12

SECTION III

MAINTENANCE

WARNING

BEFORE PERFORMING MAINTRENANCE

INSPECTIONS OR WORK ON CUTTER,

SHUT CUTTER ENGINE OFF AND DIS-

CONNECT SPARK PLUG WIRE. FAILURE

TO DO SO COULD RESULT IN ACCIDEN-

TAL STARTING OF ENGINE CAUSING

POSSIBLE INJURY OR DEATH.

3-1 MAINTENANCE CHECK LIST

Perform scheduled maintenance as outlined below.

Shut down engine, disconnect spark plug wire, and

disconnect battery pigtail harness before doing main-

tenance inspections and work. For engine mainte-

nance see Engine Owner’s Manual. All bolts should

be torqued as recommended in Torque Chart unless

otherwise specified.

BEFORE EACH USE

1. Check engine oil level. Add oil as necessary per

engine owner’s manual.

2. Check engine fuel level, add as necessary. Allow

engine to cool before filling. Use only approved

funnel and container to handle gasoline. Do not

fuel tank indoors. Wipe up spilled gasoline.

3. Inspect blade belt for tightness and wear. Tighten

if necessary per paragraph 3-2.

4. Check blade for sharpness and damage. If dull,

sharpen at a 45 degree angle on a bench grinder.

Make certain blade is balanced before rein-

stalling. If blade is bent, broken, or worn out,

replace with a genuine Bush Hog replacement

blade.

5. Check blade bolts for tightness. Tighten 3/4 x

2-1/4” bolts to 297 ft./lbs. and the 1/2 x 2” bolts to

76 ft./lbs.

6. Check blade bar nut for tightness. Tighten to 750

ft./lbs.

7. Make certain the cutter deck enclosed sides are

not damaged, bent or missing. Make necessary

repairs before operating cutter.

8. Make certain belt shield is in place and in good

condition.

9. Clean any debris from the safety decals and

check decals for legibility. Replace any missing or

illegible decals. Read and heed the safety decal

messages.

10.During operation, listen for abnormal sounds

which might indicate loose parts, damaged bear-

ings, or other damage. Repair or replace as nec-

essary.

40 HOURS

1. Grease blade hub assembly using grease gun

and multi-purpose grease until grease purges out

top seal. Wipe away excess grease to prevent

contact with belt.

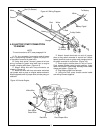

3-2 BELT ADJUSTMENT

A. Remove belt shield.

B. Check belt tension as shown in Figure 3-1. If

belt needs adjusting, proceed to step “C”. If not,

reinstall belt shield.

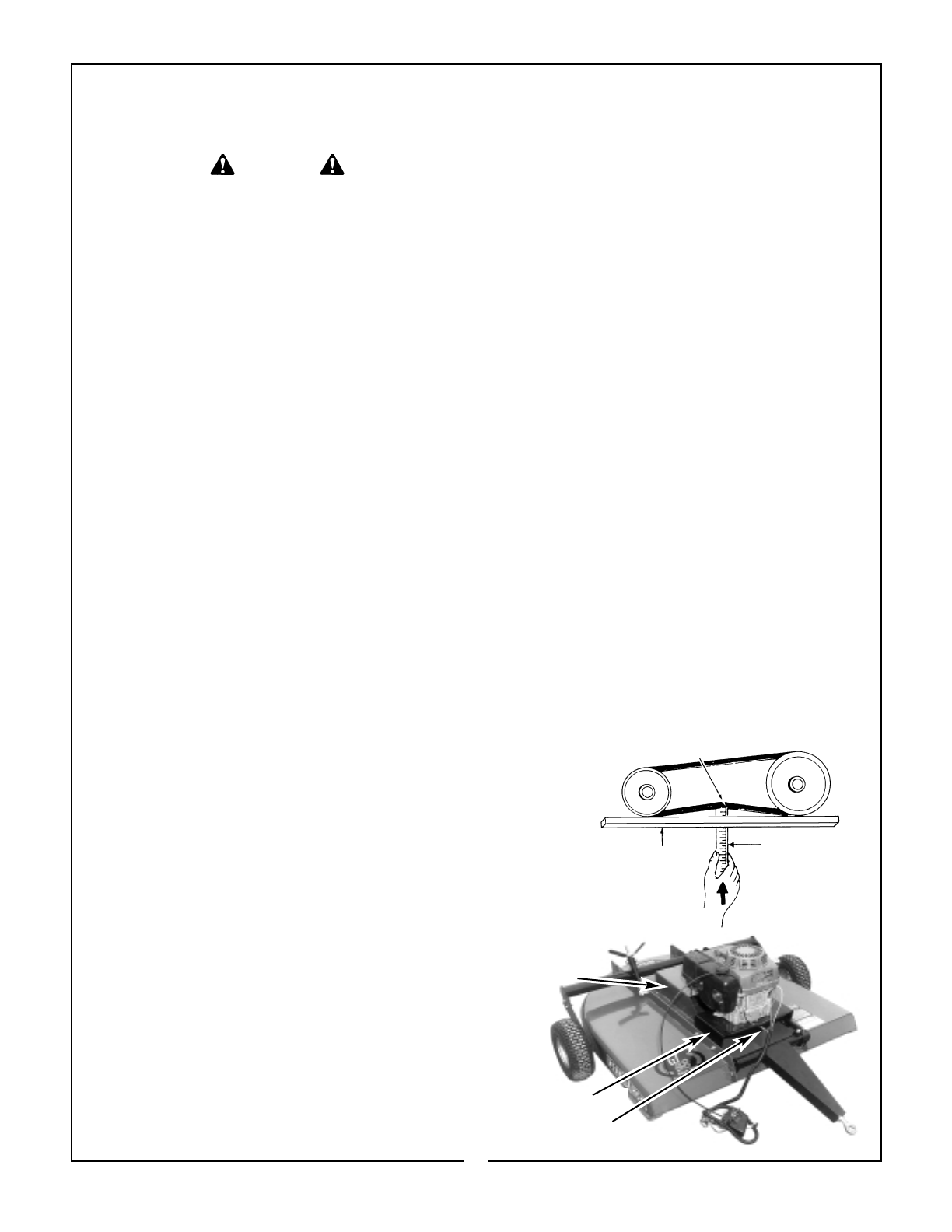

C. Loosen four bolts securing engine stand to

deck weldment. (Figure 3-2)

D. Turn adjusting bolt located at front of engine

stand clockwise to tighten belt, counterclockwise to

loosen belt. Place enough tension on belt to allow

not more than 1/2” and not less than 1/4” deflection.

(Figure 3-1) If a belt tension gauge is available, set

to 120 lbs. of tension.

E. Tighten four engine stand bolts.

F. Reinstall Shield.

3-3 REPLACING BELT

A. Remove belt shield. (Figure 3-2)

B. Loosen four bolts securing engine stand to

deck weldment.

Figure 3-1

Belt Deflection

Approximately 1/4”

Straight Edge

Ruler

4 lbs. of Force

Figure 3-2

Belt Shield

Engine Stand

Adjusting Bolt