Traction Drive Belt Adjustment

The traction drive belt is under constant spring tension and does

not require any adjustment. If the traction drive belt is slipping,

see your authorized dealer.

Speed Control Rod Adjustment

If the speed control rod requires adjustment, see an authorized

dealer.

Easy Turn™ Cable Adjustment

If the Easy Turn cable has stretched, the gears will not disengage

when the control lever is activated. Adjust the cable using the

following procedure.

1. Turn the engine off and remove the key.

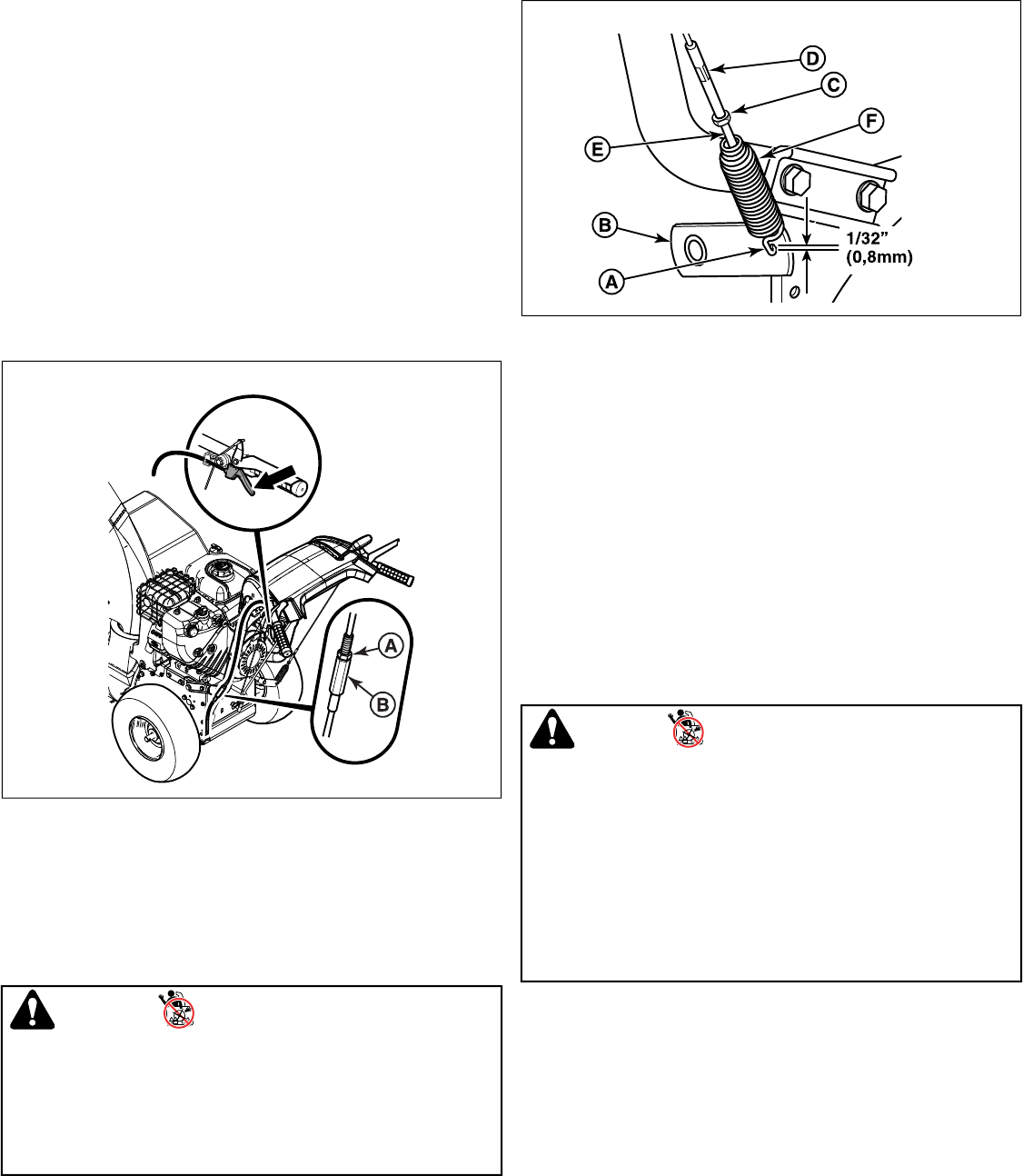

2. Loosen the jam nut (A, Figure 16).

16

3. Turn the adjustment nut (B) to lengthenor shorten the cable.

The cable should be tightened until all slack is removed from

the lever. However, it must not engage the Easy Turnwithout

depressing the control lever.

4. Tighten the jam nut (A).

Auger Cable Adjustment

WARNING

Amputation hazard

Over-tighten the auger cable may cause the auger drive to

engage without depressing the auger drive control.

Follow the adjustment procedure to ensure the cable is not

over-tightened.

1. With the auger control lever released, the hook (A, Figure

17) should barely touch the lever (B) without raising it. There

can be a maximum of 1/32" (0.8 mm) clearance.

17

2. To adjust, loosen the nut (C) by holding the adjusting flats

(D) and turning the nut. Then, turn the adjusting flats and

hold the adjustment screw (E). The adjustment screw is a

Phillips screw and the head can be heldor turned by inserting

a screwdriver through the spring (F).

3. Hold the adjusting flats and tighten the nut.

4. To ensure that the auger does not engage unlessthe control

is fully depressed, please perform the Safety System Tests.

The auger must stop within 5 seconds of the control

being released.

Determine Which Shear Bolt/Pin System

You Have

Please refer to the Illustrated Parts List to determine if your unit

requires a shear bolt or shearbolt and spacer combination.

DANGER

Amputation hazard

The discharge chute contains a rotating impeller to throw snow.

Fingers can quickly become caught and traumatic amputation

or severe laceration will result. Hand contact with the rotating

impeller inside the discharge chuteis the most common cause

of injury associated with snowthrowers.

Turn the engine OFF, wait for all moving parts to stop, and

remove the engine key before performing any maintenance or

repairs.

Shear Pin Replacement

Augers are secured to the auger shaft with special pins that are

designed to break if an object becomes lodged in the auger

housing. Use only factory spec, or equivalent, shear pins.

1. Turn off the engine and wait for all moving parts to stop.

2. Remove the existing shear pin.

3. Lubricate the auger grease fittings and rotate the auger to

lubricate the auger shaft.

NOTE: Some models are not equipped with grease fittings and

are exempt from this step.

16

Not for

Reproduction