4-- 6T--343

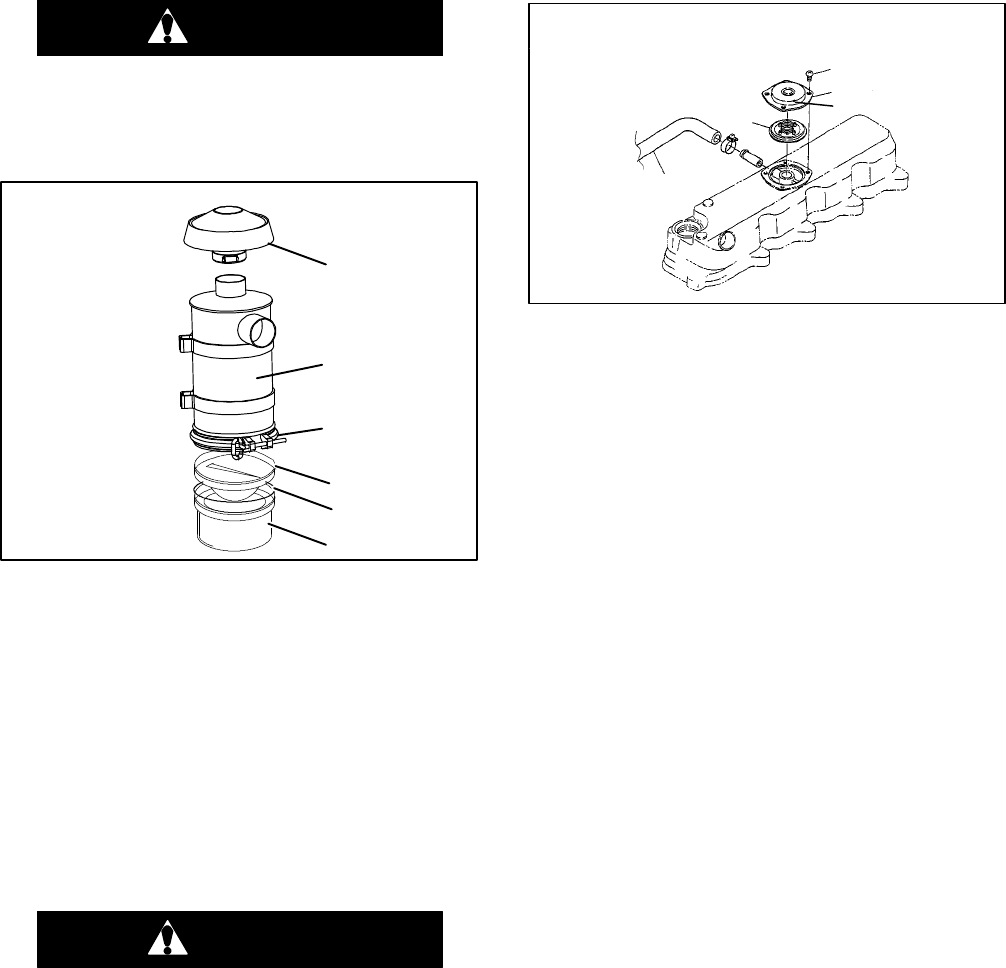

CAUTION

Do not underfill oroverfill theoil bath cups.

Overfilling of cups causes loss of capacity;

underfilling cups causes lack of filtering

efficiency.

1

2

3

4

5

6

1. Air Inlet Hood

2. Air Cleaner Body

3. Cap Clamp

4. Inner Oil Cup

5. Gasket

6. Oil Cup

Figure 4-4 Air Filter (Oil Bath Type)

e. Service - Body Assembly

The lower portion of the air cleaner should be inspected

each time the oil cup is inspected or serviced. If there is

any sign of contaminant buildup or plugging, the body

assembly should be removed and back flushed.

At leastoncea year orat regular engineservice per iods,

remove the entire air cleaner and per form the following:

1. Remove oil cups. Check and clean center tube.

WARNING

Do not use gasoline to clean air cleaner

parts.

2. Pump solvent through the air outlet with sufficient

force andvolumeto produce ahard, even s tream out

of the bottom of the body assembly. Reverse flush

until all foreign material is removed.

4.4.14 Engine Crankcase Breather

The engine uses a closed type breather with the

breather line attached to the cylinder head cover (see

Figure 4-5). It is not necessary to dissemble valve style

elements for cleaning. However , the bleed hole should

be checked to ensure it is free of obstruction. Check

once a year or at every 3,000 hours maintenance

interval, whichever comes first.

1

5

4

3

2

1. Scre

w

2. Breather Cover

3. Bleed Hole

4. Breather

V

alve

5. Breather Tube

Figure 4-5 Engine Crankcase Breather

4.4.15 Servicing Intake Heater

1. Remove harness connection from heater.

2. Remove intake transition mounting hardware.

3. Remove intake transition, heater and both gaskets.

4. Clean old gasket material o f f the transition and

manifold mounting services.

5. Install new heater with a new gasket on either side.

6. Assemble transition to heater and torque mounting

hardware (refer to the engine manual for torque

values).

7. Reconnect harness to heater connection point.

8. Coat stud on heater with protective coating.

4.5 SERVICING THE ALTERNATING CURRENT

GENERATOR

4.5.1 Preventative Maintenance and

Operating Precautions

Costly repairs and down time can usually be prevented

by operating electrical equipment under conditions that

are compatible with those under which the equipment

was designed. Follow the instructions outlined below to

insure maximum efficiency of the electrical equipment.

a. Cooling

Keep all cooling parts clean. DO NOT EXCEED

TEMPERATURE RISE OF 80C (176F) ABOVE A 40C

(104F) AMBIENT. This ensures that the NEMA Class

“F” insulation will not be damaged. DO NOT EXCEED

RATED LOAD except as specified for the equipment.

OPERATE GENERATOR AT RATED SPEED. Failure

to operate generators at rated load or speed will cause

overheating and possible damage to windings due to

over voltage or current.