Maintenance

11

All the components used to build this engine must

remain in place for proper operation.

CAUTION

Emissions Control

Maintenance, replacement, or repair of the emissions

control devices and systems may be performed by

any non-road engine repair establishment or

individual. However, to obtain no charge repairs under

the terms and provisions of the Briggs & Stratton

warranty statement, any service or emissions control

part repair or replacement must be performed by a

factory authorized dealer. See the Emissions

Warranty.

Inspect Muffler And Spark Arrester

Inspect the muffler and the spark arrester (if

equipped) every 50 hours. If muffler is equipped with

a spark arrester screen, remove the screen for

inspection. Replace the screen if damaged or

plugged. If inspection determines that replacement

parts are required, make sure to use only original

equipment replacement parts.

Carburetor Adjustment

Never make adjustments to the carburetor. The

carburetor was set at the factory to operate efficiently

under most conditions. However, if adjustments are

required, see any Authorized Briggs & Stratton

service dealer for service.

The manufacturer of the equipment on which this

engine is installed specifies top speed at which the

engine will be operated. DO NOT EXCEED this

speed.

CAUTION

Valve Clearance

Check valve clearance every 250 hours. See

“Tune-up Specifications” chart.

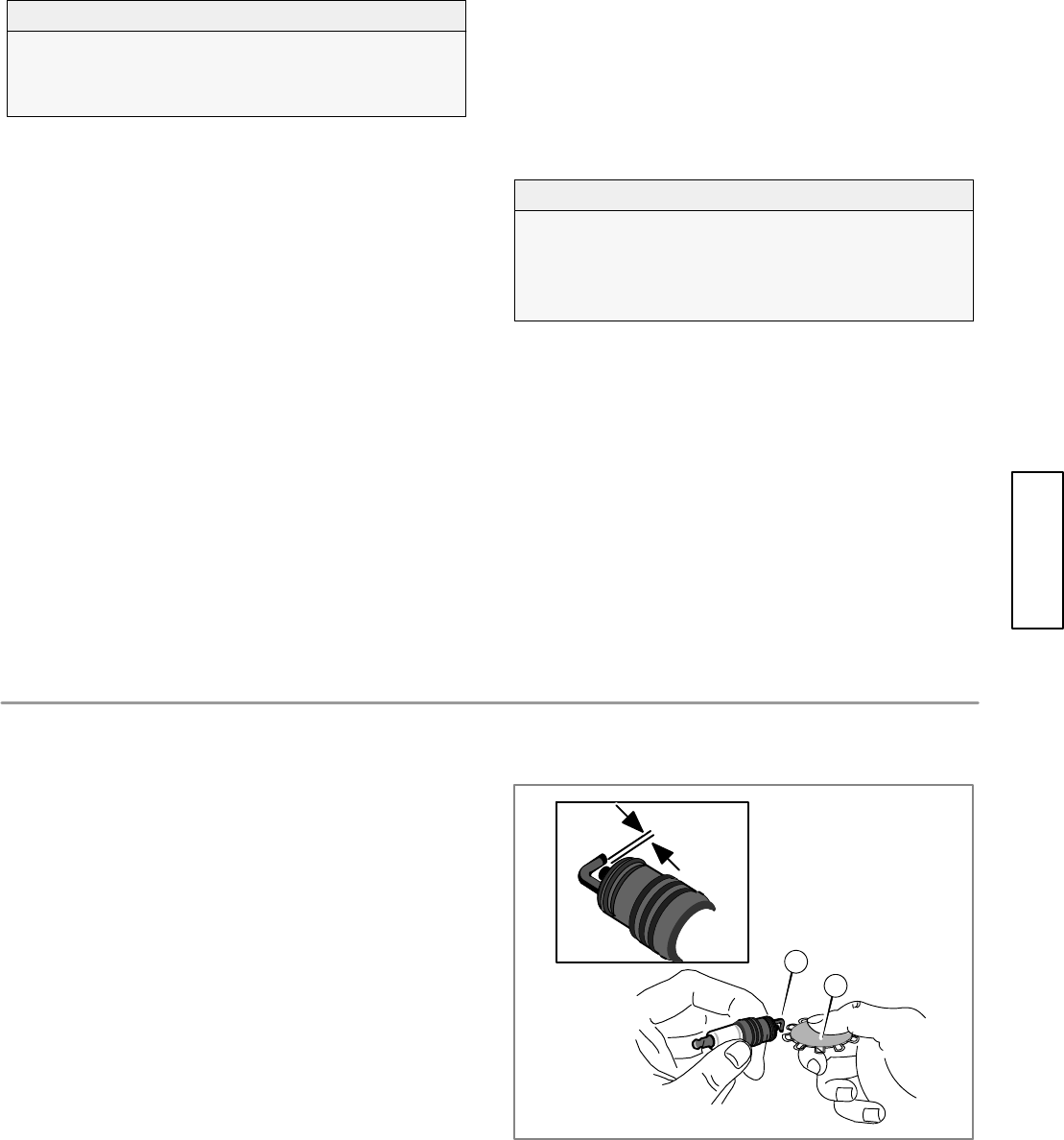

Spark Plug (Figure 15)

Check the spark plug every 100 hours. Replace the

spark plug if, upon inspection, the electrode (A) is

burned or worn. Make sure that the spark plug is

clean. Check the gap with a wire gauge (B). If

necessary, reset to .030 in (0.76 mm).

NOTE: In some areas, local law requires using a

resistor spark plug to suppress ignition signals. If this

engine was originally equipped with a resistor spark

plug, use same type for replacement.

.030 in

(.76 mm)

Figure 15: Check Spark Plug

A

B