13

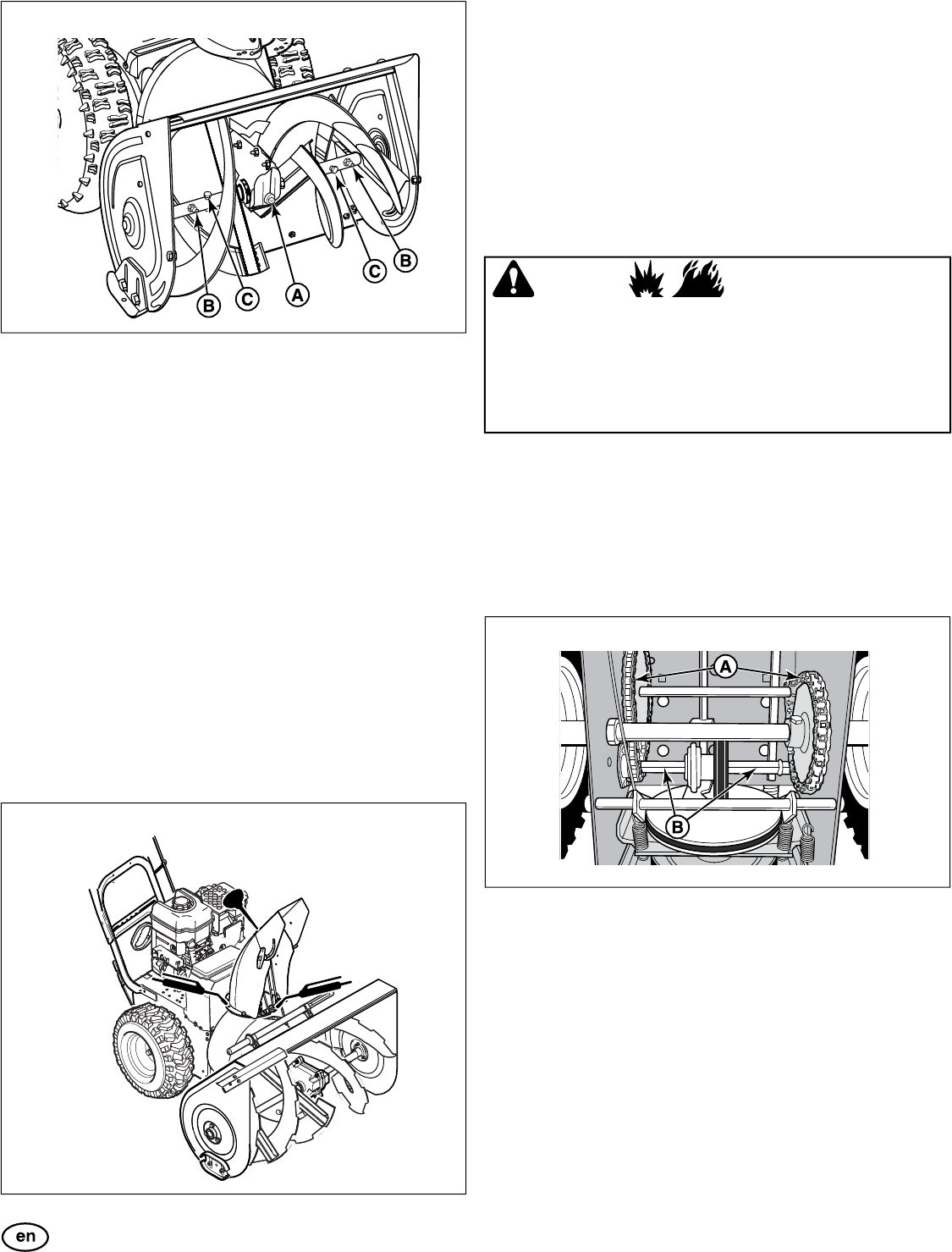

Lubricate Auger Shaft Fittings

Using a grease gun, lubricate the auger shaft fittings (B, Figure

13) every 25 operating hours, or once per season. Each time a

shear bolt or pin (C) is replaced, the auger shaft MUST be

greased.

For storage or when replacing shear bolts or pins, remove the

shear bolts or pins (C), lubricate the shaft fittings (B), and rotate

the augers several times to distribute the grease. Reinstall the

shear bolts or pins when complete.

NOTE: Some models are not equipped with grease fittings and

are exempt from these requirements.

Discharge Chute and Deflector Lubrication

Lubricate the chute rotation gear (Figure 14) with grease, and

the deflector mechanism with automotive type oil every twenty

five operating hours.

Where an oil can is pictured, lubricate with engine oil. Where a

grease gun is pictured, lubricate with lithium grease.

14

Hex Shaft and Chain Lubrication

NOTICE

Do not allow grease or oil to contact the rubber friction wheel

or the disc drive plate. If the disc drive plate or friction wheel

come in contact with grease or oil damage to rubber friction

wheel will result.

If grease or oil comes into contact with the disc drive plate or

friction wheel, make sure to clean plate and wheel thoroughly

with an alcohol based solvent.

1. Position speed select lever in the first forward gear.

2. Drain fuel to an approved container.

WARNING

Fire and explosion hazard

Gasoline is highly flammable and its vapors are explosive.

Drain gasoline outdoors, away from fire and other ignition

sources. Wipe up any spills immediately. Do NOT allow open

flame, smoking, or matches in the area.

3. Stand the snowthrower up on the auger housing end.

NOTE: When the crankcase is filled with oil, do not leave the

snowthrower standing up on the auger housing for an extended

period of time.

4. Remove the bottom panel.

5. Lubricate the chains (A, Figure 15) with grease.

15

6. Wipe the hex shaft (B) with 5W30 synthetic motor oil, before

storage and at the beginning of each season.

7. Install the bottom panel.

Traction Cable Inspection

The cables are adjustedat the factory and no adjustment should

be necessary. However, if the cables have become stretched or

are sagging, adjustment will be necessary. Please see your

dealer for this adjustment.

15

Not for

Reproduction