SECTION I

INTRODUCTION AND DESCRIPTION

1-1 INTRODUCTION

We are pleased to have you as a Bush Hog cus-

tomer. Your Side Mount Rotary Cutter, Model

SM60,has been carefully designed to assure maxi-

mum service with minimum down time. This manual

is provided to give you the necessary operating and

maintenance instructions for keeping your rotary cut-

ter in top operating condition. Please read this man-

ual thoroughly. Understand what each control is for

and how to use it. Observe all safety precautions

decaled on the machine and noted throughout the

manual to insure safe operation of the equipment. If

any assistance or additional information is needed,

contact your local authorized Bush Hog dealer.

1-2 DESCRIPTION

The Side Mount Rotary Cutter (Fig. 1-1) is an agri-

cultural implement designed primarily for cutting

brush up to 1 inch (2.5cm) in diameter along ditches

and banks. It is to be used on tractors weighing

a minimum of 6000 lbs. (2722 kg) not including

ballast and having a minimum of 50 PTO horse-

power. Two models are available; the model

SM60R, requiring 540 rpm PTO speed and the

model SM160R, requiring a 1000 rpm PTO speed.

Front and rear discharge shields are standard on

each.

The cutter is all hydraulically powered as shown in

Fig. 1-2. A hydraulic gear pump is driven by the

tractor PTO. The 35 gallons of oil are delivered to

the motor at a maximum of 3200 PSI on a cast

iron pump and motor. The hydraulic oil is filtered

by a suction strainer mounted inside the tank and a

canister type return line filter. Each filter is equipped

with a bypass to prevent pumpt cavitation, should it

become clogged. Slide cylinder and deck pivot

cylinders are controlled by the tractor auxiliary

hydraulic system.

6

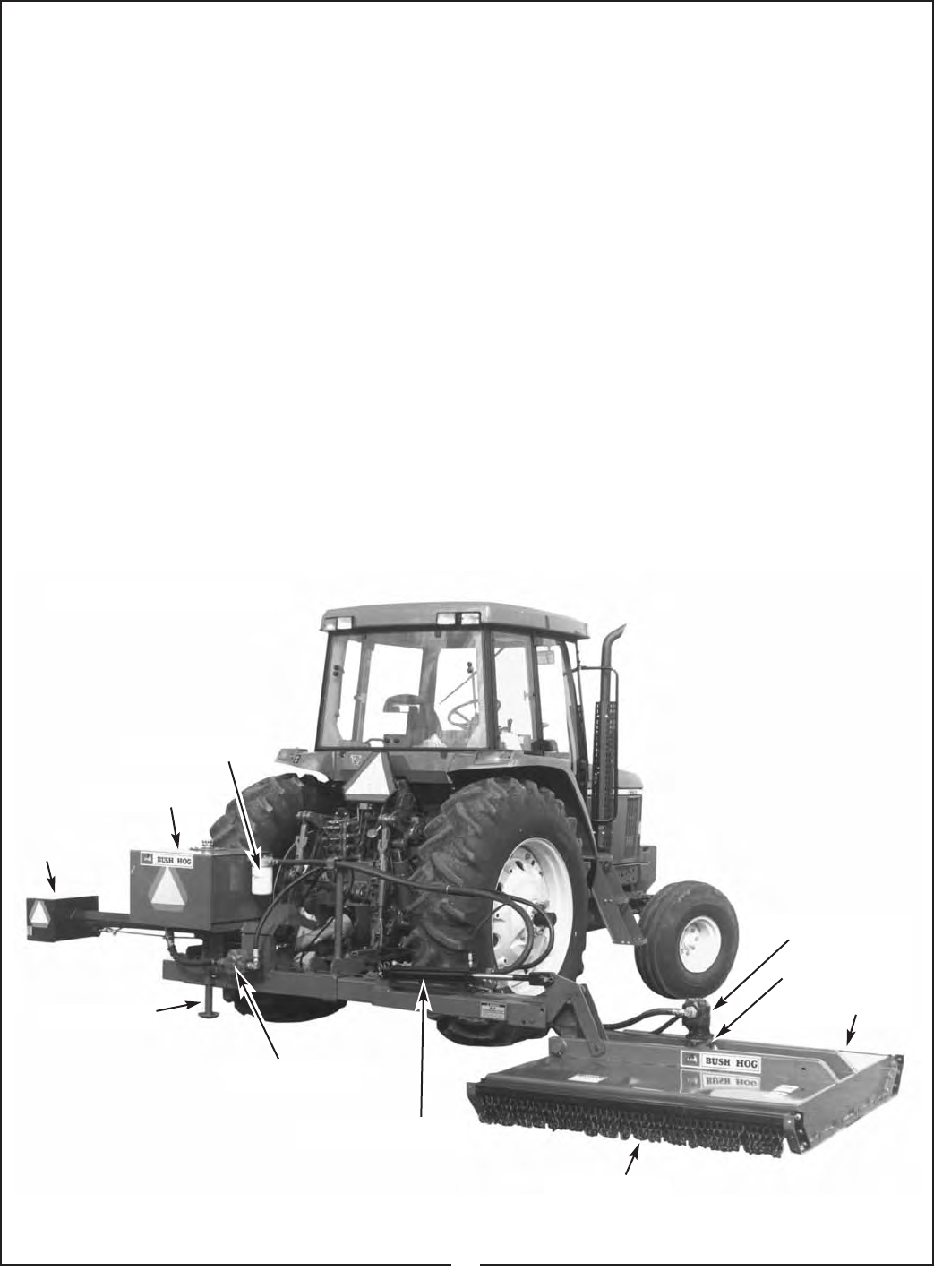

Return Line Filter

Hydraulic Tank

Counterweight

Box

Hydraulic Pump

Parking Stand

Figure 1-1 Major Components

Head Pivot Cylinder

Safety Chains

Hydraulic Motor

Spindle Housing

Cutter Deck