Part No 830542 Form No F062007A

12

VQ Owner’s Manual

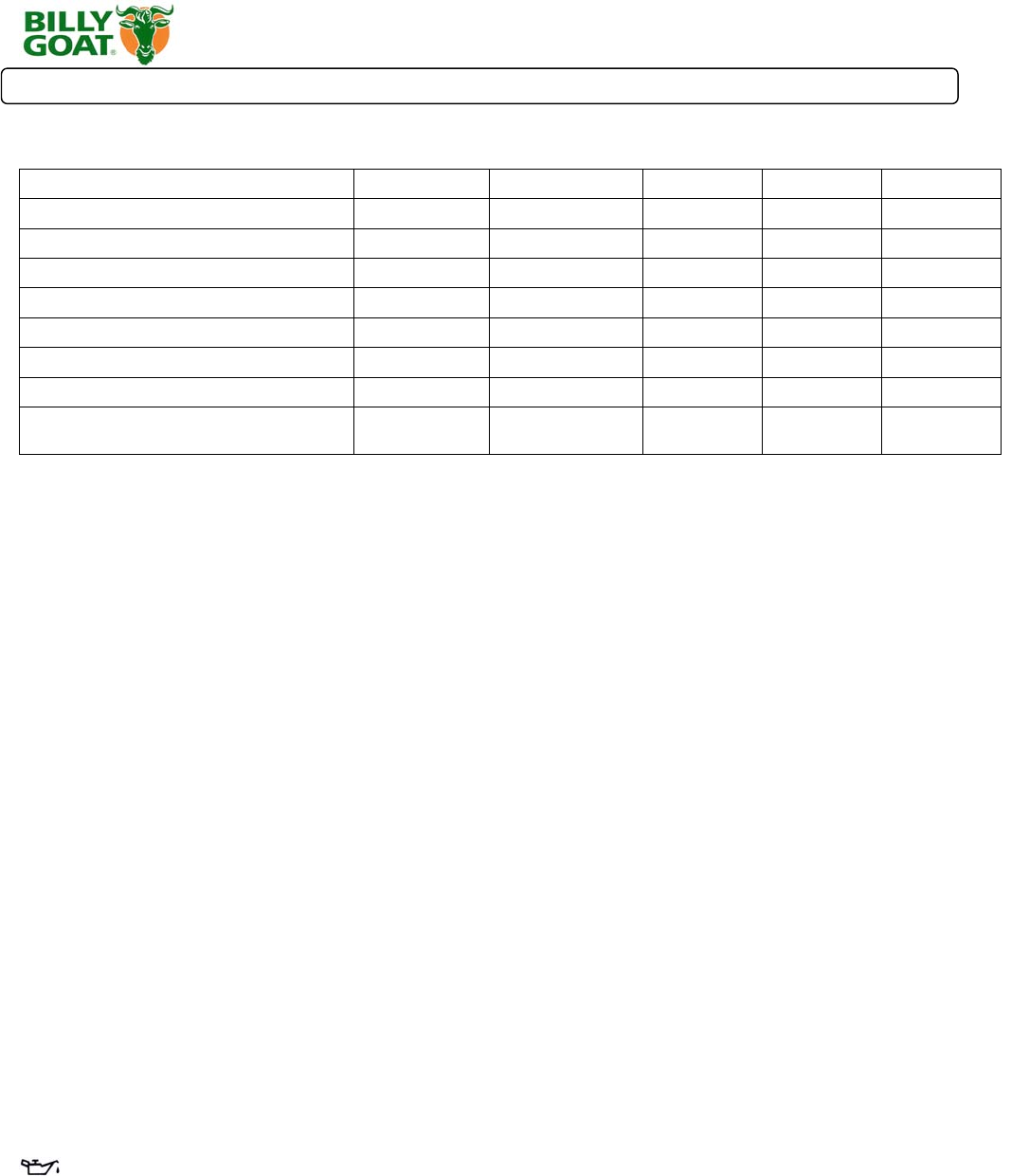

MAINTENANCE

P

ERIODIC MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Maintenance Operation Every Use (daily) Every 5 hrs (daily) Every 10 Hrs Every 25 Hrs Every 50 Hrs

Inspect for loose, worn or damaged parts.

z

Clean Debris bag and check strap tightness

z

Check Tire pressure

z

z

Engine (See Engine Manual)

Check for excessive vibration

z

Check belt adjustment (pg. 15)

z

Grease wheel zerks

z

Lubricate Drive chain and oil control pivot

points

z

Chain Lubrication: Using S.A.E. 30 weight oil or

equivalent. See maintenance schedule.

Grease: Wheels, Casters, and Rear Axle Bearings.

Tire air pressure: Check at regular intervals & maintain:

Rear SP 13" tires at 14 psi. (9.8 kPa).

IMPELLER REMOVAL

1. Disconnect spark plug wire.

2. Disconnect remote control rod from nozzle gobbler door.

3. Elevate front of machine using stable support blocks between housing and ground so that front caster wheels are

not touching ground.

4. Remove nozzle and caster wheel brackets from the housing.

5. Remove both the top and side belt guards between housing and transmission.

6. Loosen wire belt guide located on front face of engine on left side of unit between housing and engine.

7. Slide belt toward engine, out of belt groove in impeller hub drive pulley.

8. Remove impeller bolt and lock washer.

9. If impeller slides off freely, proceed to (step 12). (Do not drop impeller).

10. If impeller does not slide off crankshaft, place two crowbars between impeller and housing on opposite sides. Pry

impeller away from engine until it loosens. Using a penetrating oil can help loosen a stuck impeller.

11. If the impeller cannot be loosened, obtain a 1” (25.4mm) longer bolt of the same diameter and thread type as the

impeller bolt. Invert engine and impeller and support engine above ground to prevent recoil damage. Thread longer

bolt by hand into the crankshaft until bolt bottoms. Using a suitable gear or wheel puller against the bolt head and the

impeller back-plate (near the blades), remove impeller from shaft.

12. Slide impeller off of crank shaft and remove impeller from housing.

13. Reinstall new impeller and all applicable spacers, new impeller bolt and lockwasher in reverse order of removal.

(See the parts drawing on pages 16 and 17 for parts break-down and parts list on page 18 for proper impeller bolt

torque specifications and proper spacer for Honda engine only.)

14. When impeller is installed, slide belt into drive pulley and adjust wire belt guide as shown on page 13 (see fig. 10

& 11).

15. Reattach nozzle and both caster brackets in reverse order of removal.

16. Check operator's bail to ensure that it operates properly. (If not, see drive adjustments on page 13). Note: Drive

must completely disengage with bail released and must engage when bail is depressed within 1.0" (25.4mm) of the

operator's handle.

17. Reinstall all belt guards.

18. Reconnect spark plug wire.