Part No 830542 Form No F062007A

13

VQ Owner’s Manual

DRIVE

Chains and Belts are normal replaceable wear items. A new chain should not be used on worn sprockets. Sprockets

should be replaced when replacing chains.

MAINTENANCE

Brake Adjustment: As parking brake wears, the brake discs may eventually require adjustment. To adjust belt, remove brake

guard and tighten mounting nut that connects brake arm onto transmission. Adjust cable as required. Unit must freewheel with

brake off. DO NOT OVER ADJUST.

CHAIN ADJUSTMENTS (see pg. 17)

1. Remove guards and place a support underneath the back end of the machine to raise the back wheels off of the ground.

2. Inspect chain and sprockets for wear, lubrication and tension. Replace if badly worn or damaged.

CHAIN TENSION AND ALIGNMENT (see pg. 17)

3. To install a new chain, locate and remove the keeper clip of chain connecting link on inboard side of chain. Along with the

master link and remove the chain. Replace chain, master link and keeper clip. Make sure the open end of the clip is facing away

from the chain travel and that the clip is on the inboard side of the unit.

4. Check the alignment of the chain to ensure that the chain will not jump off of the sprockets by rotating the wheels while they

are off the ground. If the chain is aligned properly proceed to step 8.

5. Alignment is made by loosening the nuts on the rear wheel bearings, do not remove bearing carriage bolts, nuts or wheels.

6. With the bearings pressed fully outward against wheels, keeping axle square with engine base, align and tension chain for

proper travel in as straight of a line as possible. When the desired position is reached, slightly tighten front bearing bolts and nuts

first. Then slightly tighten rear bearings. (Note: Tightening the front bearing carriage bolts and nuts first, helps keep chain tight.)

7. Recheck chain alignment, tension and axle squareness. If ok, fully tighten front and then rear bearing screws. Repeat

adjustment steps if necessary.

8. Check chain tension and roll wheels to be sure there are no excessively tight areas in the chain. Readjust if necessary.

9. Reinstall chain guard and differential guard.

10. Reinstall spark plug wire.

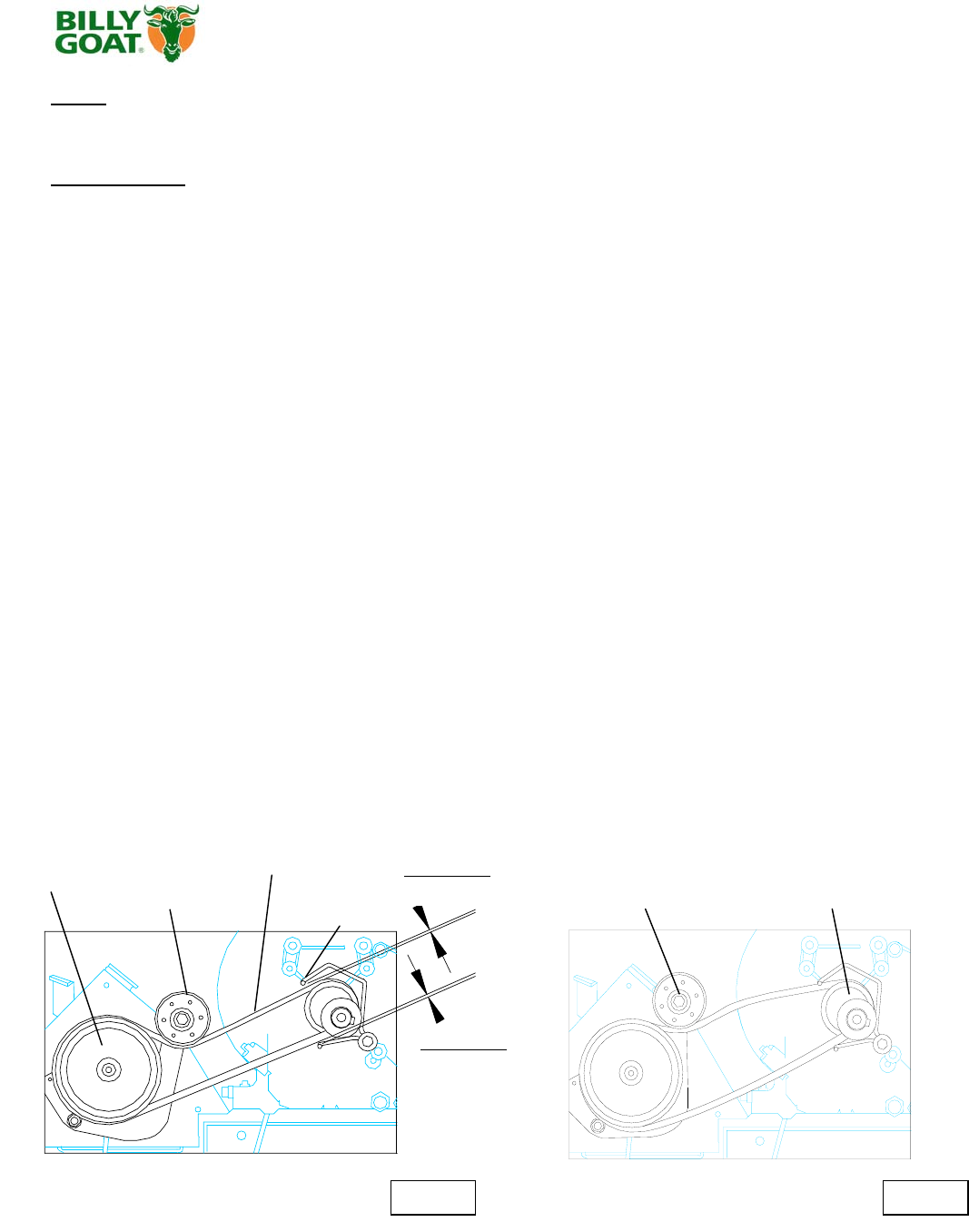

Belt Adjustment: As V-belt wears, adjustments may be required. Adjust by tightening or by loosening clutch cable nut as

required. When replacing the belt, the impeller must be removed. See instructions on page 12. See parts list for impeller bolt

torque specifications. See figure 10 & 11 for proper belt tension adjustment. If cable cannot be adjusted to provide proper belt

tension then belt must be replaced. DO NOT OVER ADJUST.

Chain Lubrication: With machine not running, oil chain using general S.A.E. 30 weight oil or chain lube every 10 hours or as

needed. Chain oiling hole is located in rear axle cover. Note: Be sure that entire length of chain is properly oiled. Oiling only a

few positions in the chain rotation will not properly oil the chain.

Transmission

pulley

Idler Pulley

in Drive

Position

Belt

Wire

Belt

guides

Idler Pulley

in neutral

position

Pulley

turns freely

0.06 (1.5mm)

0.125 (3.3mm)

0.06 (1.5mm)

0.125 (3.3mm)

Engaged drive position: Wire belt guides

should clear belt by 0.06” - 0.125”

(1.5mm – 3.3mm

Neutral position

Fi

g

. 10 Fi

g

. 11