8

26-7/8”

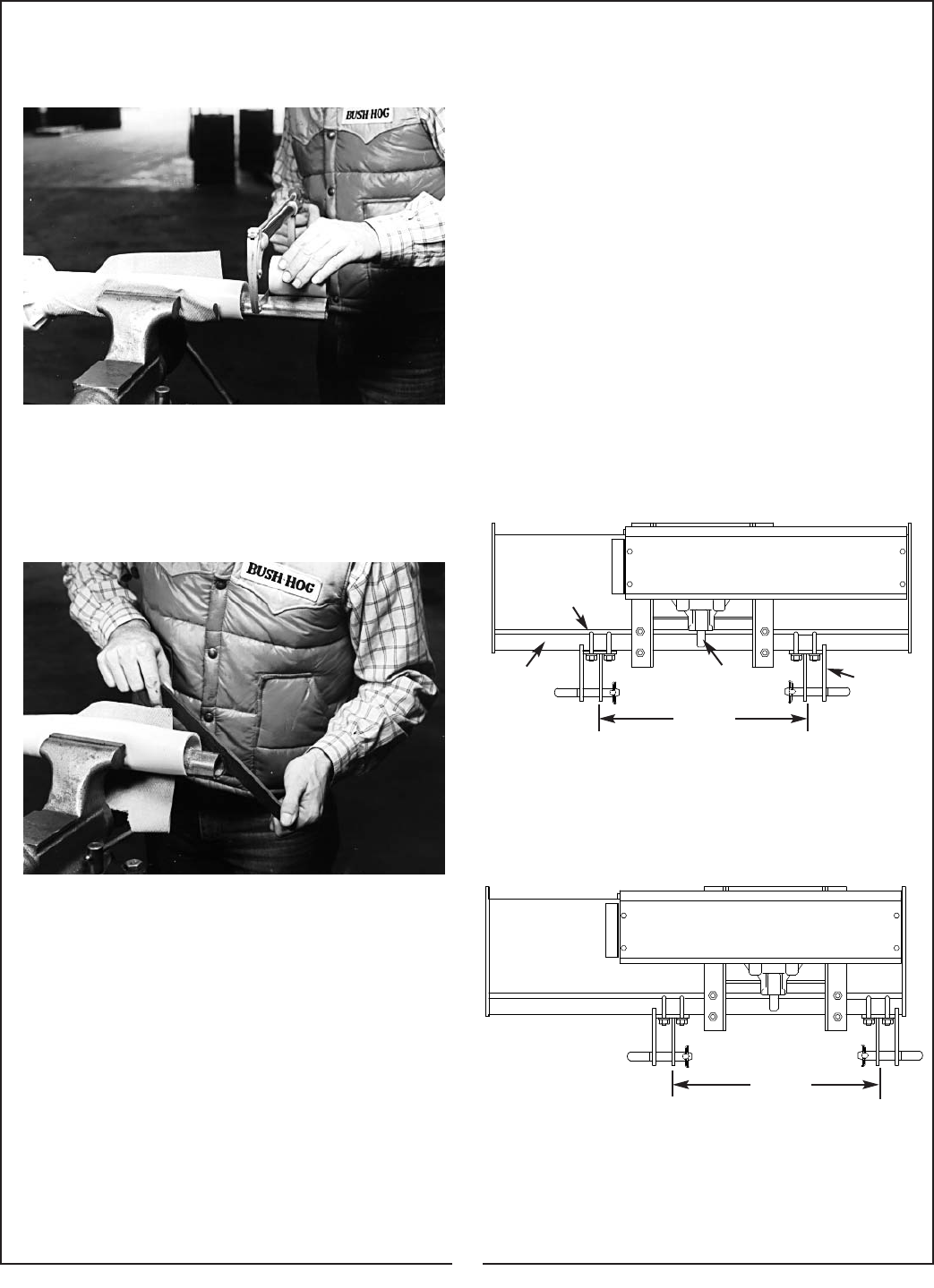

Figure 2-7 Alternate Hitch Lug Mounting

Figure 2-6 Hitch Lug Dimension

Clamp

Bolts

Frame

Hitch Pin

Brackets

Gearbox

Input Shaft

26-7/8”

H. Using cut off section of shield as a guide, cut

shaft the same amount. (Figure 2-4)

Figure 2-4

I. Repeat steps “G” and “H” to other driveline

section.

J. Deburr ends of driveline sections and clean

away all chips and fillings. (Figure 2-5)

Figure 2-5

K. Apply multi-purpose grease to inside of outer

(female) driveline section. Assemble driveline and

install on tractor and tiller. Pull on each driveline

section to be sure yokes lock into place. Make cer-

tain driveline shielding is in place and in good condi-

tion.

L. Adjust lower lift arm to level tiller right to left.

Refer to tractor operator’s manual for instructions.

M. Adjust top link of tractor 3-point hitch to level

tiller front to rear.

N. Set up tractor stabilizer bars, sway blocks, or

equivalent to prevent implement side sway.

2-2 OFFSETTING TILLER

The tillers may be offset to the right up to 6 inches on

Model RTS40, 12 inches on Models RTS50 and

RTS60, and 18-1/4 inches on Model RTS74. Adjust as

follows:

A. Loosen U-bolts securing hitch lugs and gearbox

stand to tiller frame.

B. Slide hitch lugs and gearbox to desired position

maintaining the distance shown in Figure 2-6. An addi-

tional 4-1/2 inches of offset can be obtained on the

RTS40 and RTS50 by reversing hitch lugs as shown in

Figure 2-7.

C. Tighten U-bolts.