9

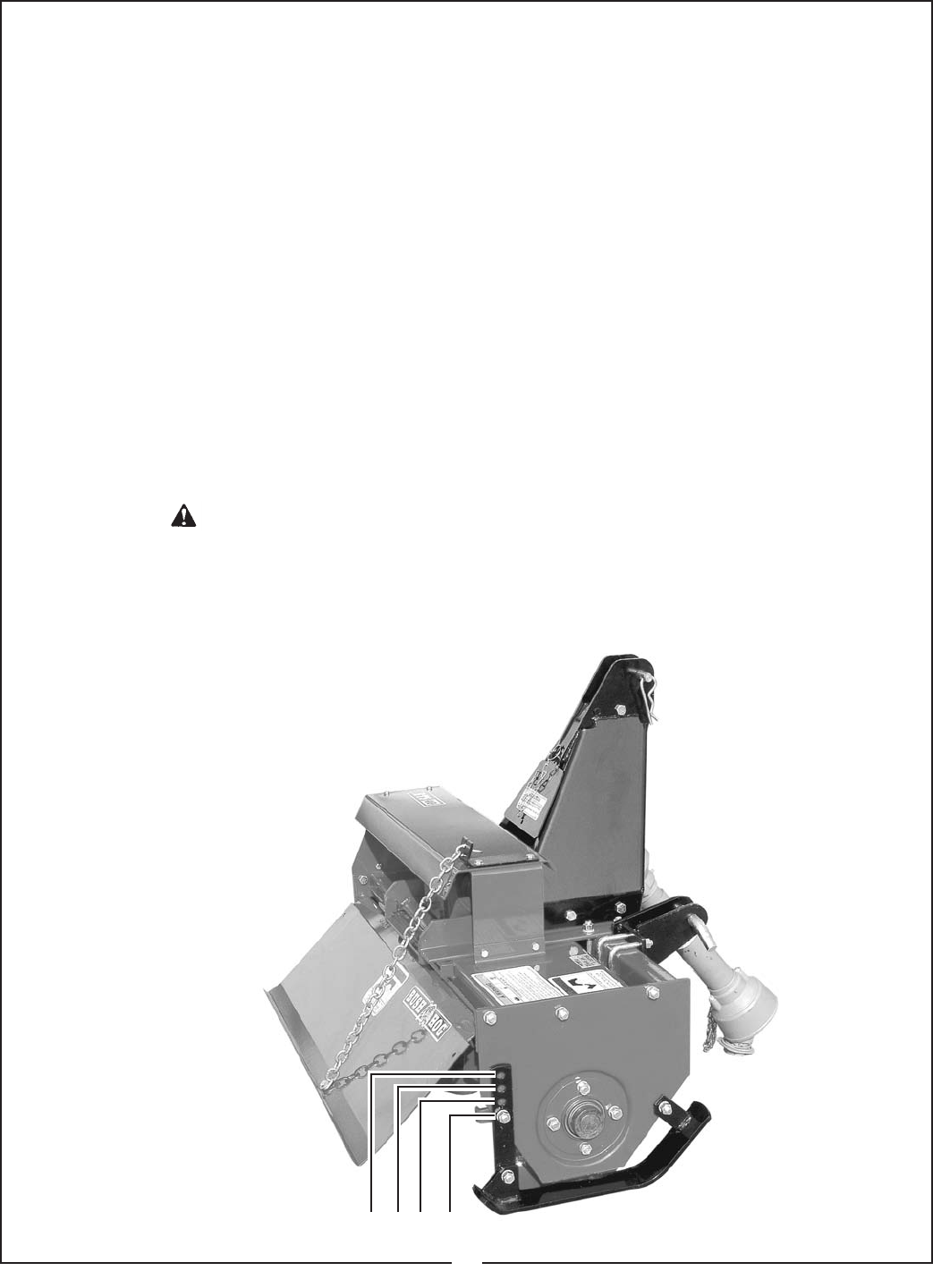

Figure 3-1

Skid Adjustment

1” 2” 3” 4”

SECTION III

OPERATING INSTRUCTIONS

3-1 GENERAL SAFETY

Only qualified people familiar with this operator’s

manual should operate this machine. Operator

should wear hard hat, safety glasses, and safety

shoes. The operator should read, understand and

practice all safety messages shown on the caution,

warning, and danger decals affixed to the tiller to

avoid serious injury or death. Use a rollover protec-

tive structure and seatbelt equipped tractor for all

operations. Before beginning operation, clear work

area of objects that may be picked up and thrown or

wrapped in tiller blades. Check for ditches, stumps,

holes, or other obstacles that could upset tractor or

damage tiller. Always turn off tractor engine, set park-

ing brake, and allow rotor to come to a complete stop

before dismounting tractor.

3-2 ADJUSTING FOR WORK

Depth of till is regulated by moving adjusting bolt

and adjusting skids up or down. (Figure 3-1) The

holes in the adjusting plate are in 1 inch increments

with the bottom hole being a 4 inch tilling depth.

Average soil with reasonable moisture will allow

depth of 4 inches in one pass with a tractor forward

speed of 2 mph. Heavy or packed soil may require

two passes to reach 4 inch depth. Using multiple

passes, a maximum depth of 7 inches may be

obtained.

Tractor forward speed and rear shield adjustment

(Figure 3-1) will regulate the finished results or tilth

of the soil. Traveling at the slowest forward speed

with the rear shield fully lowered will give finest pos-

sible finish. This shield adjustment is good for

mulching, mixing, and burying weeds, fertilizer, etc.

Tilled soil will become more coarse as forward

speed and shield height are increased. To leave

ground surface rough with larger clods and residue

exposed, work with shield fully raised. When working

in extremely rocky soil, It is recommended that

shield be in the raised position. A slip clutch avail-

able from your Bush Hog dealer is recommended for

extreme working environments.

Tiller may be offset as described in paragraph 2-2.

THE TILLER CAN FALL FROM HYDRAULIC

SYSTEM FAILURE. TO AVOID SERIOUS

INJURY OR DEATH, SECURELY SUPPORT

TILLER BEFORE WORKING UNDERNEATH.

WARNING