1

PURPOSE

The Level Best Laser Grading Box is a cost-ef-

cient method for ne grading. Various capacities

sized to t the skid steer or tractor with a choice of

automatic control systems are available.

The Laser Grading Box is intended to operate with

an automatic control system providing accurate

grade control. If desired, the Laser Grading Box

can be operated without an automatic control

system in one of two ways:

Without any Valve/Manifold - The cylinder can

be connected directly to the tractor or skid

steer and the Laser Grading Box operated

using the tractor or skid steer valve. Flow to

the hydraulic cylinder is restricted to improve

control. However, movement of the cutting

edge can be coarse.

With the Valve and No Control System - A

switch can be installed to operate the electric

valve from the tractor or skid steer, providing

ne control of cylinder movement. However,

raising and lowering of the cutting edge is

dependant upon operator attentiveness and

accuracy.

For the most accurate control and ease of operation,

an automatic control system is used and recom-

mended. This manual is for a skid steer or tractor-

mounted, single cylinder Para-Level Laser Grading

Box with customer-supplied laser controls.

NOTE: Itistheresponsibilityofthedealeror

ownertoselect,install,andproperlyoper

-

ateanautomaticcontrolsystemonthis

LaserGradingBoxwithintheguidelinesof

thismanual.

Laser-guided depth control provides unmatched

measurement of plane from a single Rotating Laser.

Grade information from a Rotating Laser is pro-

cessed and automatically directs the grading box’s

hydraulics to maintain the elevation of the cutting

edge.

Most automatic control systems can operate auto-

matically or manually.

• In manual control, the operator watches an

indicator on the Laser Sensor or Control Panel

and uses the controls to keep the box “On

Grade”.

• In automatic control, the automatic control

system controls the box’s hydraulic cylinder to

keep the box “On Grade”.

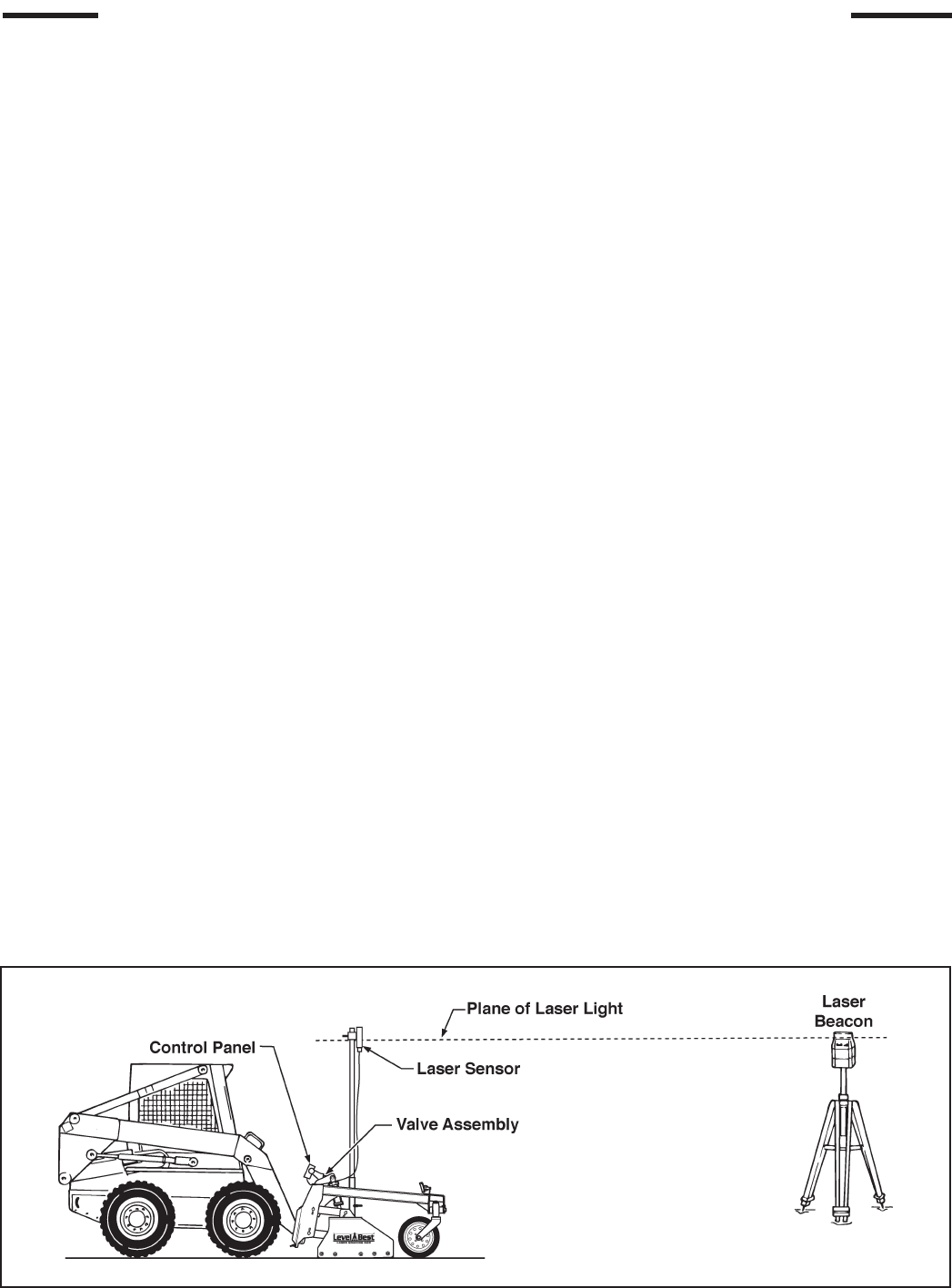

COMPONENTS

The control system consists of 4 components:

Rotating Laser – Provides a reference Plane of

Laser Light over the job site (refer to Figure 1).

Light plane may be level or set at an angle to

match the slope of the ground.

Laser Sensor – Mounted at a specic height on a

mast on the Laser Grading Box, it determines

the difference in depth based on the Plane of

Laser Light.

Figure 1. Plane of Laser Light with Components of the Automatic Control System

SYSTEMS FEATURES AND BASIC OPERATION