4-- 5

T -343

4.4.10 Lube Oil Filter

The primary oil filter is located near the radiator fan

(see Figure 1-4).

1. After warming up the engine, stop engine, remove

drain plug fromoil reservoir anddrain enginelube oil.

2. Replace filters. Lightly oil gasket on filter before

installing.

3. Add lube oil (Refer to paragraph 1.10.f).

4. Warm up engine and check for leaks.

4.4.11 Engine Speed

The engine speed is electronically controlled. DO NOT

ATTEMPT TO ADJUST ENGINE SPEED.

4.4.12 Replacing the Engine Speed Sensor

1. Disconnect the plug to the sensor .

2. Remove the bolt securing the sensor to the housing.

3. Remove the sensor from the housing.

4. Clean the recess in the housing to ensure that the

sensor seats properly when re-installed.

5. Re-install by sensor , replace the securing bolt and

connect the plug to the sensor.

4.4.13 Engine Air Cleaner

a. Inspection

The d ry element or oil bath air cleaner should be

inspected regularly for leaks. A damaged air cleaner or

hose can s eriously affect the performance andlife of the

engine. The air cleaner is designed to effectively

remove contaminants from the air stream entering the

engine. An excessive ac cumulation of these

contaminants in the air cleaner will impair its operation.

Therefore, a service schedule must be set up and

followed.

1. Check all connections for mechanical tightness. Be

sure the air cleaner outlet pipe is not fractured.

2. In c ase ofleakage andif adjustment does notcorrect

the trouble, replace necessary parts or gaskets.

Swollen or distorted gaskets must always be

replaced.

b. Air Filter Indicator

The air filter indicator is mounted on the unit frame and

connected to the engine air intake. Its function is to

indicate when the air cleaner element requires

replacing. In operation: When a plugged air cleaner

decreases intake manifold pressure to 500 mm (20”)

WG, the indicator moves to the red line. The air cleaner

element should be replaced and the indicator reset by

pressing the reset button.

c. ServiceProcedure(DryElement)

1. Stop the engine, remove air c leaner and install a

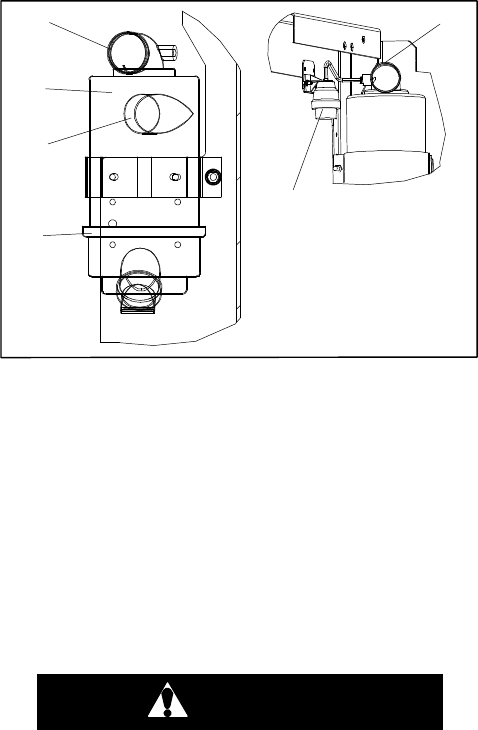

new element. Refer to Figure 4-3.

5

4

2

1

1

3

1. Air Outlet

2. Air Cleaner Body

3. Air Inlet

4. Cap Clamp

5. Air Filter Indicator

Figure 4-3 Air Filter (Dry Element Type)

d. Service Procedure (Oil Type)

Inspect the oil cup (see Figure 4-4) at regular intervals.

Initially, inspect daily or as often as conditions require.

Never allow more than1/2 inch (12.7 mm) of dir tdeposit

in the c up. More than 1/2 inch accumulation could result

in oil and dirt carrying over into the engine, causing

accelerated engine wear. Heavily contaminated oil will

not allow the air cleaner to function properly.

CAUTION

Alwayscovertheengineinlettube whilethe

air cleaner is being serviced.

Stop the engine and remove the oil cup from the air

cleaner . Dispose of the oil in an environmentally safe

manner . Remove the inner cup from the oil cup and

clean both cups.

Reassemble and fill both oil cups to the indicated level

with oil specified in paragraph 1.10.f.