12

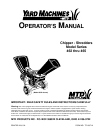

11. When reassembling the blade, tighten center

bolt to between 550 and 650 inch-pounds and

the two outer bolts to between 250 and 350

inch-pounds, or lacking torque wrench, tighten

securely.

Figure 10

SECTION 10: OFF-SEASON

STORAGE

Prepare your chipper-shredder for storage at the

end of the season or if the unit will not be used for

30 days or more. The following steps should be

taken to prepare your shredder for storage.

1. Clean and lubricate the shredder thoroughly.

2. Refer to engine manual for correct engine

storage instructions.

3. If storing an unventilated or metal storage shed,

coat metal parts with a light oil or silicone to

prevent rust.

4. Store in a cool dry place. Do not store next to

corrosive materials such as fertilizer.

SECTION 11: TROUBLE SHOOTING GUIDE

Note: For repairs beyond the minor adjustments above, contact your local authorized service dealer.

1. Insert screw driver through hole

2. Blade should be parallel to ground

Screw

Driver

Ground

Blade

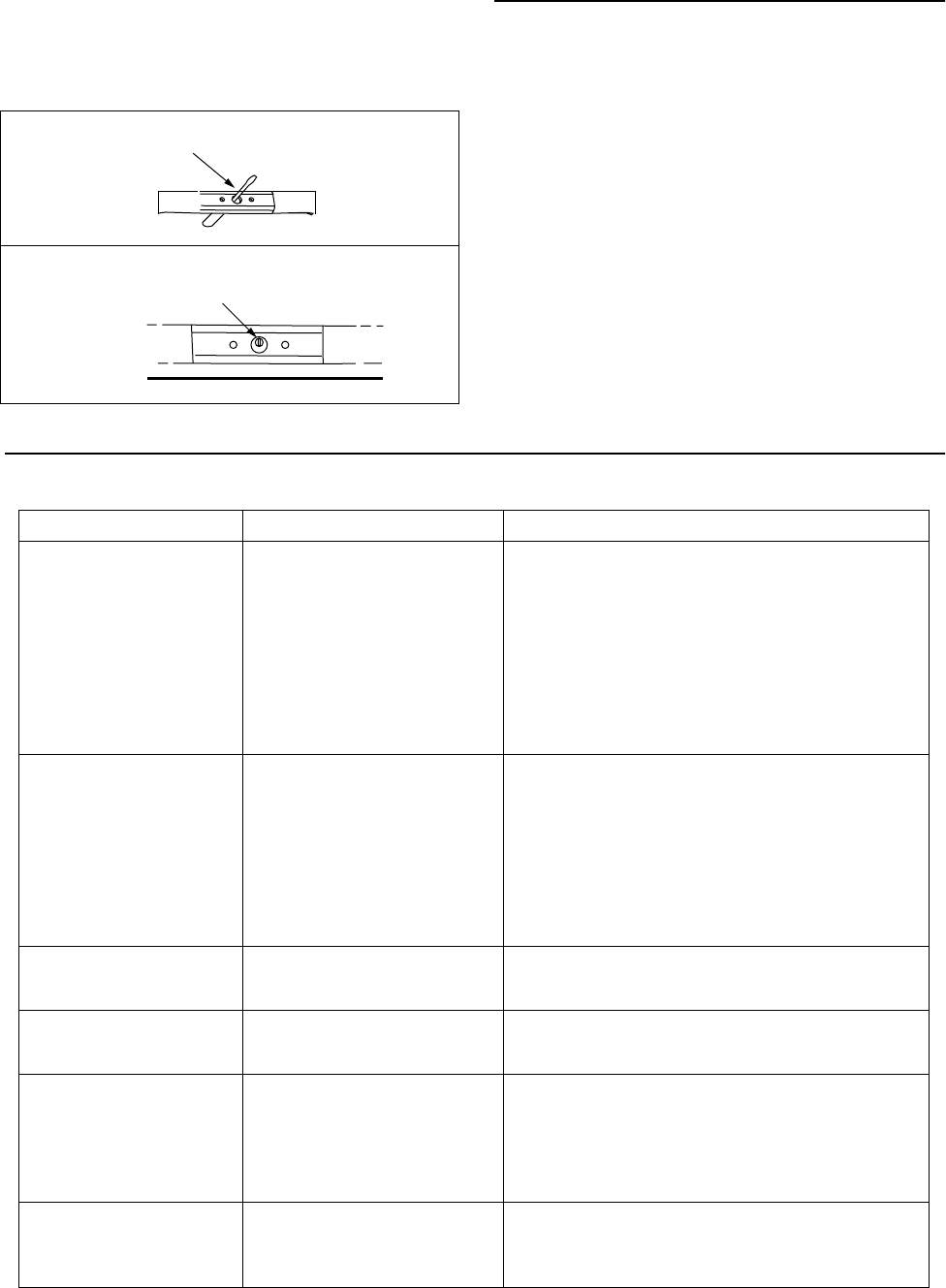

Trouble Possible Cause(s) Corrective Action

Engine fails to start Dirty air cleaner.

Choke not in ON position.

Spark plug wire disconnected.

Cannot pull recoil cord.

Fuel tank empty, or stale fuel.

Fuel shut-off valve closed (if so

equipped).

Faulty spark plug.

Refer to the engine manual packed with your unit.

Move switch to ON position.

Connect wire to spark plug.

Obstruction lodged in impeller. Stop immediately and

disconnect spark plug wire. Remove lodged object.

Fill tank with clean, fresh gasoline. Fuel will not last

over thirty days unless a fuel stabilizer is used.

Open fuel shut-off valve.

Clean, adjust gap or replace.

Loss of power; operation

erratic

Spark plug wire loose.

Unit running on CHOKE.

Blocked fuel line or stale fuel.

Water or dirt in fuel system.

Carburetor out of adjustment.

Dirty air cleaner.

Connect and tighten spark plug wire.

Move choke lever to OFF position.

Clean fuel line; fill tank with clean, fresh gasoline. Fuel

will not last over thirty days unless a fuel stabilizer is

used.

Disconnect fuel line at carburetor to drain fuel tank.

Refill with fresh fuel.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Engine overheats Carburetor not adjusted properly.

Dirty air cleaner.

Engine oil level low.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Fill crankcase with proper oil.

Too much vibration Loose parts or damaged

impeller.

Stop engine immediately and disconnect spark plug

wire. Have unit serviced by an authorized service

dealer.

Unit does not discharge Discharge chute clogged.

Low engine RPM.

Foreign object lodged in

impeller.

Stop engine immediately and disconnect spark plug

wire. Clean flail screen and inside of housing. See

Maintenance section of this manual.

Always run engine at full throttle

Stop engine immediately and disconnect spark plug

wire. Remove lodged object.

Rate of discharge slows

considerably or composition

of discharged material

changes

Low engine RPM.

Shredding blade and/or chipper

blades dull.

Always run engine at full throttle

Replace shredding and chipper blades or see your

authorized service dealer.