11

(6)100 Hours

Fill Line

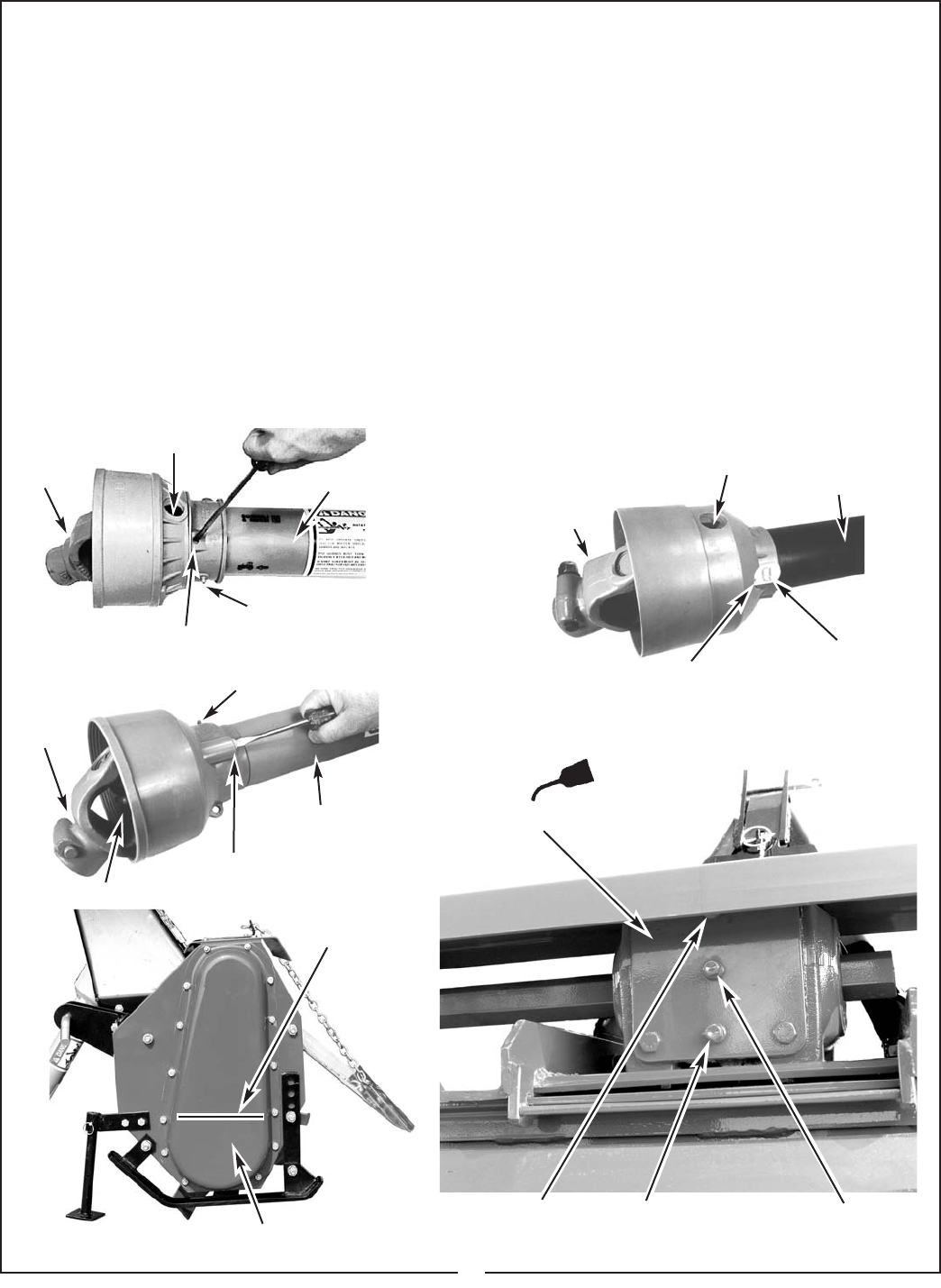

Figure 4-1A Lubrication

NOTE: In some instances, sliding the yoke

shield back will be necessary to conveniently

lubricate the cross bearings.

Bondioli & Pavesi Driveline

Binacchi Driveline

EG Driveline

(1) Before Each Use

(3) Before Each Use

(2) Before Each Use

To remove yoke shield, depress the three tabs with a screwdriver

and slide cover back.

(1) Before Each Use

(2) Before Each Use

(3) Before Each Use

To remove yoke shield, turn slotted head

180° with screwdriver, slide cover back.

(1) Before Each Use

(2) Before Each Use

(3) Before Each Use

To remove yoke shield,turn

slotted head 90° with

screwdriver, remove turn

screw and slide cover back.

(5) Before

Each Use

(5) Before

Each Use

(5) Before

Each Use

4-2 LUBRICATION (Figure 4-1)

NOTE

The multi-purpose grease referenced in this section

is an NLGI Grade 2 type grease.

BEFORE EACH USE

1. Driveline Universal Joints - Apply multi-purpose

grease with grease gun.

2. Driveline Guard - Apply 2-3 shots of multi-purpose

grease with grease gun to plastic fitting.

3. Driveline - Disconnect PTO driveline, pull the two

sections apart, apply thin coat of multi-purpose

grease to the outside of inner (male)

section.Reassemble sections and install.

Pull each section to be sure driveline and shields

are securely connected. Make certain PTO

shielding is in good condition.

4. Input Gearbox - Add EP80W-90 gear oil, if neces-

sary, to bring oil level to check plug. Gearbox

capacity is 27 ozs.

40 HOURS

5. Shearbolt Yoke - Apply multi-purpose grease to

grease fitting. This fitting must be kept lubricated

to prevent yoke from seizing.

100 HOURS

6. Chain Drive - Remove chain drive shield and

clean out old grease. If chain has one link or

more of slack, have an authorized Bush Hog

dealer resize the chain. Pack bottom of shield

with multi-purpose grease to the line shown in

Figure 4-1. Reinstall shield using new gasket.

Vented Fill Plug

(Under Shield)

Drain Plug

Oil Level

Check Plug

(4) Before Each Use