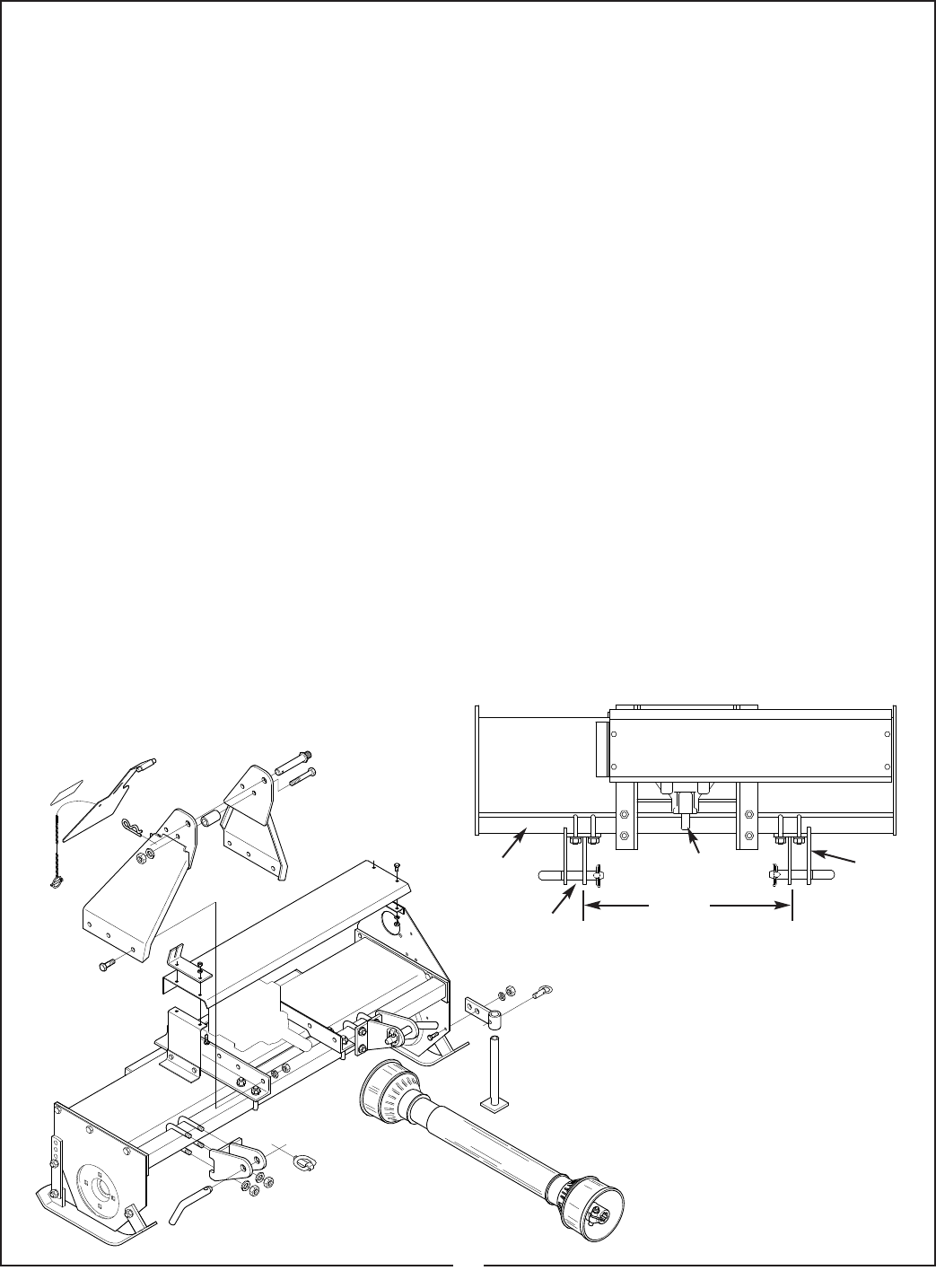

14

A. Insert parking stand onto mounting bracket

and retain with pin. Fasten parking stand bracket to

tiller end plate using two 3/8 x 1” bolts, lockwashers

and nuts.

B. Attach PTO driveline to gearbox input shaft.

Make certain driveline yoke is securely locked into

position and driveline shields are in place and in

good condition.

C. Fasten left and right mast struts to angle

bracket using six 1/2 x 1-1/4” bolts, lockwashers and

nuts. (Figure 5-1)

D. Loosely install one 3/8 x 3” bolt, spacer bush-

ing, lockwasher and nut between tops of mast struts.

E. Place rear access shield extensions into mat-

ing holes in rear of mast struts. Tighten the 3/8” bolt

to hold the shield in place.

F. Remove four bolts securing cross-shaft shield

to mounting brackets. Remove shield.

G. Fill gearbox to check plug with EP80W-90

gear oil.

H. Reinstall cross-shaft shield attaching chain

retainer to right end as shown n Figure 5-1.

I. Fasten one end of chain to rear deflector shield

using 3/8 x 1” bolt, flatwasher, lockwasher, and nut,

installing head of bolt to underside of shield. Install

opposite end of chain onto chain retainer, (Figure 3-

1)

J. Attach right and left hitch lugs to tiller frame

using four 1/2 inch U-bolts, lockwashers and nuts.

Space hitch lugs to dimensions shown in Figure 5-2.

K. Install hitch pins onto lugs securing with two

7/8” lockwashers and nuts.

L. Install top link into mast.

IMPORTANT

Before delivery to customer, perform SLIP CLUTCH

OPERATIONAL CHECK as described in Section 4-5,

page 12.

NOTE

It is important that the customer receive this opera-

tor’s manual with his machine. Safe and satisfactory

performance of this machine depends on the opera-

tor knowing the correct operating and maintenance

procedures. The customer should be reminded to fill

out and mail in the warranty registration card within

ten days of purchase.

Figure 5-1 Exploded Assembly

Figure 5-2 Hitch Lug Dimension

Clamp

Bolts

Gearbox

Input Shaft

Frame

Hitch Point

Hitch

Lugs

26-7/8”

11. After completing assembly, be sure that all safety locking devices or guards are in place.

12. Before operating the machine, thoroughly read the operation section of this manual.

13. Before operating, read the maintenance section of this manual to be sure that any parts requiring

lubrication such as gearboxes are full to avoid any possible damage.

BEFORE OPERATING THE EQUIPMENT, IF YOU HAVE ANY QUESTIONS REGARDING THE PROPER

ASSEMBLY OR OPERATION, CONTACT YOUR AUTHORIZED BUSH HOG DEALER OR REPRESENTATIVE.