fillplug.

6. If addingonlya fewouncesofgearoil, useAPI ratedGb4 or

Gb5 gearoil havinga viscosityofSAE 140,SAE85W-140or SAE

80W-90.Ifrefillinganemptytransmission,useonly Gb4 gearoil

havinga viscosityd SAE85W-140or SAE140.

7. Whilecheckingfrequentlytoavoidoverfilling,slowlyaddgearoil

intotheoilfill holeuntilit reachesthe halfwaypointon thedrive

shaft.

8. Securelyreplacetheoil fillplug.

Change Transmission Gear Oil

Thetransmissiongearoildoesnot needtobe changedunlessit has

beencontaminatedwithdirt, sandor metalparticles.Seeanautho-

rizedSearsServiceCentertohavethetransmissiongearoil changed

orto scheduleservice,simplycontactSearsat1-800-4-MY-HOME®.

LUBRICATION

Afterevery10operatinghours,oilor greasethelubricationpoints.Use

cleanlubricatingoil (#30weightmotoroil is suitable)andcleangeneral

purposegrease(greasecontaininga metallubricantis preferred,if

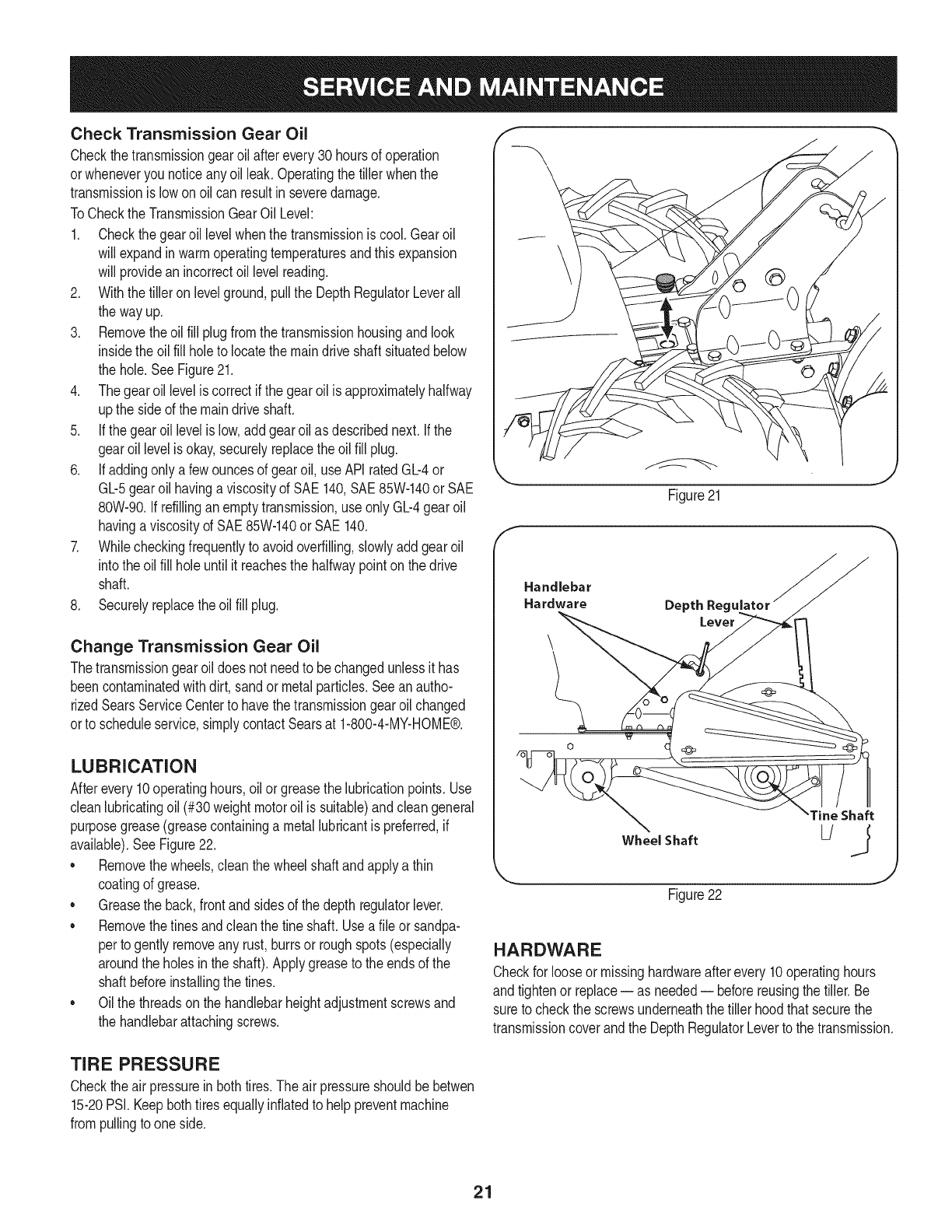

available).SeeFigure22.

• Removethewheels,cleanthewheelshaftandapplya thin

coatingofgrease.

• Greasetheback,frontandsidesofthe depthregulatorlever.

• Removethetinesandcleanthefine shaft.Usea fileor sandpa-

pertogentlyremoveany rust,burrsor roughspots(especially

aroundtheholesintheshaft).Applygreasetotheendsofthe

shaftbeforeinstallingthetines.

• Oilthe threadsonthehandlebarheightadjustmentscrewsand

thehandlebarattachingscrews.

\

Figure21

Handlebar

Hardware Depth Reg_

Wheel Shaft

Figure22

TineShaft

J

HARDWARE

Checkforlooseor missinghardwareafterevery10operatinghours

andtightenor replace= asneeded-- beforereusingthetiller.Be

suretocheckthescrewsunderneaththe tillerhoodthat securethe

transmissioncoverandthe DepthRegulatorLevertothe transmission.

TIRE PRESSURE

Checktheair pressurein bothtires.Theairpressureshouldbe betwen

15-20PSi.Keepbothtiresequallyinflatedto helppreventmachine

frompullingtooneside.

21