F. Pull driveline apart. Attach the outer (female)

section to the tractor PTO shaft and the inner (male)

section to the pump input shaft. Pull on each drive-

line section to make sure yokes lock into place.

G. Hold driveline sections parallel to each other to

determine if driveline is too long. (Fig. 2-4) If drive-

line must be shortened, perform steps “D”

through “H” in paragraph 2-2.

H. Position implement at point with greatest dis-

tance between pump input shaft and PTO shaft.

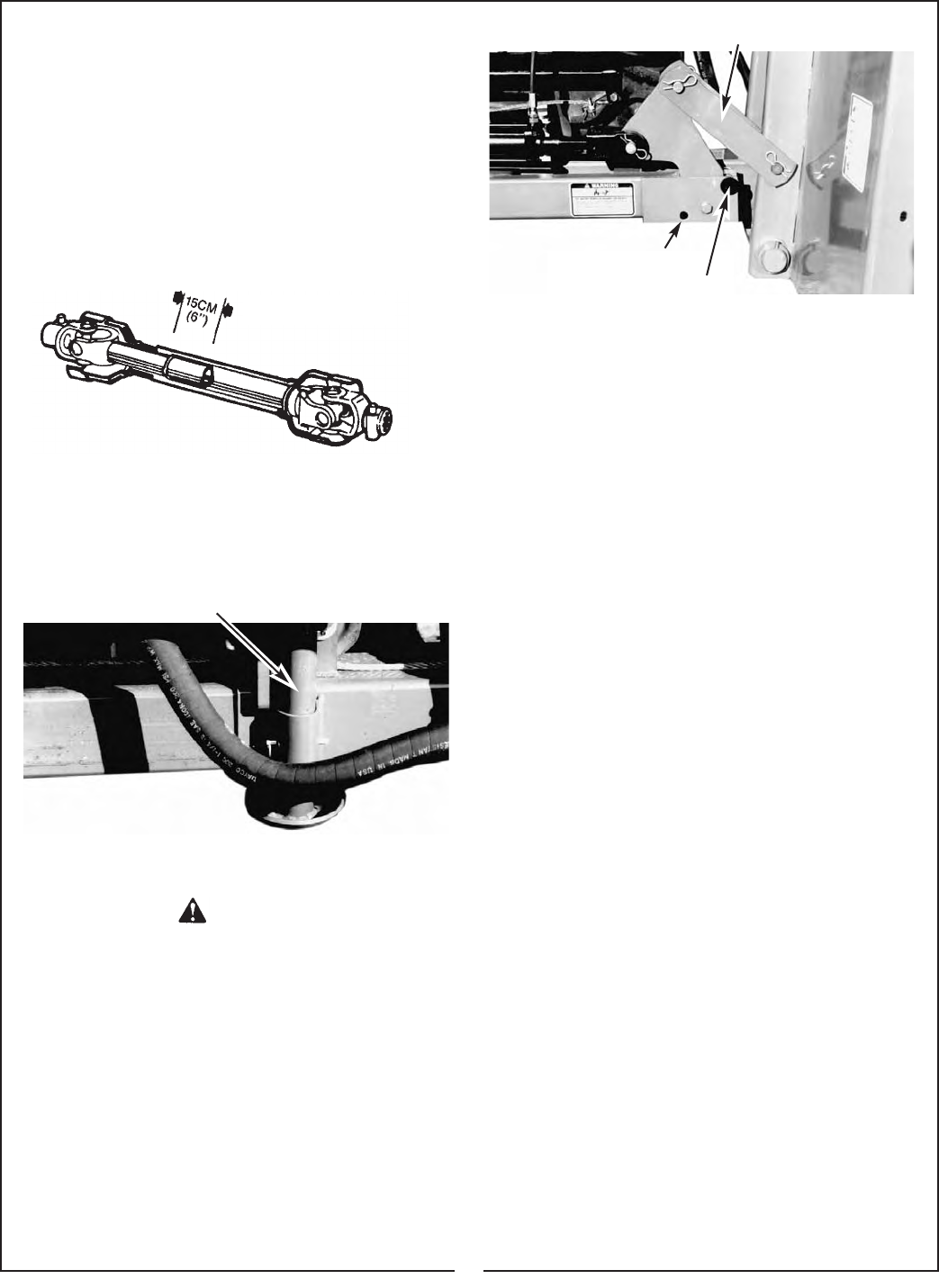

I. Hold driveline halves parallel to each other

and check for minimum of 6 inches (15 cm) over-

lap. (Fig. 2-1)

J. Apply multi-purpose grease to inside of outer

(female) driveline section. Assemble driveline and

install on machine and implement. Pull on each driv-

eline section to make sure yokes lock into place.

K. Raise implement off ground. Pin parking stand

in the up position. (Fig. 2-2)

Figure 2-2 Parking Stand In Up Position

L. Remove transport lock pin located at deck pivot

linkage and insert into storage holes. (Fig. 2-3)

STAY CLEAR OF DECK DURING AND AFTER

REMOVAL OF LOCK PIN. AIR INHYDRAULIC

LINES COULD ALLOW CUTTER DECK TO

FALL, CAUSING POSSIBLE INJURY.

M. Position cutter deck straight out (parallel to

ground) and approximately 2 inches (51 mm) from

ground.

N. Adjust cutter deck front to rear using top link of

3-point hitch. Rear of cutter deck should be 1-2

inches (25-51 mm) higher than front.

O. Adjust lower 3-point hitch arms to level cutter

deck sliding beam right to left.

P. Adjust 3-point hitch position control to stop at

present height. This will prevent accidental dragging

of sliding beam.

WARNING

Fig. 2-3 Pivot Linkage

Q. If equipped with optional valve stand, adjust to

desired working position.

R. Raise cutter deck and install transport lock pin

before traveling. (Fig. 2-3)

NOTE

It is recommended that front end ballast

(weights) be added to tractor for stabilization. In

some uses, added stabilization may be gained

by weighting left rear wheel heavier than right

rear wheel. Do not exceed tractor ballast rating.

Consult your tractor dealer.

2-2 DRIVELINE MODIFICATION

IMPORTANT

IT IS EXTREMELY IMPORTANT THAT DRIVELINE

MATCH THE TRACTOR BEING USED. IF UNIT IS

ATTACHED ON ANOTHER TRACTOR, DRIVELINE

MUST BE CHECKED FOR CORRECT LENGTH.

FAILURE TO MATCH DRIVELINE TO TRACTOR

WILL CAUSE FAILURE TO THE PUMP.

Due to the many variations in tractor/implement

hitch points and corresponding differences in dis-

tances between tractor PTO shafts and implement

input shafts, drivelines may need to be shortened as

follows:

A. Attach implement to tractor 3-point hitch.

B. Raise and lower implement to determine the

shortest distance between the tractor PTO shaft and

the pump input shaft. Stop tractor leaving imple-

ment in position of shortest distance. Block imple-

ment in position.

C. Pull driveline apart. Attach the outer (female)

section to the tractor PTO shaft and the inner (male)

section to the pump input shaft. Pull on each drive-

line section to make sure yokes lock into place.

D. Hold driveline halves parallel to each other to

determine amount to be removed. Measure approxi-

mately 3 in. (76 mm) back from the opposite univer-

sal joint shield and mark the free end of the shield.

Do this for each section. (Fig. 2-4)

E. Clamp the end of driveline in a vice. Cut off

shield at point it was marked.

F. Using the cut off section of shield as a guide,

cut the shaft the same amount. (Fig. 2-6)

8

Overlap Minimum

Figure 2-1

Pin Storage Hole

Transport Lock Pin