2-- 3

T -343

2.3 STARTING AND STOPPING INSTRUCTIONS

2.3.1 Pre-Start Inspection

a. Check engine lubrication and fuel filters, oil lines, and

connections for leaks. If required, tighten connec-

tions and/or replace gaskets.

b. Check engine lubricating oil level. (Refer to para-

graph 1.10, table entry f.)

c. Check polyV-belt forfraying orcracksand properten-

sion. (Refer to paragraph 4.4.9).

d. Check radiator hoses for leaks and check r adiator

coolant level. (Refer to paragraph 1.10, table entry j.)

e. Checkradiator coiland generator airintakescreen for

cleanliness. If required, clean using compressed air,

reversing the normal air flow.

f. Check air cleaner for cleanliness and clean if neces-

sary. (Refer to paragraph 4.4.13.)

g. Check in--line fuel filter and clean if necessary. (Refer

to paragraph 4.4.4.)

h. Drain water from fuel tank sump and filter bowl.

i. Fillfueltank withdiesel fuel.(Refer toparagraph1.10,

table entry g.)

j. Check air intake heater amperage. (Refer to para-

graph 1.10, table entry h.)

k. Check battery terminals for cleanliness and secure-

ness. If required,clean, thencoat witha battery termi-

nal sealant.

l. Check, and if required, tighten all electrical connec-

tions.

m.Check, and if required, tighten all hardware (brack-

ets, etc.).

n. Ensure that the main generator set circuit breaker is

off (CB-1 for 460 volt units or CB4 for 230 volt units).

Connect power cable to refrigeration unit and pro-

ceed to paragraph 2.3.2.

2.3.2 Starting Instructions

WARNING

Beware of moving poly V-belt, belt driven

components and hot exhaust components.

WARNING

Under no circumstances should ether or

any other unauthorized starting aids be

used inconjunctionwith theair intakeheat-

er.

NOTE

Piston rings in engines that have oper ated less

than 100 hours may not be fully seated. This

may lead to the possibility of oil seepage from

the exhaust pipe. To properly seat the r ings,op-

eratethe engineunderfullload foraperiodof 24

hours. If the condition persists, check valve

clearance w henthe engineis cold. (Refer toen-

gine workshop manual lis ted in paragraph 1.2).

a. Standard Units

1. Hold intake heater switch (see Figure 1-6) in the

PREHEAT position. Suggested hold times for a cold

engine are as follows:

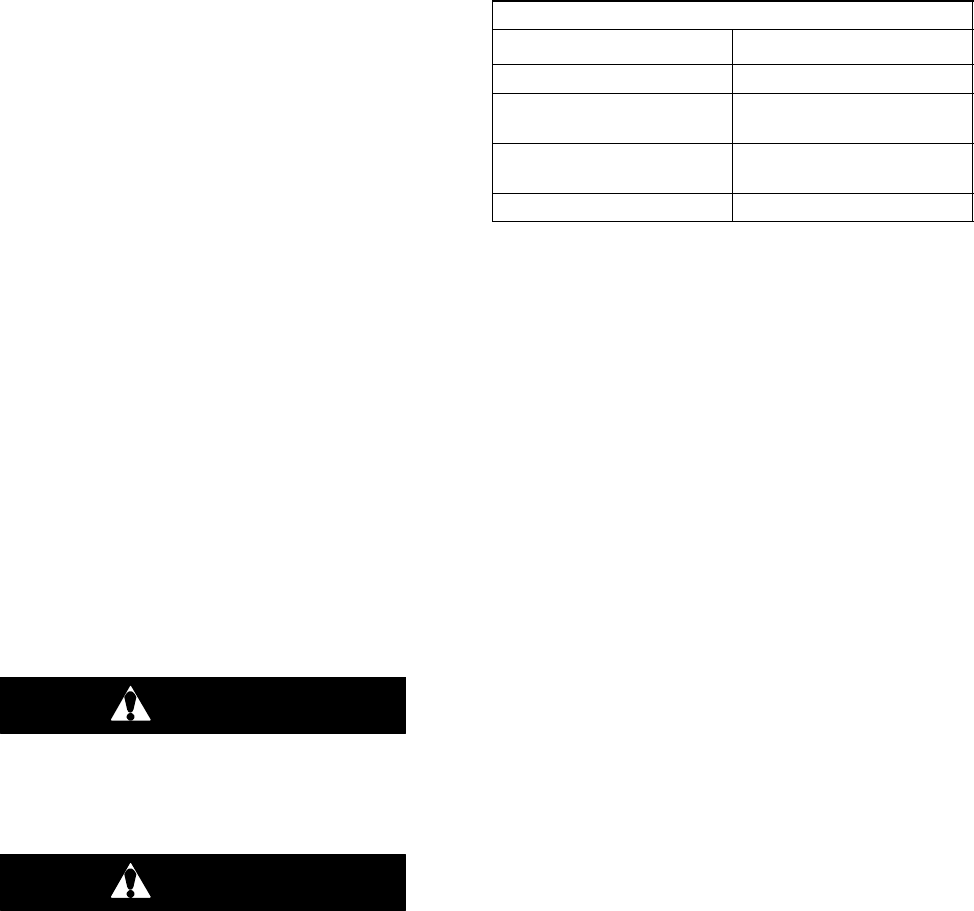

COLD ENGINE PREHEAT TIMES

Ambient Temperature Time

78 F/ 26 C 5 seconds

32Fto78F

(0Cto26C)

10 seconds

18Fto32F

(--8Cto26C)

20 seconds

Below18F/-8C 30 seconds

2. With the intake heater switch held in the PREHEAT

position, place the ignition switch in the START posi-

tion.

3. After the engine has started, continue to hold the in-

take heater switch inthe PREHEAT pos ition until the

engine develops sufficient oil pressure to close the

oil pressure safety switch (approximately 5

seconds). When released, the intake heater switch

will automatically return to the OFF position and the

heater will remain energized for 3 minutes.

b. Units with Auto Start

1. Place the Ignition switch (IGN) in the RUN position.

2. If the l ow coolant sensor (LCS) is immersed in cool-

ant, the auto restart module will energize the heater

for 30 seconds and the safety buzzer will sound. Af-

ter the 30 second delay, the unit will attempt to start.

2.3.3 Post-Start Inspection

a. Turn on CB-1 for 460 volt units or CB4 for 230 volt

units.

b. Check generator output with a voltmeter. In the no

load condition, output should be at 490 ( +/- 10%)

volts with 1800 engine RPM. Place generator set

main circuit breaker in the ON position. Start refrig-

eration unit.

c. Run engine 10 minutes (check total time meter op-

eration).

d. Listen for abnormal bearing noise (AC generator).

e. Check fuel lines, lube oil lines, and filters for leaks.

f. Check exhaust system for leaks.

2.3.4 Stopping Instructions

Place the ignition switch in the OFF position.